Advancements and Implementation of Innovative Heat-Pipe Low-Temperature Boiler Economizer

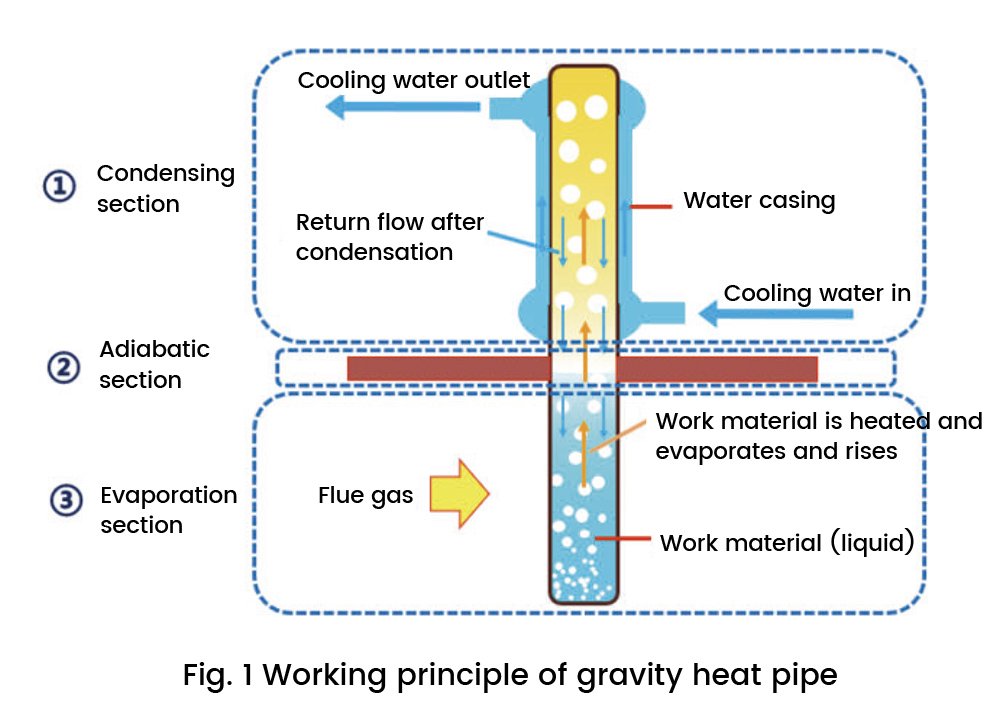

In the past decade, the implementation of low-temperature economizers downstream of air preheaters in coal-fired power plant boilers has gained significant traction as an effective energy-saving solution. This equipment aims to decrease the flue gas temperature from approximately 120 ℃ to 150 ℃ down to around 90 ℃. By doing so, it achieves a reduction […]

Waste Heat Utilization: Low-Temperature Boiler Economizer Layout Study

In recent years, the cost of power generation has been on the rise due to various factors, including fluctuations in coal prices and increased emphasis on environmental protection measures. Consequently, numerous power generation enterprises find themselves facing financial losses. To address these challenges and enhance the efficiency of coal utilization, power generation companies are actively […]

Solving Ash Accumulation and Coking Issues in Waste Incineration Power Plant Boiler Economizer: Analysis and Solutions

The high-temperature boiler economizer of the waste incineration power plant boiler in the circulating fluidized bed furnace is experiencing significant ash accumulation and severe coking. This has led to elevated exhaust gas temperatures. After approximately 25-30 days of operation, it becomes necessary to suspend furnace operations for treatment. Failure to address this issue promptly would […]

Waste Heat Boiler Economizer Replacement Construction Process

PetroChina Daqing Petrochemical’s heavy oil catalytic plant, with a capacity of 140×104 t/a, is equipped with two waste heat boilers. Each boiler is fitted with four sets of boiler economizers, comprising six sets weighing 28.1 t and two sets weighing 29.7 t. However, due to a decline in the heat exchange efficiency of the boiler […]

Optimizing Boiler Steam Consolidation: Impact of Boiler Economizer Outlet Water Temperature

