Imagine a powerful ally within a boiler, tirelessly working to harness the remnants of fiery flue gas, while simultaneously taming the exhaust temperature and invigorating the feed water. This indispensable companion is none other than the boiler economizer, a vital cog in the boiler’s machinery. However, residing at the tail end of the system, the boiler economizer faces an arduous battle against the elements. You see, the flue gas temperature that permeates its chamber plummets to astonishing depths, triggering a dramatic transformation in the fly ash—transforming it into a hardened menace. Alas, this menacing fly ash relentlessly gnaws away at the tender tube walls of the economizer, leaving behind a trail of wear and damage. Alarming incidents have shown that the most frequent cause of boiler economizer tube bursts is none other than this relentless wear and tear. Urgent measures must be taken to fortify the boiler economizer against this unyielding onslaught. Failure to do so will result in the dreaded cycle of frequent tube replacements, escalating maintenance costs, and compromised efficiency. Safeguarding this vital part of the boiler becomes an utmost priority, guaranteeing its resilience and bolstering the overall performance of the entire system. For serious wear and tear, even 2-3 months need to replace the coal saver tube, thus increasing the maintenance cost of the boiler. Therefore, it is of great importance to strengthen the anti-wear of the boiler economizer.

Types of Wear of Boiler Economizer

In the realm of boiler operations, the flue gas journeys through the economizer with a purposeful flow, carrying within it a legion of fly ash particles. These tiny warriors, propelled by the forces of nature, wage a relentless battle against the resilient economizer tubes. Their ceaseless impact, forged over countless hours, leaves an indelible mark on the very fabric of the economizer. Time becomes a conspirator, as the abrasive dance between fly ash and tube unfolds, etching a story of endurance and survival. In the epic saga of the boiler economizer, this clash of elements bears witness to the profound effects of constant abrasion, forging a path that demands vigilance and fortification.

This can be divided into the following two cases:

- Let us delve into the captivating world where fly ash particles meet the surface of tube walls. Imagine a scenario where these particles approach the tube wall at a shallow angle, almost parallel. In such instances, we can analyze their impact by breaking it down into two distinct forces: one perpendicular to the tube wall’s surface and the other tangential. The perpendicular force causes the particle to wedge itself into the wall, while the tangential force facilitates its smooth sliding along the surface. The amalgamation of these forces creates an intriguing phenomenon—a cutting effect—where the particles leave their mark on the tube wall. Over time, as the boiler continues its operation, this relentless cutting effect exacts its toll, resulting in the loss of metal particles from the surface and consequent thinning of the tube wall. This form of wear, known as scouring wear, underscores the profound impact of particle-wall interactions within the intricate dynamics of boiler systems.

- Imagine a scenario where fly ash particles approach the surface of a tube wall at a steep angle, almost vertical in nature. With a remarkable velocity, these particles collide with the tube wall’s surface, triggering a fascinating chain of events. The sheer force of impact causes the tube wall’s surface to undergo a slight but noticeable plastic deformation. As time passes and numerous particles continue their relentless assault, the cumulative effect becomes more pronounced, exerting a substantial influence on the tube wall. Eventually, the layer of plastic deformation succumbs to the assault, detaching from the wall as a single entity, leaving behind a distinctive pattern of wear. This remarkable wear phenomenon is aptly named impact wear, a testament to the power unleashed when fly ash particles and tube walls collide.

Anti-wear Solutions

During the maintenance of the boiler economizer, it can be seen through careful observation that in actual boiler operation, the wear of fly ash particles on the tube wall is the result of a combination of the above two methods.

Through theoretical research and practical summary, the wear of fly ash particles on the tube wall is influenced by many factors, which mainly have two aspects of the coal saver tube and flue gas.

From the aspect of the coal saver tube, first, lies in the choice of what kind of material, if the choice of better performance of the material, the impact with the flue gas particles, the loss suffered less. Second, in the design of the boiler, the tube temperature needs to be controlled within a reasonable temperature range, although the surface of the tube wall there is a layer of oxide film, with the rise in temperature, the oxide film hardness increases, the amount of wear and tear decreases, but if the temperature is too high will lead to the oxide film off, and will increase the amount of wear and tear, so the selection of a reasonable working temperature is also very necessary. The arrangement of the third tube is also very important. For the downstream tube bundle, because the first row of tube bundle is facing the flue gas, the wear is very serious, while the first row of tube bundle behind the protection of the previous row, the wear will be much smaller; and for the wrong row of tube bundle, the second row of tube is facing the first row of tube between the two tubes, the ash particles into the tube bundle, the flow area is reduced, the flue gas accelerated impact on the second row of tubes, the wear is larger than the first row of tubes, and the subsequent rows are also subject to greater wear. The subsequent rows are also subject to greater wear and tear.

In terms of flue gas, there are many factors that determine the wear capacity of the flue gas.

First, the size of the fly ash particles in the flue gas, when the fly ash particles are small, the wear on the pipe wall is very small, when the fly ash particles gradually increase, the amount of wear increases, but if the fly ash particles are large to a certain extent, the rate of increase in wear tends to slow down.

Secondly, it lies in the number of fly ash particles per unit volume, the larger the number, the stronger the abrasion capacity of the pipe wall.

Third, the wear capacity of the flue gas is also related to the composition of the flue gas, when burning sulfur-containing fuel, sulfur trioxide in the flue gas in the heated surface wall temperature below the flue gas dew point will occur when the heated surface corrosion. Corrosion products are flushed away by the flue gas, the exposed metal surface and then corrosive, therefore, corrosion and wear alternately, so that the total wear is accelerated. Fourth, the impact of flue gas velocity, the speed of the flue gas and its ability to wear the pipe wall is directly proportional to. For example, in general, at the gap between the serpentine tube of the boiler economizer and the furnace wall, the flow rate of flue gas increases due to the reduction of the circulation area, so the wear here is larger than the general place.

