Welcome to our report, where we delve into the thriving landscape of the Boiler Economizer market in Russia. In this comprehensive assessment, we explore the market’s size, growth potential, technological advancements, competitive landscape, regulatory framework, industry demand, challenges, emerging trends, and investment strategies. Join us as we navigate through the expanding horizons of the Boiler Economizer market in Russia, unlocking the opportunities that lie within.

Overview of Boiler Economizers: Understanding the Purpose and Functionality

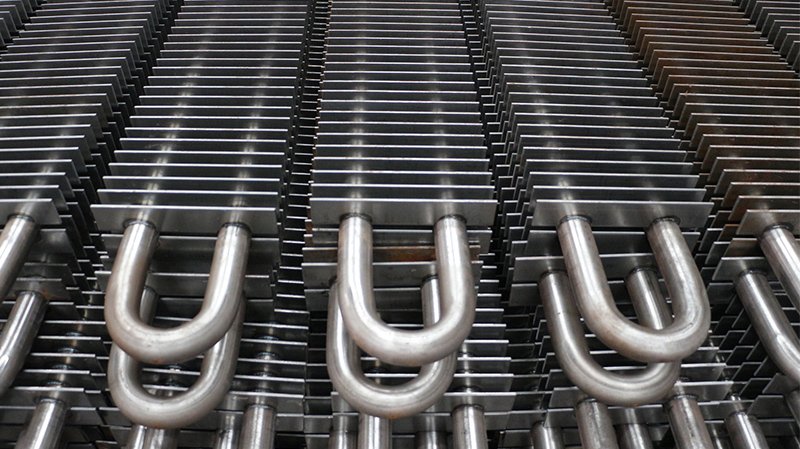

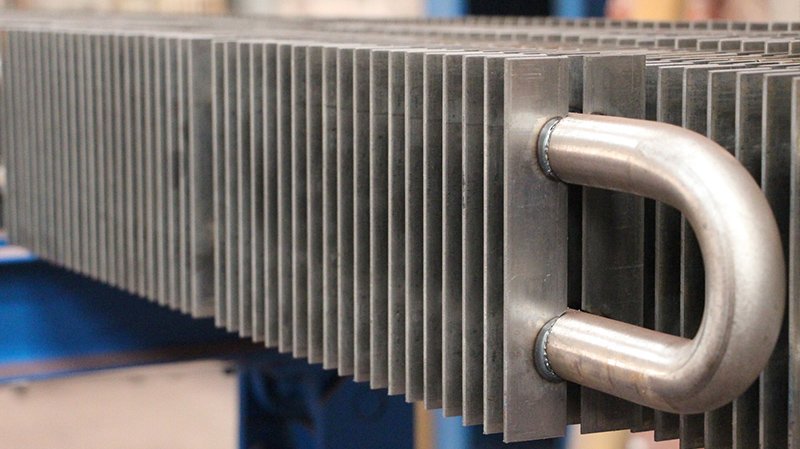

Boiler economizers are crucial for improving the energy efficiency of boilers. They recover waste heat from flue gases and use it to preheat incoming feedwater. By doing so, they reduce fuel consumption and greenhouse gas emissions. The economizer’s heat transfer mechanism involves passing flue gases through heat transfer surfaces, such as finned tubes, where heat is transferred to the feedwater. Different economizer designs exist, and advanced control systems optimize their performance. Overall, boiler economizers play a vital role in achieving sustainable and cost-effective boiler operations.

Market Size and Growth Potential of Boiler Economizers in Russia

The analysis report on the development trend and investment strategy of the global and Chinese boiler economizer industry from 2022 to 2028 predicts that the boiler economizer industry will benefit from environmental protection policies and energy-saving demand, and the market size and output value will maintain stable growth. Russia, as a resource rich country, also has significant market potential for boiler and economizer.

Moreover, government initiatives and energy efficiency programs play a crucial role in the market’s growth trajectory. The Russian government has implemented policies and regulations to promote energy-saving technologies, including incentives and subsidies for businesses investing in energy-efficient solutions like boiler economizers. For example, the Energy Efficiency and Energy Saving Program of Russia aims to reduce energy consumption in the industrial sector by promoting the adoption of energy-efficient technologies, including boiler economizers. These initiatives have created a favorable environment for market growth and encouraged the adoption of economizers across various industries.

Technological advancements in boiler economizers have also contributed to the market’s growth potential. Manufacturers are constantly innovating to improve the efficiency and performance of economizers. For instance, the integration of advanced materials, such as high-efficiency finned tubes and heat transfer surfaces, has enhanced the heat exchange capabilities of economizers, leading to improved energy savings. Additionally, the incorporation of intelligent control systems and real-time monitoring capabilities allows for better optimization of energy consumption and overall system efficiency.

