Are you ready to unlock the secrets behind HRSG boilers and revolutionize your boiler operations? We have meticulously crafted this resource to provide you with a roadmap for success.

The Basics of HRSG Boilers: Understanding the Technology

What is HRSG boilers?

HRSG boilers (Heat Recovery Steam Generators) represent a remarkable advancement in boiler technology. Designed to harness waste heat from various sources, such as gas turbines, engines, or industrial processes, HRSG (Heat Recovery Steam Generator) boilers are capable of converting this heat into usable steam, thus maximizing energy efficiency and reducing overall fuel consumption.

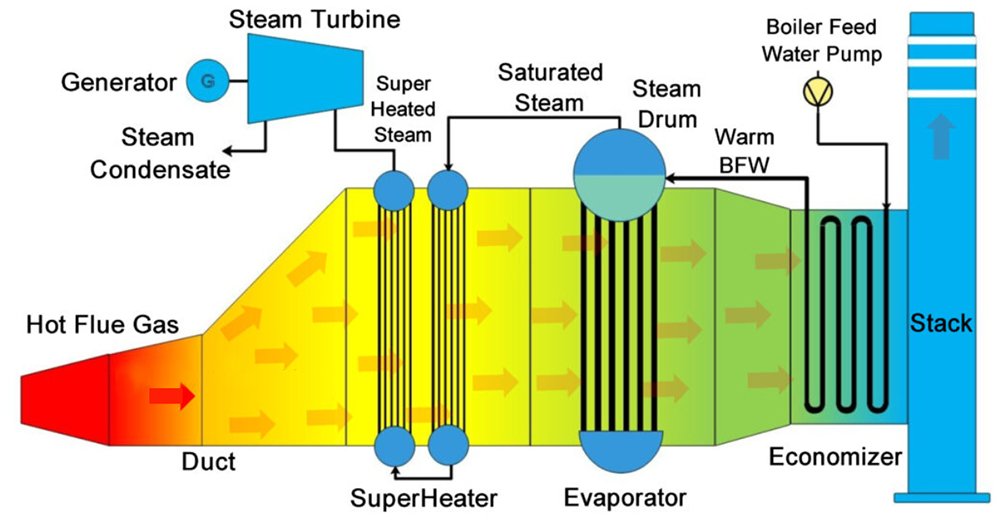

At the heart of an HRSG boiler lies the heat recovery system. This system consists of various heat exchangers that capture the waste heat and transfer it to the water circulating within the boiler. As the hot gases pass through the heat exchangers, the water within the tubes absorbs the thermal energy, transforming it into steam. This steam can then be utilized for various purposes, including power generation or heating applications.

One key component of an HRSG (Heat Recovery Steam Generator) boiler is the economizer. Located at the boiler’s inlet, the economizer preheats the water using the waste heat from the flue gases. By doing so, it significantly reduces the energy required to bring the water to its boiling point, resulting in improved efficiency and reduced fuel consumption.

Another crucial element of the HRSG boiler is the evaporator section. Here, the water absorbs heat from the hot gases and undergoes phase change, transforming into steam. The steam generated in the evaporator section is then collected and further processed for its intended application.

Furthermore, HRSG boilers often incorporate superheaters and reheaters to enhance the steam quality. Superheaters raise the steam temperature to higher levels, increasing its energy content and enabling more efficient power generation. Reheaters, on the other hand, are utilized in multi-stage steam turbines, where the steam is reheated before entering subsequent turbine stages to maintain its temperature and maximize turbine efficiency.

Overall, HRSG boilers offer several advantages. Firstly, they allow for the recovery of otherwise wasted heat, leading to substantial energy savings and reduced environmental impact. Secondly, their modular design allows for flexibility in installation and adaptation to varying operational needs. Additionally, HRSG boilers can be integrated into combined cycle power plants, where they complement the gas or steam turbines, resulting in enhanced overall plant efficiency.

