In a nation driven by rapid industrialization and an insatiable demand for energy, the role of boiler superheaters cannot be understated. These innovative devices hold the key to unlocking unprecedented levels of efficiency, performance, and sustainability in various industrial processes.

The Situation of Indian Power Consumption is as Follows:

India consumed 1229 terawatt-hours of electricity in 2020. India generates electricity using fossil fuels, hydropower plants, solar, wind, gas, and nuclear power, among other sources. Gross electricity generation by fossil fuels is 1,114,702 GWh1

The gross electricity consumption per capita in FY2019 was 1,208 kWh. The electricity consumption by sector in FY2020 was as follows: residential 25.77%, industrial 41.16%, agriculture 17.67%, commercial 8.29%, traction 1.53%2

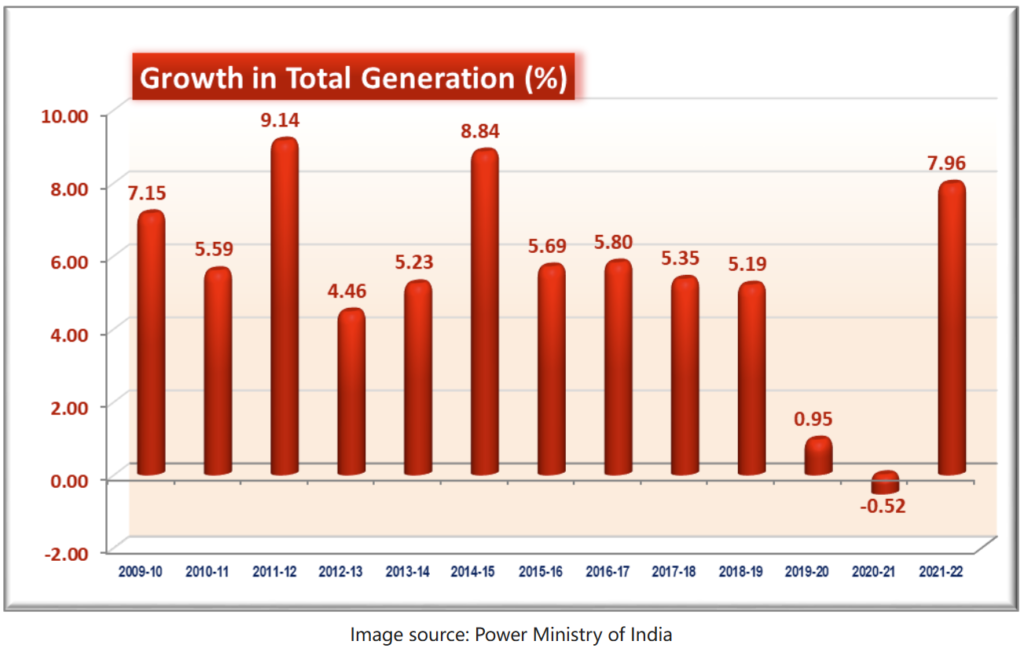

India’s power consumption is expected to grow at a compound annual growth rate of 5.1% from 2019 to 2024, driven by increasing urbanization, industrialization, and economic development. India’s power consumption is projected to reach 1,894 TWh by 20243

[Source]

Electricity sector in India – Wikipedia

India Energy Outlook 2021 – Analysis – IEA

Energy Consumption in India: The future of Energy Consumption in India

Power consumption in India(2019-2020) | Kaggle

What is the Situation of Indian Power Plants?

The situation of Indian power plants is very critical. More than half of the country’s 135 coal-fired power plants are running on fumes – as coal stocks run critically low¹. India is on the brink of an unprecedented power crisis, as it faces a surge in power demand, a drop in coal imports, and a lag in domestic coal production¹²³⁴. This threatens to derail India’s post-pandemic economic recovery, as well as its climate goals. If the crisis continues, India may face power blackouts, higher electricity prices, and inflationary pressures¹²³⁴. Experts say India needs to urgently address its over-dependence on coal and invest more in renewable energy sources¹²⁴.

[Source]

(1) Why India is on the brink of an unprecedented power crisis. https://www.bbc.com/news/business-58824804.

(2) India Energy Outlook 2021 – Analysis – IEA. https://www.iea.org/reports/india-energy-outlook-2021.

(3) India faces electricity crisis as coal supplies run critically low. https://www.theguardian.com/world/2021/oct/12/india-electricity-crisis-coal-supplies-critically-low.