Moreover, government initiatives and energy efficiency programs play a crucial role in the market’s growth trajectory. The Russian government has implemented policies and regulations to promote energy-saving technologies, including incentives and subsidies for businesses investing in energy-efficient solutions like boiler economizers. For example, the Energy Efficiency and Energy Saving Program of Russia aims to reduce energy consumption in the industrial sector by promoting the adoption of energy-efficient technologies, including boiler economizers. These initiatives have created a favorable environment for market growth and encouraged the adoption of economizers across various industries.

Technological advancements in boiler economizers have also contributed to the market’s growth potential. Manufacturers are constantly innovating to improve the efficiency and performance of economizers. For instance, the integration of advanced materials, such as high-efficiency finned tubes and heat transfer surfaces, has enhanced the heat exchange capabilities of economizers, leading to improved energy savings. Additionally, the incorporation of intelligent control systems and real-time monitoring capabilities allows for better optimization of energy consumption and overall system efficiency.

In conclusion, the market size of boiler economizers in Russia is experiencing robust growth, driven by the increasing demand for energy efficiency, cost savings, and compliance with environmental regulations. With the expanding industrial sectors, government support, technological advancements, and the retrofit market segment, the growth potential of the boiler economizer market in Russia is promising. As businesses strive to optimize their energy consumption, reduce emissions, and achieve long-term sustainability goals, the adoption of boiler economizers is poised to witness further expansion in the coming years.

Technological Advancements in Boiler Economizers and Their Impact on the Russian Market

Technological advancements in boiler economizers have played a significant role in shaping the Russian market and driving the adoption of these energy-efficient solutions. Manufacturers and researchers have been continuously innovating to improve the performance, efficiency, and overall effectiveness of boiler economizers, resulting in enhanced energy savings and reduced environmental impact.

One notable technological advancement in boiler economizers is the utilization of advanced materials in their construction. For instance, the incorporation of high-efficiency finned tubes and enhanced heat transfer surfaces has significantly improved the heat exchange capabilities of economizers. These materials offer increased surface area for heat transfer, allowing for more efficient energy recovery from the flue gases. Studies have shown that such advancements can improve boiler efficiency by up to 8%, resulting in substantial fuel savings.

Another area of technological advancement is the integration of intelligent control systems and advanced monitoring capabilities. These advancements enable real-time monitoring of key parameters such as flue gas temperature, feedwater temperature, and boiler load. Intelligent control systems can automatically adjust the operation of the economizer to optimize energy savings based on these parameters. Additionally, they can provide valuable data and insights for performance analysis and preventive maintenance, enhancing the reliability and longevity of the economizer.

Furthermore, digitalization and connectivity have revolutionized the operation and management of boiler economizers. The integration of IoT (Internet of Things) technologies allows for remote monitoring, control, and optimization of economizer performance. By leveraging data analytics and machine learning algorithms, operators can identify patterns, optimize operation, and detect potential issues or anomalies in real-time. This level of connectivity and data-driven decision-making has led to improved efficiency, reduced downtime, and enhanced overall system performance.

The impact of these technological advancements on the Russian market has been significant. The increased efficiency and performance of modern boiler economizers have attracted the attention of industries across various sectors, such as manufacturing, power generation, and oil and gas. The potential for substantial energy savings, along with the added benefits of reducing emissions and improving sustainability, has encouraged widespread adoption.

In conclusion, technological advancements in boiler economizers have had a profound impact on the Russian market, driving increased adoption and improving energy efficiency. Advanced materials, intelligent control systems, and digital connectivity have all contributed to enhanced performance, fuel savings, and environmental benefits. As technology continues to advance, the potential for even greater efficiency gains and optimization in boiler economizers is promising, further propelling the growth and adoption of these energy-saving solutions in Russia.

Key Players and Competitive Landscape in the Boiler Economizer Industry in Russia

The boiler economizer industry in Russia is characterized by a competitive landscape, with several key players operating in the market. These companies, including Shanghai Huazheng Boiler Co., Ltd, DHB Boiler Co., Ltd, and Sichuan Zhugen Boiler Co., Ltd, have established themselves as prominent providers of boiler economizer solutions. They offer a diverse range of innovative and high-quality products tailored to meet the specific needs of customers across various sectors.

Shanghai Huazheng Boiler Co., Ltd. is a professional enterprise engaged in the design, manufacturing, installation, debugging, and service of industrial boilers and their supporting equipment. The company’s main products include steam boilers, hot water boilers, thermal oil boilers, waste heat utilization equipment, etc. Among them, the economizer series products have the characteristics of high efficiency, energy conservation, low emissions, and compact structure. Sichuan Zhugen Boiler Co., Ltd, known for its focus on research and development, has introduced cutting-edge technologies to the market, resulting in highly efficient and performance-driven boiler economizers. Their advancements in materials and heat transfer designs have set them apart from the competition.