Introduction: Unlocking the full potential of boiler steam consolidation is crucial for efficient and reliable operations. In this report, we delve into the critical aspect of optimizing boiler steam consolidation by examining the impact of boiler economizer outlet water temperature. We explore the challenges posed by decentralized heat down tubes and the absence of recirculation […]

Low Temperature Boiler Economizers: Design and Application in 330MW Coal-fired Units

The largest source of heat loss in boilers is associated with boiler exhaust. In the case of large and medium-sized boilers operating under normal conditions, exhaust loss typically represents 4% to 8% of the fuel heat input of the boiler. In active coal-fired thermal power units in China, the design temperature for coal-fired boiler exhaust […]

Expanding Horizons: Assessing the Thriving Boiler Economizer Market in Russia

Welcome to our report, where we delve into the thriving landscape of the Boiler Economizer market in Russia. In this comprehensive assessment, we explore the market’s size, growth potential, technological advancements, competitive landscape, regulatory framework, industry demand, challenges, emerging trends, and investment strategies. Join us as we navigate through the expanding horizons of the Boiler […]

5 Strategies for Boiler Economizer: Corrosion Control & Ash Reduction

In recent years, due to the increasing stringency of national environmental protection requirements, the emission standards for nitrogen oxides (NOx) from coal-fired power plants have significantly improved. Currently, the primary methods employed for denitrification in these plants are selective catalytic reduction (SCR) and non-selective catalytic reduction (SNCR). During the denitrification process, both SCR and SNCR […]

Maximizing Efficiency: H-Type Boiler Economizer in Industrial Boilers

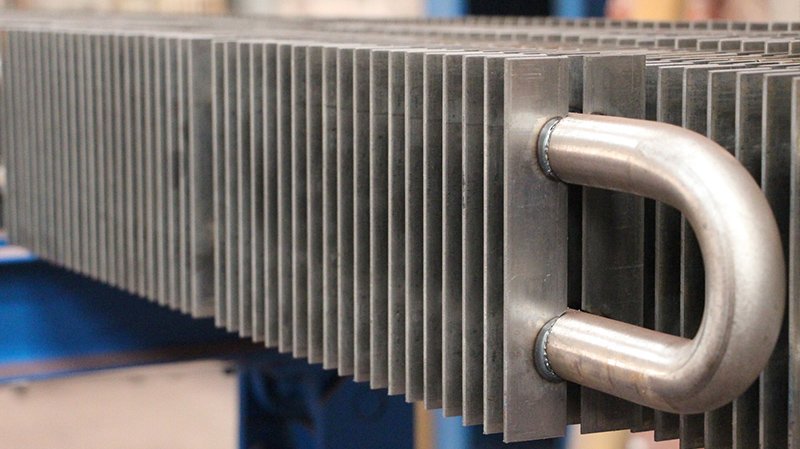

Most industrial boilers employ the SCR catalytic reduction method for denitrification, alongside controlling the coal combustion process. Typically, SCR systems require a flue gas temperature ranging from 570 to 720 K and are usually positioned after the convection bundle but before the coal saver. The catalyst arrangement typically follows a one-to-one pattern, necessitating the reservation […]

Boiler Economizer Wear and Tear: Effective Prevention Strategies Revealed

Imagine a powerful ally within a boiler, tirelessly working to harness the remnants of fiery flue gas, while simultaneously taming the exhaust temperature and invigorating the feed water. This indispensable companion is none other than the boiler economizer, a vital cog in the boiler’s machinery. However, residing at the tail end of the system, the […]

2023 Harnessing Energy Efficiency: Exploring the Future of Boiler Superheaters in the US

In the quest for a greener and more sustainable future, energy efficiency has emerged as a paramount concern across industries. One critical component at the forefront of this endeavor is the boiler superheater, a vital cog in the complex machinery of energy generation. As the United States seeks innovative ways to optimize electricity production, understanding […]

Powering Progress: The Untapped Market for Boiler Superheaters in India

In a nation driven by rapid industrialization and an insatiable demand for energy, the role of boiler superheaters cannot be understated. These innovative devices hold the key to unlocking unprecedented levels of efficiency, performance, and sustainability in various industrial processes. The Situation of Indian Power Consumption is as Follows: India consumed 1229 terawatt-hours of electricity […]