Understanding the basics of HRSG (Heat Recovery Steam Generator) boiler technology is essential for high-performance boiler buyers. By grasping the fundamental principles behind the heat recovery process and the key components that make up an HRSG boiler, buyers can make informed decisions and harness the true potential of this groundbreaking technology. In the following sections, we will delve deeper into the features, benefits, and considerations associated with HRSG (Heat Recovery Steam Generator) boilers for high-performance applications.

Key Features and Components of HRSG Boilers

HRSG (Heat Recovery Steam Generator) boilers are renowned for their advanced features and intricate components that contribute to their exceptional performance in high-performance applications. Understanding these key features and components is crucial for boiler buyers looking to invest in HRSG technology. Let’s explore them in detail.

- Heat Exchangers: The heart of an HRSG boiler lies in its heat exchangers. These devices are responsible for transferring heat from the hot exhaust gases to the water, facilitating the conversion of heat energy into steam. HRSG boilers typically employ multiple heat exchangers, including the economizer, evaporator, and superheater/reheater sections.

- Economizer: The economizer is positioned at the inlet of the HRSG boiler and serves to preheat the feedwater by utilizing the waste heat from the flue gases. By recovering this heat, the economizer significantly enhances energy efficiency by reducing the amount of fuel required to reach the desired steam temperature.

- Evaporator: The evaporator section of an HRSG boiler is where the bulk of heat transfer occurs. In this section, water absorbs heat from the hot exhaust gases, undergoing a phase change from liquid to steam. The evaporator is typically comprised of a series of tubes through which the water flows, while the hot gases pass over them, facilitating the heat transfer process.

- Superheater and Reheater: HRSG boilers often incorporate superheaters and reheaters to optimize steam quality. The superheater section raises the temperature of the steam to higher levels after it leaves the evaporator, increasing its energy content and ensuring its suitability for specific applications. Reheaters are utilized in multi-stage steam turbines, where the steam is reheated between stages to maintain its temperature and maximize turbine efficiency.

- Control Systems: HRSG boilers feature sophisticated control systems that monitor and regulate various parameters, ensuring optimal performance and safety. These systems manage functions such as combustion control, feedwater temperature control, and steam pressure control, among others, to maintain efficient and stable operation.

- Modular Design: HRSG boilers are often designed with modularity in mind, allowing for flexible installation and adaptation to varying operational needs. The modular approach enables easier maintenance, repairs, and future expansions, making HRSG boilers a versatile and scalable choice for high-performance applications.

- Materials and Construction: HRSG boilers are constructed using high-quality materials capable of withstanding high temperatures, pressure differentials, and corrosive environments. The selection of materials ensures long-term reliability and durability, making HRSG (Heat Recovery Steam Generator) boilers suitable for demanding industrial settings.

- Integration Capabilities: HRSG boilers are designed to seamlessly integrate with other components in a power generation system, such as gas or steam turbines. This integration enables combined cycle power plants, where the waste heat from the turbines is utilized by the HRSG boiler to generate additional steam and power, maximizing overall plant efficiency.

Understanding the key features and components of HRSG (Heat Recovery Steam Generator) boilers empowers high-performance boiler buyers to make informed decisions. These features, such as the various heat exchangers, control systems, modular design, and integration capabilities, contribute to the efficiency, reliability, and adaptability of HRSG boilers in demanding operational environments. In the subsequent sections, we will explore how HRSG boilers improve energy efficiency, address sizing and capacity considerations, and delve into real-world case studies to showcase their successful implementations in high-performance applications.

Exploring the Different Types of HRSG Boilers and Their Advantages

Exploring the Different Types of HRSG Boilers and Their Advantages

HRSG boilers come in various types, each designed to cater to specific requirements and operational conditions. Understanding the different types of HRSG (Heat Recovery Steam Generator) boilers and their advantages is essential for high-performance boiler buyers seeking the most suitable solution for their applications. Let’s explore these types and delve into their unique benefits.