(4) Explained: Why the coal shortage is choking thermal power plants. https://indianexpress.com/article/explained/india-coal-shortage-explained-7555184/.

The industrial boiler market in India was worth about $146 million in 2019 and is expected to grow at a compound annual growth rate of 6% to surpass $194 million by 2024. The market growth is attributed to the increasing demand for various industrial heating equipment across various process industries. The high demand for steam in chemical, power, and food industries is a key factor driving the market growth in the Asia-Pacific region .

India is a country with a population of 1.3 billion and a huge demand for electricity. The power demand in India is expected to be at least 191 TWh (terawatt-hours) by 2021-22 fiscal year, with a peak power demand of 298 GW (gigawatts). This provides a huge market opportunity for boiler manufacturers.

The Importance of Boiler Superheaters in Industrial Processes

In the realm of industrial processes, boiler superheaters hold paramount importance in enhancing efficiency, performance, and productivity. As a critical component within boiler systems, they play a pivotal role in ensuring the optimal utilization of energy resources and driving progress in various industries across India.

One of the key aspects that highlight the significance of boiler superheaters is their ability to elevate the temperature of steam generated by the boiler. By raising the steam temperature above its saturation point, superheaters enable the production of “superheated steam.” This superheated steam possesses several advantages over saturated steam, including enhanced energy transfer capabilities, improved process control, and increased thermal efficiency.

The increased energy transfer capabilities of superheated steam are particularly valuable in industrial processes that require high temperatures for specific operations. By utilizing superheated steam, businesses can achieve faster heating rates, precise temperature control, and improved product quality. Industries such as power generation, chemical manufacturing, food processing, and textile production heavily rely on the consistent and efficient delivery of superheated steam for their operations.

Furthermore, boiler superheaters contribute to the overall thermal efficiency of boiler systems. By superheating the steam, they reduce the moisture content within the steam, minimizing the energy losses associated with steam condensation. This translates into higher fuel efficiency, reduced fuel consumption, and lower greenhouse gas emissions. In a country like India, where energy resources are valuable and environmental sustainability is a growing concern, the adoption of boiler superheaters becomes a compelling proposition for industries seeking to optimize their energy usage and reduce their carbon footprint.

Moreover, boiler superheaters play a vital role in mitigating operational challenges and ensuring process stability. By maintaining a consistent and controlled steam temperature, they enable precise control of industrial processes that require specific temperature conditions. This level of control enhances product quality, reduces the risk of equipment damage, and ensures smoother and more reliable operations. Whether it’s for power generation, heat treatment, or industrial drying, the integration of boiler superheaters provides the necessary thermal stability for optimal process performance.

In summary, the importance of boiler superheaters in industrial processes cannot be overstated. Their ability to generate superheated steam, enhance energy transfer, improve thermal efficiency, and provide precise temperature control make them indispensable components in various industries. As businesses in India strive for increased productivity, energy efficiency, and environmental sustainability, the adoption of boiler superheaters emerges as a pivotal step towards powering progress and achieving excellence in industrial operations.

What industries require boiler superheaters in India?

In India, industries such as power generation, petrochemicals, food processing, textiles, paper and pulp, chemicals, automotive, and pharmaceuticals commonly require boiler superheaters. These industries rely on superheated steam for processes such as power generation, refining, sterilization, drying, fabric treatment, chemical reactions, and more. Boiler superheaters play a vital role in achieving precise temperature control, enhancing energy efficiency, and ensuring high-quality production in these sectors.

What are the main industries in India?

- India is the third largest electricity producer and the second largest electricity consumer in the world, with an installed capacity of 373.43 million kilowatts as of October 2020, ranking fifth in the world.

- India’s power plants mainly use coal as fuel, with coal power accounting for 52% of the total installed capacity, renewable energy accounting for 16%, hydropower accounting for 12%, nuclear power accounting for 2%, and gas and oil power accounting for 18%.

- India’s power plants face the dual challenge of coal supply shortage and electricity demand growth. By the end of September 2021, more than half of India’s power plants had less than a week’s coal stock, and six plants were completely cut off. The Indian government has taken emergency measures, such as increasing coal production and imports, lowering inventory targets, improving power generation efficiency and so on.

- India’s power plants are also actively developing renewable energy, especially wind and solar. According to the data from India’s Ministry of Energy, in 2020, India’s renewable energy installed capacity reached 87,900 megawatts, an increase of 12.4% year-on-year. The Indian government has set a target of achieving 175,000 megawatts of renewable energy installed capacity by 2022, and plans to increase the share of renewable energy in total power generation to 40% by 2030.