DHB Boiler Co., Ltd specializes in comprehensive energy solutions, including boiler economizers, and has emerged as a key player in the Russian market. Their customer-centric approach, combined with a wide range of customizable solutions, enables them to cater to the specific requirements of different industries. These key players, along with others, contribute to the competitiveness and growth of the boiler economizer industry in Russia through their technological expertise, product innovation, and dedication to customer satisfaction.

Regulatory Framework and Policies Shaping the Boiler Economizer Market in Russia

The boiler economizer market in Russia is influenced by a robust regulatory framework and policies aimed at promoting energy efficiency, reducing emissions, and ensuring sustainable industrial practices. The government has implemented several initiatives to drive the adoption of boiler economizers and incentivize businesses to invest in energy-saving technologies.

One key aspect of the regulatory framework is the establishment of energy efficiency standards and guidelines. The Russian government has set specific requirements and performance benchmarks for boiler systems, including the incorporation of economizers. These standards serve as a benchmark for manufacturers, ensuring that their products meet the required efficiency criteria. By mandating the use of economizers, the government encourages the reduction of energy consumption and greenhouse gas emissions in industrial and commercial sectors.

Moreover, the Russian government has implemented policies and programs to support the adoption of energy-efficient technologies, including boiler economizers. This includes financial incentives, subsidies, and tax benefits for businesses investing in energy-saving equipment. These initiatives aim to alleviate the initial investment costs associated with installing economizers and encourage the implementation of energy-efficient solutions. Such support mechanisms play a vital role in promoting the wider adoption of economizers across various industries in Russia.

Additionally, environmental regulations and emission standards have a significant impact on the boiler economizer market. The government has established stringent emission limits to curb pollution and mitigate the environmental impact of industrial activities. Boiler economizers contribute to the reduction of emissions by improving the overall energy efficiency of boiler systems. Businesses that comply with these regulations by installing economizers not only ensure environmental sustainability but also avoid penalties and fines associated with non-compliance.

Furthermore, the government’s long-term sustainability goals and commitments play a pivotal role in shaping the regulatory framework for boiler economizers. Russia has pledged to reduce greenhouse gas emissions under international agreements and has set ambitious targets for energy efficiency improvements. To achieve these goals, the government encourages the adoption of advanced technologies, including boiler economizers, to optimize energy consumption and reduce the carbon footprint of industrial operations.

Energy Efficiency Benefits of Boiler Economizers and Their Environmental Impact

Boiler economizers offer notable energy efficiency benefits and have a positive environmental impact. By recovering waste heat from flue gases, they reduce fuel consumption and lower greenhouse gas emissions. These devices improve boiler efficiency, leading to significant energy savings and cost reduction. Additionally, economizers contribute to mitigating climate change by reducing CO2 emissions and minimizing the release of pollutants such as NOx and SO2. Implementing boiler economizers aligns with global sustainability goals and environmental regulations, showcasing a commitment to energy efficiency and environmental responsibility.

Industries and Applications Driving the Demand for Boiler Economizers in Russia

Boiler economizers are in high demand across various industries in Russia, driven by their ability to enhance energy efficiency and reduce operational costs. Several key industries and applications have been instrumental in driving the demand for these energy-saving devices.

The manufacturing sector is one of the primary industries driving the demand for boiler economizers in Russia. Manufacturing facilities, including those in the steel, pulp and paper, chemical, and food processing sectors, heavily rely on efficient boiler systems to meet their operational needs. By integrating economizers into their boilers, these industries can optimize energy consumption and reduce fuel costs significantly. The ability of boiler economizers to recover waste heat from flue gases and preheat feedwater offers substantial energy savings, making them a valuable investment for manufacturers seeking to improve their energy efficiency.

The oil and gas industry also plays a crucial role in driving the demand for boiler economizers in Russia. With the country’s rich reserves and extensive extraction activities, energy-intensive processes are involved in exploration, production, and refining operations. Boiler systems are essential in these operations, and the integration of economizers helps optimize the energy efficiency of these systems. The ability to recover waste heat and reduce fuel consumption is of paramount importance in this industry, where energy costs and environmental impact are key considerations.

Furthermore, the power generation sector is a significant driver of demand for boiler economizers in Russia. Power plants rely on boilers to produce steam for electricity generation, and optimizing boiler efficiency is critical for cost-effective and sustainable power production. Boiler economizers enable power plants to recover heat from flue gases, improving overall energy efficiency and reducing fuel consumption. The energy savings achieved through the use of economizers have a direct impact on the operational costs of power generation, making them an attractive solution for the industry.