When the boiler is in operation, the main factors affecting the wear of the coal saver tubes are the above-mentioned factors and some other factors. Considering the anti-wear of boiler economizer, the methods that can be considered mainly focus on some of the following aspects:

- When choosing the tube, you can use some tubes with better anti-wear performance or increase the wall thickness of the tube to improve the ability to resist wear.

- When making the general arrangement of the boiler, make the flue gas flowing through the boiler economizer have a reasonable flow rate, generally speaking, the flue gas speed at the tail heating surface of the boiler is 6 to 9 m/s. And make the boiler economizer tube work in a reasonable temperature range.

- In the selection of fuel, try not to choose those fuels with corrosive components, or choose fuels containing less corrosive components. And use finer coal powder to reduce the particle size of fly ash. Practice has proved that the addition of fly ash dust removal device in the boiler to remove part of the fly ash, can also reduce the wear capacity of the flue gas.

- Starting from improving the structure of the boiler economizer, adopting finned tubes and installing anti-wear devices can also improve the anti-wear ability of the boiler economizer. In practice, it is a common method to install anti-wear devices for coal economizer tubes, such as anti-wear covers and steel bars, which are mainly installed in the parts with more serious wear, such as the wall of the tube directly washed by flue gas, elbows and other parts. Adding steel bars to the coal saver tube has a certain effect on preventing wear, and has less effect on heat transfer. Adding anti-wear cover to the coal saver tube can isolate the flue gas and the tube to prevent them from direct contact, thus reducing the wear, which is a more common method nowadays.

Anti-wear Device of Boiler Economizer

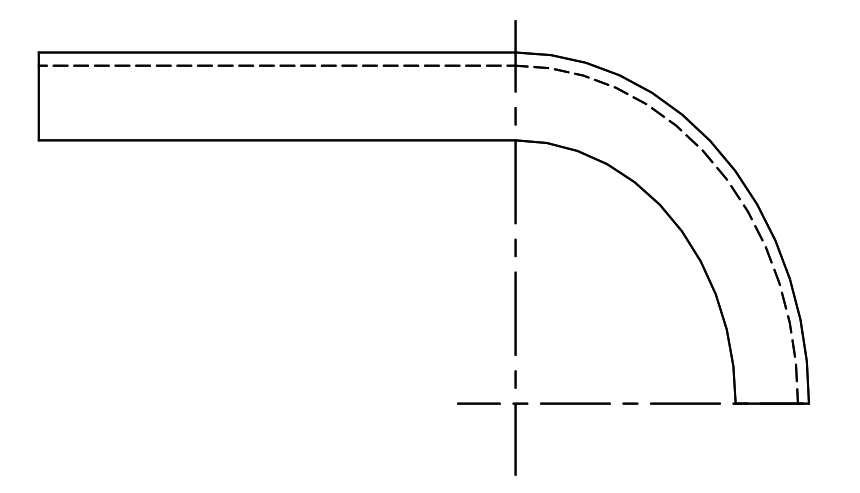

The following is an example of a 75-ton circulating fluidized bed boiler to introduce the anti-friction device of the boiler economizer. This boiler economizer is divided into two parts: low temperature boiler economizer and high temperature boiler economizer. The low-temperature economizer is a staggered structure, using ϕ32mm tube, material 20/GB3087, fins tube structure, fins using 5mm × 41mm flat steel, flat steel material Q235-A. The low-temperature economizer is arranged in the tail flue, flue gas from top to bottom flush tube, in the elbow near the furnace wall, are set up elbow-shaped anti-wear cover plate . The antifriction cover is made of steel plate with thickness of 3mm and made of Q235-A. The details are shown in the figure below:

On the straight section of the tube facing the flue gas washout, there is also an anti-friction cover arranged, which is designed in a 1/4 arc shape considering the fins on the tube, and each side of the fins is provided with such an anti-friction cover, forming a semicircle to protect the tube.

Technical Innovation Points

The high-temperature economizer takes on an even more demanding role as it finds its place within the fierce environment of the furnace chamber. To withstand the rigors of this setting, the serpentine tube within this economizer is expertly crafted using robust ϕ38mm tubes composed of high-quality 20G/GB5310 material. The flue gas, acting as an unyielding force, scours the tube from bottom to top, necessitating an ingenious countermeasure. Positioned beneath the tube lies an exceptional anti-abrasion steel plate, meticulously selected for its superior properties. Unlike the material employed in the low-temperature boiler economizer, this plate is forged from the formidable 1Cr20Ni14Si2 alloy. With such formidable defenses in place, the high-temperature economizer remains steadfast against the relentless scouring forces, ensuring sustained performance and longevity in the face of adversity.

In conclusion, understanding and effectively managing the wear and tear of boiler economizers is paramount for optimizing their performance and longevity. By considering factors such as fly ash particle size, quantity, flue gas composition, and velocity, we can implement targeted measures to mitigate wear and minimize damage. Furthermore, the careful selection of materials and the strategic arrangement of anti-friction devices play a vital role in enhancing the durability of economizers under various operating conditions. Through continuous research and innovation in anti-wear technologies, we can ensure that boiler economizers operate at their highest efficiency, contributing to energy savings, reduced maintenance costs, and a more sustainable future. By prioritizing anti-friction measures, we pave the way for a more reliable and resilient boiler system that meets the evolving demands of industry and supports our collective pursuit of efficient and responsible energy utilization.

Upgrade your boiler economizer today and experience enhanced durability and improved efficiency. Contact our experts to explore our range of anti-wear solutions and take your boiler performance to the next level.