Advancements in Technology for Large-Scale CFB Boilers

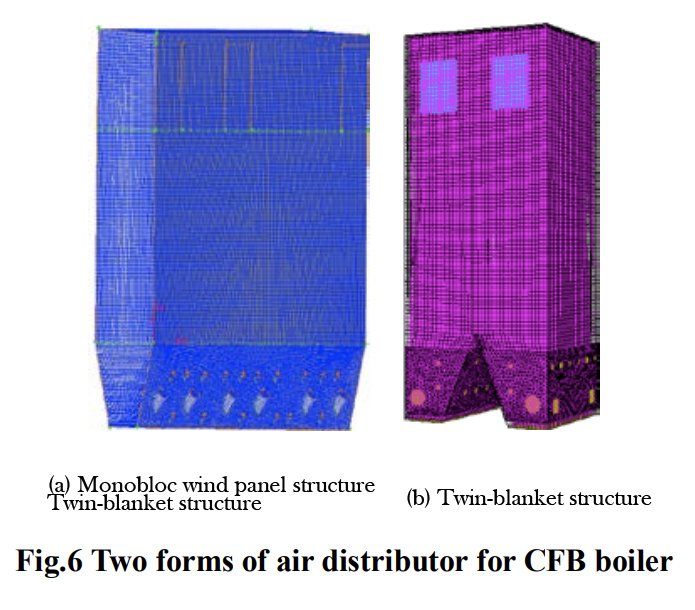

Single- and Double-Layer Air Plates in Circulating Fluidized Bed (CFB) Boilers As the scale of CFB boilers increases, so does the furnace size. This is exemplified in Table 1, which illustrates the cross-sectional area of the furnace in a 600 MW class CFB boiler reaching up to 418 m2. In the case of a furnace […]

Exploring Energy-Saving Technologies for Circulating Fluidized Bed Boilers (CFB Boilers)

Presently, the global landscape grapples with the intricacies of resource utilization and the escalating specter of resource depletion. Amidst the accelerating depletion of resources, the imperative to bolster resource efficiency has ascended as a linchpin in propelling production development. As societal and economic progress hurtles forward, the burgeoning requisites for enhanced quality of life and […]

Strategies for Mitigating Friction and Explosion Risks in CFB Boilers

The Circulating Fluidized Bed Boiler (CFB Boilers) has found extensive application in China since the 1990s and has garnered widespread adoption owing to its commendable environmental protection performance, streamlined system design, simplified combustion regulation, and robust adaptability to varying coal compositions. With an evolution spanning nearly three decades, this technology has established its prominence in […]

Enhancing the Operational Cycle of CFB Boiler through Technical Strategies

Within the framework of advancing the developmental standards of chemical enterprises, the operational demands for circulating fluidized bed boilers (CFB boiler) have attained a heightened significance. It is imperative for personnel to fortify their proficiency in the operation and administration of CFB boiler. This entails a comprehensive comprehension of the operational protocols governing these boilers, […]

Revamping Boiler Heating Surfaces in Waste Incinerators

Discover the path to heightened efficiency and durability in waste incinerators. Embark on a journey of transformation with advanced boiler heating surface upgrades. The waste-to-energy facility has a nominal garbage treatment capacity of 750 tons per day along with an additional 75 tons per day for drying municipal sludge. The rated evaporation capacity stands at […]

Analyzing Boiler Heating Surface Failures and Prevention in Power Plants

The boiler serves as the central component within a power plant’s infrastructure, playing a pivotal role in ensuring the operational safety of the entire facility. The stability and dependability of the boiler directly dictate the overall security of power plant operations. The heating surfaces of the boiler encompass four primary segments: the economizer, water-cooled wall, […]

Heating Surface Installation Quality Control for Bulk Boilers

The caliber of the installation process for the boiler heating surface significantly influences the operational safety of the boiler and the consistent provision of heat energy. Any inadequacies in the installation of the heating surface components can precipitate safety and operational mishaps during the boiler’s functioning, resulting in financial setbacks and disruptions in the enterprise’s […]

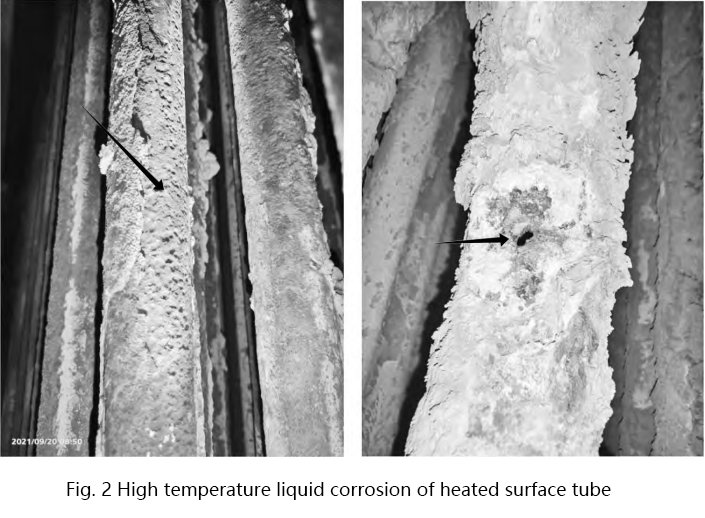

Analysis and Mitigation of High-Temperature Corrosion on the Heating Surface of Biomass Boilers

With the continuous depletion of fossil energy sources like coal, oil, and natural gas, coupled with the escalating environmental and climate issues stemming from their combustion, China’s green and sustainable “dual-carbon” development strategy underscores the importance of efficiently utilizing energy and seeking new alternative sources. Biomass energy, being renewable, low-pollution, and abundantly available, has garnered […]

Wear Analysis of Boiler Heating Surfaces in a Circulating Fluidized Bed Furnace

Boiler Overview: The circulating fluidized bed boiler is known for its exceptional fuel adaptability, enabling efficient utilization of low-quality fuels during combustion. Moreover, its low combustion temperature offers advantages such as reduced nitrogen oxide emissions. Consequently, the domestic circulating fluidized bed boiler has witnessed rapid development. However, the unique characteristics of the fuel and combustion […]

Study of High-Temperature Corrosion on the Boiler Heating Surface in Waste Incineration

Unraveling the Enigma: Understanding High-Temperature Corrosion on Boiler Heating Surface With a focus on advocating green practices, environmental protection, and adopting a low-carbon lifestyle, waste incineration power generation has gradually become the mainstream method for domestic waste treatment, characterized by its attributes of “harmlessness, resourcefulness, and reduction.” As China’s domestic waste production continues to escalate, […]

Research on Boiler Heating Surface Installation Technology of 1000MW Unit

Large-capacity, high-parameter units have gained widespread acceptance as mainstream generating units owing to their notable advantages, such as low coal consumption, high operating efficiency, compact footprint, and minimal pollutant emissions. During the construction of these large generating units, special attention must be given to the installation of the boiler and its ancillary equipment, with particular […]

Advancements in Waste Incinerator Boiler Heating Surface Protection

To achieve a low-carbon, environmentally sustainable society, the adoption of renewable fuels like biomass and waste presents promising alternatives to coal and oil for power generation. However, the corrosive nature of the heating surface environment in plant boilers utilizing these fuels surpasses that of fossil fuels. Particularly in biomass and waste incinerators, the water-cooled walls […]