In summary, the demand for boiler economizers in Russia is driven by various industries and applications. The manufacturing sector, oil and gas industry, power generation sector, seek to enhance energy efficiency and reduce operational costs. Boiler economizers enable these industries to recover waste heat, optimize energy consumption, and achieve substantial fuel savings. As the importance of energy efficiency and cost reduction continues to grow, the demand for boiler economizers in Russia is expected to increase across a wide range of industries and applications.

Challenges and Opportunities in the Adoption of Boiler Economizers in the Russian Market

One of the key challenges in the adoption of boiler economizers is the initial investment cost. While boiler economizers offer long-term energy savings, the upfront expenses associated with installation and integration can be a barrier for some businesses. The cost of purchasing and retrofitting existing boiler systems with economizers, along with the required engineering and installation work, can pose financial challenges, especially for small and medium-sized enterprises. However, it is important to consider the long-term benefits and potential return on investment, as economizers can lead to substantial energy savings and reduced fuel consumption over their lifespan.

Another challenge is the complexity of integrating economizers into existing boiler systems. Each boiler installation may have unique requirements and configurations, necessitating careful engineering and retrofitting to ensure proper functionality and compatibility. Engaging experienced professionals and conducting thorough feasibility studies are essential to address technical challenges and ensure seamless integration. Additionally, proper maintenance and periodic cleaning of economizers are crucial to prevent fouling and maintain optimal performance, which can pose additional operational challenges.

Despite these challenges, the adoption of boiler economizers in the Russian market presents significant opportunities for businesses and industries. The growing emphasis on energy efficiency, cost reduction, and environmental sustainability creates a favorable market environment for economizers. By implementing these devices, businesses can reduce fuel consumption, lower greenhouse gas emissions, and enhance overall operational efficiency. This aligns with global sustainability goals and environmental regulations, positioning adopters of boiler economizers as industry leaders committed to responsible and sustainable practices.

Furthermore, the government’s support through incentives and subsidies encourages the adoption of energy-saving technologies, including boiler economizers. Taking advantage of these support mechanisms can offset the initial investment costs and make the adoption of economizers more financially viable. Moreover, the increasing availability of advanced technologies and materials for boiler economizers presents opportunities for innovation and improved performance. Manufacturers and suppliers can develop more efficient and cost-effective solutions, expanding the range of options available in the market.

Investment Strategies and Market Entry Opportunities in the Boiler Economizer Sector in Russia

Investment strategies and market entry opportunities in the boiler economizer sector in Russia present lucrative prospects for businesses looking to capitalize on the growing demand for energy-efficient solutions. Understanding the investment landscape and market entry options is essential for making informed decisions and maximizing opportunities in this sector.

One investment strategy is to establish strategic partnerships or collaborations with local manufacturers and suppliers. Partnering with established companies in the boiler economizer industry in Russia can provide several advantages, including access to local market knowledge, established distribution networks, and technical expertise. Collaborating with local partners can help navigate regulatory requirements, expedite market entry, and build strong relationships with key stakeholders.

Another investment strategy is to establish a manufacturing or assembly facility in Russia. Setting up a local production site offers advantages such as reduced production costs, streamlined supply chain management, and better control over product quality and customization. Manufacturing in Russia can also help meet local content requirements, which may be a consideration for government contracts or projects. Investing in local manufacturing demonstrates commitment to the Russian market and enhances competitiveness by offering localized products and faster delivery times.

Furthermore, investing in research and development (R&D) can be a strategic approach in the boiler economizer sector in Russia. By allocating resources to R&D efforts, companies can develop innovative and technologically advanced solutions tailored to the specific needs of the Russian market. This can involve enhancing heat transfer efficiency, exploring new materials, or integrating intelligent control systems. Investing in R&D not only strengthens product offerings but also positions companies as industry leaders and differentiates them from competitors.

Market entry opportunities in the boiler economizer sector in Russia include targeting specific industries or applications with high demand. Industries such as manufacturing, oil and gas, power generation, and district heating systems are key sectors where boiler economizers are in demand. Conducting market research to identify the specific needs and requirements of these industries can help tailor product offerings and marketing strategies accordingly. Additionally, exploring untapped regions or cities within Russia that are experiencing industrial growth presents entry opportunities for companies seeking to expand their market presence.

Overall, investment strategies in the boiler economizer sector in Russia involve establishing partnerships, considering local manufacturing, investing in R&D, and targeting high-demand industries or regions. The market entry opportunities in Russia are vast, driven by the increasing demand for energy-efficient solutions. By carefully assessing the market, identifying gaps, and aligning strategies with market needs, businesses can position themselves for success and capitalize on the growing opportunities in the boiler economizer sector in Russia.