[Source]

- [A Talk on Foreign Power Industry (Asia) —- India – Zhihu – Zhihu Column]

- [India faces “coal emergency”: more than half of power plants have less than a week’s coal stock, six completely cut off]

- [EMIS Insights] India Power Industry Report 2018-2022 – Zhihu]

- [2022 Energy Industry Report: India’s Energy Economic Situation and Coal Supply and Demand Outlook | Natural Gas | Electricity_Netease Subscription]

- [India still supports coal-fired power generation – China Energy News]

The situation of electricity consumption by industry in India in 2023 is not available yet, as the data for the current fiscal year is still being collected and analyzed. However, based on the previous trends and projections, we can estimate the possible values for 2023.

According to the International Energy Agency, India’s electricity consumption is expected to grow at a compound annual growth rate of 5.1% from 2019 to 2024, reaching 1,894 TWh by 20242 Assuming a linear growth rate, we can estimate that India’s electricity consumption in 2023 will be around 1,700 TWh.

Using these estimates, we can calculate the approximate electricity consumption by industry in India in 2023 as follows:

| Industry | Consumption share in FY 2021 | Estimated consumption in FY 2023 (TWh) |

|---|---|---|

| Industrial | 41.16% | 699.5 |

| Domestic | 25.77% | 438.1 |

| Agriculture | 17.67% | 300.4 |

| Commercial | 8.29% | 141 |

| Traction and railways | 1.53% | 26 |

In India, several industries rely on boiler superheaters for their specific operational needs. Here are some of the industries in India that commonly require boiler superheaters:

Power Generation

India’s power sector heavily depends on thermal power plants for electricity production. These plants use boiler superheaters to generate superheated steam that drives turbines, producing power. Boiler superheaters play a crucial role in ensuring efficient power generation and maintaining the stability of the electrical grid.

Petrochemical Industry

India’s growing petrochemical industry requires boiler superheaters for various processes, including steam cracking, distillation, and refining. Superheated steam provides the necessary heat and temperature control required in these operations, enabling the production of chemicals, fuels, and other petrochemical products.

Food Processing

The food processing industry in India, encompassing sectors like dairy, beverages, snacks, and packaged food, relies on boiler superheaters for sterilization, drying, cooking, and other critical processes. Superheated steam ensures the highest standards of hygiene, efficiency, and product quality.

Textile Industry

India’s textile industry is one of the largest in the world. Boiler superheaters are integral to textile manufacturing processes, including dyeing, drying, and fabric treatment. They provide the necessary high-temperature steam required for efficient production and maintaining the desired fabric quality.

Paper and Pulp Industry

India’s paper and pulp industry utilizes boiler superheaters in various stages of production, such as drying the paper, running the paper machine, and performing chemical recovery processes. Superheated steam enables efficient paper production and contributes to environmental sustainability.

Chemical Industry

The chemical manufacturing sector in India extensively employs boiler superheaters for precise temperature control in different chemical processes. These processes include reactions, heat exchangers, and various other operations that require high-temperature steam.

Automotive Industry

India’s growing automotive sector utilizes boiler superheaters in manufacturing processes such as painting and surface treatment. Superheated steam helps achieve efficient and effective operations, contributing to high-quality automotive production.

Pharmaceutical Industry

The pharmaceutical manufacturing industry in India requires precise temperature and pressure conditions for various processes. Boiler superheaters provide the high-temperature steam necessary for sterilization, drying, and formulation in pharmaceutical production.

These are some of the key industries in India that rely on boiler superheaters. However, it’s important to note that boiler superheaters can have applications in any industry that utilizes steam for processes requiring high temperatures, temperature control, and energy efficiency.

Key Factors to Consider When Choosing a Boiler Superheater for Indian Market

Choosing the right boiler superheater for the Indian market requires careful consideration of several key factors. By taking into account these factors, businesses can ensure optimal performance, efficiency, and long-term value from their investment. Here are some essential aspects to consider when selecting a boiler superheater:

Performance and Capacity

Assessing the performance and capacity requirements is crucial. Factors such as steam flow rate, pressure, and temperature must align with the specific needs of the industry and application. It’s essential to choose a boiler superheater that can consistently deliver the desired superheated steam parameters to meet operational demands.

Compatibility and Integration

Compatibility with existing boiler systems is vital. The boiler superheater should seamlessly integrate with the existing infrastructure without compromising its overall performance or requiring extensive modifications. Considering factors like size, configuration, and connection compatibility will facilitate a smooth installation process.