Horizontal HRSG Boilers:

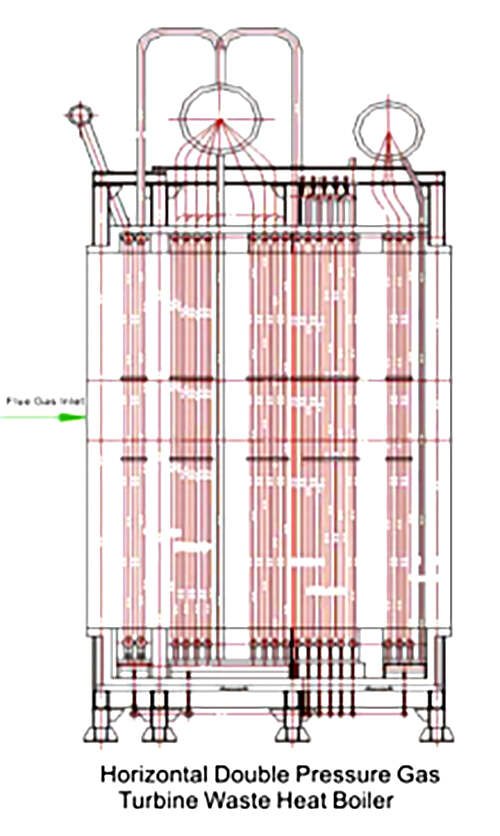

Horizontal HRSG (Heat Recovery Steam Generator) boilers are characterized by their horizontal orientation and are commonly used in applications where space is limited. These compact boilers offer a smaller footprint, making them ideal for installations where vertical space is constrained. They are often employed in industrial processes, combined heat and power (CHP) plants, and cogeneration systems.

Advantages:

- Space-efficient design, suitable for installations with limited vertical space.

- Easy accessibility for maintenance and inspection.

- Simplified integration into existing plant layouts.

Vertical HRSG Boilers:

Vertical HRSG (Heat Recovery Steam Generator) boilers, as the name suggests, feature a vertical orientation. These boilers are typically utilized in large-scale power generation facilities, where vertical space is available. Vertical HRSG (Heat Recovery Steam Generator) boilers offer high heat transfer efficiency and can handle large capacity requirements.

Advantages:

- High heat transfer efficiency due to the vertical design.

- Suitable for high-capacity applications.

- Can be integrated into large power generation plants.

Once-Through HRSG Boilers:

Once-through HRSG (Heat Recovery Steam Generator) boilers operate on the principle of continuous water flow without recirculation. In this type of boiler, water passes through the heat exchanger tubes only once, absorbing heat and rapidly producing steam. Once-through HRSG (Heat Recovery Steam Generator) boilers are known for their fast startup and response times, making them suitable for applications where quick load changes are common.

Advantages:

- Fast startup and response times.

- Well-suited for applications with frequent load fluctuations.

- High efficiency due to reduced water volume and lower pressure losses.

Modular HRSG Boilers:

Modular HRSG boilers are designed with a modular construction approach, where multiple boiler modules are combined to form a complete system. Each module operates independently, allowing for easy maintenance, scalability, and redundancy. Modular HRSG (Heat Recovery Steam Generator) boilers are often preferred for their flexibility, adaptability, and simplified installation.

Advantages:

- Flexible and scalable design, accommodating changing operational needs.

- Easier maintenance and repairs due to the independent operation of modules.

- Enhanced redundancy, ensuring continued operation even in the event of a module failure.

Supplementary Fired HRSG Boilers:

Supplementary fired HRSG (Heat Recovery Steam Generator) boilers incorporate an additional burner system to supplement the heat recovered from exhaust gases. This burner system allows for additional heat input, increasing the steam production capacity and offering greater operational flexibility. Supplementary fired HRSG boilers are commonly used in applications where higher steam demand or varying load conditions exist.

Advantages:

- Increased steam production capacity and flexibility.

- Ability to meet varying steam demand and load fluctuations.

- Enhanced control over steam generation and temperature.

Understanding the different types of HRSG (Heat Recovery Steam Generator) boilers and their advantages enables high-performance boiler buyers to choose the most suitable option for their specific needs. Whether it’s a horizontal or vertical design, once-through or modular configuration, or the incorporation of supplementary firing, each type offers unique benefits that cater to different operational requirements. In the subsequent sections, we will delve deeper into sizing and capacity considerations, as well as provide real-world case studies showcasing the successful implementation of HRSG boilers in high-performance applications.

HRSG Boiler Sizing and Capacity Considerations for High-Performance Needs

When it comes to HRSG boilers for high-performance applications, proper sizing and capacity considerations are of utmost importance. The sizing process involves determining the appropriate dimensions and specifications of the HRSG (Heat Recovery Steam Generator) boiler to meet the steam generation demands of the specific application. Let’s explore the key factors and considerations involved in HRSG boiler sizing for high-performance needs.

| Consideration | Description |

|---|---|

| Steam Demand | Determine required steam flow rate, pressure, and temperature for the application. |

| Heat Source | Identify the heat source (gas turbines, engines, etc.) and understand its characteristics, such as exhaust gas temperature and flow rate. |

| Efficiency and Heat Recovery | Consider the HRSG boiler’s efficiency in heat recovery, which impacts its size and overall performance. |

| Pressure and Temperature | Determine the desired steam pressure and temperature for the application. |

| Load Variation and Turndown Ratio | Assess the anticipated load fluctuations and ensure the HRSG boiler has a suitable turndown ratio for efficient operation. |

| Future Expansion | Consider potential future expansion and increased steam demand, ensuring the HRSG boiler can accommodate growth without significant modifications. |

By carefully considering the steam demand, heat source characteristics, efficiency, pressure and temperature requirements, load variation, and future expansion, high-performance boiler buyers can determine the appropriate sizing and capacity for their HRSG (Heat Recovery Steam Generator) boilers. Engaging with experienced engineers and consultants specializing in HRSG technology can provide valuable insights and assistance in making accurate sizing calculations. In the subsequent sections, we will explore real-world case studies showcasing successful HRSG boiler implementations in high-performance applications, further highlighting the significance of proper sizing and capacity considerations.

Integration of HRSG Boilers with Combined Cycle Power Plants

The integration of HRSG (Heat Recovery Steam Generator) boilers with combined cycle power plants is a highly efficient and widely adopted approach in the power generation industry. Combined cycle power plants combine the benefits of gas or steam turbines with HRSG technology, maximizing energy conversion and overall plant efficiency. Let’s delve into the details of how HRSG boilers seamlessly integrate with combined cycle power plants.

In a combined cycle power plant, the HRSG (Heat Recovery Steam Generator) boiler plays a crucial role in harnessing the waste heat generated by the gas or steam turbine. Typically, the exhaust gases from the turbine contain a significant amount of thermal energy, which can be captured and utilized by the HRSG boiler to produce steam. This integration allows for the efficient utilization of fuel and enhances the overall plant performance.

The HRSG boiler is positioned downstream of the gas or steam turbine, receiving the exhaust gases as a heat source. These gases pass through the HRSG’s heat exchanger sections, such as the economizer, evaporator, superheater, and reheater, where heat is transferred to the water circulating within the HRSG boiler. The water absorbs the heat, producing steam that can be utilized for various purposes, such as driving a steam turbine for additional power generation or providing process heat in industrial applications.

One of the key advantages of integrating HRSG boilers with combined cycle power plants is the utilization of otherwise wasted heat. The HRSG captures the waste heat from the turbine’s exhaust gases, significantly increasing the overall energy conversion efficiency. This integration allows for a substantial reduction in fuel consumption and greenhouse gas emissions compared to conventional power generation systems.

Furthermore, the integration of HRSG (Heat Recovery Steam Generator) boilers with combined cycle power plants enhances the plant’s flexibility and load-following capabilities. HRSG boilers can quickly respond to fluctuations in power demand by adjusting the steam production, ensuring efficient operation across a wide range of load conditions. This flexibility is particularly valuable in applications where grid stability and demand response are crucial.