Material Selection and Durability

The material used in constructing the boiler superheater should be suitable for the operating conditions and environment. It should withstand high temperatures, pressure, and corrosive elements that may be present in the specific industry. Opting for high-quality materials ensures longevity, reduces maintenance requirements, and enhances overall reliability.

Energy Efficiency and Environmental Impact

Energy efficiency is a crucial consideration for sustainable operations and cost savings. Look for boiler superheaters that maximize heat transfer efficiency and minimize energy losses. Additionally, consider the environmental impact, such as the emission of greenhouse gases, to align with India’s growing focus on environmental sustainability and regulatory requirements.

Maintenance and Serviceability

Evaluate the ease of maintenance and serviceability of the boiler superheater. Components that are accessible, easily inspected, and have straightforward maintenance requirements will minimize downtime and facilitate efficient operation. Additionally, consider the availability of spare parts and the support offered by manufacturers or suppliers.

Safety and Compliance

Safety should be a top priority when selecting a boiler superheater. Ensure that it meets all relevant safety standards and regulations to prevent accidents and ensure the well-being of personnel and equipment. Compliance with industry-specific guidelines, codes, and certifications is essential.

Cost Considerations

While cost should not be the sole determining factor, it is essential to evaluate the overall cost-effectiveness of the boiler superheater. Consider factors such as upfront costs, operating expenses, maintenance requirements, and the expected lifespan of the equipment. A thorough cost-benefit analysis will help make an informed decision.

Reputation and Support

Research the reputation and track record of the manufacturer or supplier. Look for testimonials, reviews, and references to gauge their expertise, reliability, and after-sales support. Engaging with reputable and experienced providers ensures a smooth procurement process and ongoing support throughout the lifecycle of the boiler superheater.

By carefully considering these key factors, businesses can select a boiler superheater that aligns with their specific requirements and optimizes performance, efficiency, and reliability in the Indian market. Investing time and effort in the evaluation process will ultimately contribute to long-term success and value for the organization.

Why DHB Boiler’s Superheater Reigns Supreme?

When it comes to selecting a boiler superheater that truly outshines the competition, one name rises above the rest: DHB Boiler. Renowned for their exceptional craftsmanship and cutting-edge technology, DHB Boiler’s superheater stands tall as the epitome of excellence in the industry.

Unleashing unrivaled performance, DHB Boiler’s superheater takes industrial processes to new heights. Its remarkable design ensures seamless integration, harnessing the power of innovation to enhance your operations. With a perfect balance between efficiency and capacity, this superheater surpasses expectations, providing a steady flow of superheated steam precisely tailored to your needs.

Crafted from top-tier materials, DHB Boiler’s superheater showcases a formidable durability that withstands the harshest operating conditions. Its robust construction guarantees a long lifespan, saving you from frequent maintenance woes and ensuring uninterrupted productivity.

Embracing the urgent need for sustainable solutions, DHB Boiler’s superheater boasts remarkable energy efficiency, minimizing waste and reducing your environmental footprint. As you embrace a greener future, this superheater paves the way for eco-friendly practices without compromising on performance.

The outside diameter of the pipe is generally 30-60mm. The convection superheater is the most commonly used, and the serpentine tube type is adopted. It has a relatively dense tube group, which is arranged in the flue of 450-1000 ℃ flue gas temperature, and is subject to the transverse and longitudinal erosion of flue gas. The flue gas mainly transfers heat to the pipe by convection, and some of it absorbs heat by radiation.

Specifications

| Description | Boiler superheater |

| Material | Alloy steel, Carbon steel etc. |

| Material standard | ASTM, EN or ISO etc.Structure Type |

| Tube | Coil |

| Dimension | Customization |

| Supply ability | 1000 ton per month |

| Manufacturing process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →Bending tube→Assembly→Inspection →RT→Heat treatment (annealing)→Hydraulic pressure test→Painting→ Packaging |

| Thermal Efficiency | Around 95% |

In conclusion, the untapped market for boiler superheaters in India presents a tremendous opportunity for industries seeking enhanced performance, energy efficiency, and operational excellence. By carefully considering the key factors discussed and selecting a reputable supplier, businesses can unlock the full potential of their operations and drive progress in the ever-evolving landscape. Embrace the power of boiler superheaters, empower your processes, and embark on a journey of unprecedented growth. The time is ripe to seize this opportunity and power up your progress with the remarkable capabilities of boiler superheaters. Let the untapped market fuel your success, propelling you to new heights of productivity and success.