The modular design of HRSG (Heat Recovery Steam Generator) boilers further facilitates their integration with combined cycle power plants. Modular HRSG units can be added or removed based on the power plant’s capacity requirements, allowing for easy expansion or modification as needed. This modularity also simplifies maintenance and repairs since individual modules can be isolated for service without affecting the entire plant operation.

The integration of HRSG boilers with combined cycle power plants has become a preferred choice for many energy producers due to its numerous benefits. The efficient utilization of waste heat, enhanced overall plant efficiency, flexibility in load-following, and scalability make combined cycle power plants with HRSG boilers an economically and environmentally viable solution for high-performance power generation.

In the subsequent sections, we will explore real-world examples and case studies showcasing successful implementations of HRSG (Heat Recovery Steam Generator) boilers in combined cycle power plants, further highlighting the advantages and performance of this integrated approach.

Case Studies: Success Stories of High-Performance HRSG Boiler Implementations

A power plant in Southeast Asia: Power Plant integrated HRSG boilers into their combined cycle system, harnessing the waste heat from their gas turbines. The implementation led to a remarkable 30% improvement in overall plant efficiency, enabling them to generate more electricity without consuming additional fuel. This not only enhanced their profitability but also reduced their carbon footprint, contributing to a greener energy production process.

FAQ

Q1: What does HRSG stand for?

A1: HRSG stands for Heat Recovery Steam Generator.

Q2: What is the purpose of an HRSG boiler?

A2: The purpose of an HRSG (Heat Recovery Steam Generator) boiler is to recover waste heat from exhaust gases and convert it into steam, which can be used for various applications, such as power generation or industrial processes.

Q3: How does an HRSG boiler work?

A3: An HRSG (Heat Recovery Steam Generator) boiler works by utilizing the waste heat from gas or steam turbines. The hot exhaust gases pass through heat exchanger sections, transferring their heat to water circulating within the HRSG boiler. This heat transfer converts water into steam, which can be used for power generation or other purposes.

Q4: What are the advantages of HRSG boilers?

A4: Some advantages of HRSG boilers include higher energy efficiency, reduced fuel consumption, lower emissions, flexibility in load-following, and the ability to integrate with other power generation systems, such as combined cycle plants.

Q5: What are the key components of an HRSG boiler?

A5: The key components of an HRSG boiler include heat exchangers (economizer, evaporator, superheater, and reheater), control systems, supplementary firing systems (in some cases), and various auxiliary equipment for steam and water treatment.

Q6: What are the different types of HRSG boilers?

A6: HRSG boilers can be classified into different types, including horizontal and vertical configurations, once-through designs, modular units, and supplementary fired boilers. Each type offers unique advantages and is suitable for specific applications.

Q7: How is HRSG boiler sizing determined?

A7: HRSG boiler sizing is determined based on factors such as steam demand, heat source characteristics, efficiency requirements, pressure and temperature considerations, load variation, and future expansion needs. Accurate sizing calculations are crucial to ensure the HRSG boiler meets the specific requirements of the application.

Q8: Can HRSG boilers be integrated with other power generation systems?

A8: Yes, HRSG boilers are commonly integrated with other power generation systems, such as gas or steam turbines, in combined cycle plants. This integration allows for the efficient utilization of waste heat and enhances overall plant efficiency.

Q9: What are the maintenance requirements for HRSG boilers?

A9: Regular maintenance is essential for optimal performance and longevity of HRSG boilers. Maintenance tasks may include cleaning heat exchanger surfaces, inspecting and repairing insulation, monitoring control systems, and performing water and steam quality checks.

Q10: Are HRSG boilers suitable for all industries?

A10: HRSG boilers find applications in a wide range of industries, including power generation, cogeneration, oil and gas, chemical, and manufacturing. They are particularly beneficial in high-performance applications where energy efficiency and waste heat recovery are crucial.

Don’t Miss Out on the Advantages of HRSG Boilers. Take the Next Step and Request a Quote Now!