If you’re in the market for a boiler that combines exceptional performance with a host of impressive advantages, then you’ve come to the right place. We will take you on a journey through the remarkable advantages of CFB boilers and shed light on why they are revolutionizing the energy industry.

Join us as we uncover the key benefits that make CFB boilers a game changer in the world of heating and power generation. From their unparalleled fuel flexibility to their superior combustion efficiency, reduced emissions, enhanced operational flexibility, and significant cost savings, we’ll leave no stone unturned.

High Combustion Efficiency: Exploring the Superiority of CFB Boilers

When it comes to efficient and sustainable energy solutions, circulating fluidized bed (CFB) boilers have gained significant recognition in the industry. CFB boilers are known for their ability to provide high combustion efficiency, surpassing that of traditional boilers. In this article, we will delve into the key factors that contribute to the enhanced combustion efficiency of CFB boilers and why they outperform their conventional counterparts.

- Fluidized Bed Combustion:

At the core of CFB boilers lies the concept of fluidized bed combustion. Unlike traditional boilers that rely on a fixed bed, CFB boilers utilize a fluidized bed of solid particles suspended in a flow of air or gas. This unique feature allows for efficient and complete combustion of fuels.

- Enhanced Fuel Mixing:

One of the primary reasons for the high combustion efficiency of CFB boilers is their superior fuel mixing capabilities. The fluidized bed of solid particles facilitates the thorough mixing of fuel and air, ensuring optimal combustion conditions. This uniform mixing minimizes the presence of hotspots and coldspots, leading to more efficient fuel utilization and reduced emissions. - Longer Residence Time:

CFB boilers provide a longer residence time for fuel particles within the combustion chamber. As the particles circulate in the fluidized bed, they spend more time in the combustion zone, resulting in improved combustion efficiency. This extended residence time allows for better fuel burnout, reducing the formation of unburned carbon and other pollutants. - Effective Heat Transfer:

Efficient heat transfer is another critical aspect contributing to the high combustion efficiency of CFB boilers. The circulating fluidized bed facilitates the transfer of heat from the combustion zone to the boiler tubes, optimizing the energy conversion process. This enhanced heat transfer capability leads to improved thermal efficiency and overall system performance. - Fuel Flexibility:

CFB boilers exhibit exceptional fuel flexibility, enabling the combustion of a wide range of fuels, including biomass, coal, and various waste materials. The ability to accommodate diverse fuel types enhances the efficiency of energy production. Additionally, CFB boilers can utilize low-quality fuels that would be challenging for traditional boilers, thereby reducing waste and improving the cost-effectiveness of energy generation.

Circulating fluidized bed (CFB) boilers excel in terms of combustion efficiency, outperforming traditional boilers in several key areas. The unique fluidized bed combustion technology, along with superior fuel mixing, longer residence time, effective heat transfer, and fuel flexibility, contribute to their high combustion efficiency. By harnessing the advantages of CFB boilers, industries can achieve optimal energy utilization, reduced emissions, and increased sustainability. The continued advancements in CFB boiler technology further solidify their position as a reliable and efficient solution for modern energy needs.

Fuel Flexibility: Unlocking the Power of CFB Boilers for Diverse Fuel Types

In the quest for sustainable energy solutions, circulating fluidized bed (CFB) boilers have emerged as a versatile and efficient option. One of the key advantages of CFB boilers lies in their exceptional fuel flexibility, allowing them to accommodate a wide range of fuel types. In this article, we will explore how CFB boilers harness this advantage, specifically by accommodating biomass and low-quality coal, and how it contributes to their significance in the energy industry.

Embracing Biomass:

CFB boilers are renowned for their ability to efficiently burn biomass, making them a crucial player in the transition towards renewable energy sources. Biomass, such as wood pellets, agricultural residues, and energy crops, offers a sustainable alternative to fossil fuels. CFB boilers excel in utilizing biomass due to their fluidized bed combustion technology, which allows for the complete combustion of various biomass feedstocks. This results in efficient energy conversion while minimizing environmental impacts, such as reduced carbon dioxide emissions.

Leveraging Low-Quality Coal:

Another remarkable aspect of CFB boilers is their capacity to handle low-quality coal, which may have a high ash content, low calorific value, or other undesirable properties. Conventional boilers often struggle with such fuels, leading to inefficient combustion and increased emissions. However, CFB boilers, with their fluidized bed design, can efficiently burn low-quality coal, enabling its utilization and preventing it from becoming a wasted resource. This flexibility makes CFB boilers suitable for regions with abundant but challenging coal resources, thus promoting energy security and reducing dependence on higher-grade coals.

Adapting to Co-Firing:

CFB boilers offer the unique advantage of co-firing, which involves the simultaneous combustion of multiple fuels. This capability allows for the blending of different fuel types, such as biomass and coal, within the same boiler system. Co-firing enhances fuel flexibility by providing opportunities to optimize fuel selection based on availability, cost, and environmental considerations. It also facilitates the gradual transition from fossil fuels to renewable alternatives by gradually increasing the proportion of biomass in the fuel mix.

Synergistic Benefits of Fuel Flexibility

The fuel flexibility of CFB boilers brings forth numerous benefits. Firstly, it ensures a stable energy supply by reducing reliance on a single fuel source. This is particularly valuable in regions where fuel availability or quality may vary. Secondly, fuel flexibility contributes to cost optimization, as it enables the use of locally available and potentially lower-cost fuel options. Moreover, the ability to accommodate diverse fuels promotes the utilization of waste materials, such as agricultural residues or industrial byproducts, transforming them into valuable energy resources.

The exceptional fuel flexibility of circulating fluidized bed (CFB) boilers makes them an indispensable tool in the energy landscape. By accommodating a wide range of fuel types, including biomass and low-quality coal, CFB boilers unlock opportunities for sustainable energy generation, reduced emissions, and enhanced energy security. The ability to co-fire fuels further amplifies their adaptability and paves the way for a gradual transition to renewable energy sources. As the world seeks diverse and sustainable energy solutions, the fuel flexibility of CFB boilers positions them at the forefront of this transformation, empowering industries and communities to meet their energy needs in an efficient and environmentally responsible manner.

Circulating fluidized bed (CFB) boilers offer a significant advantage in reducing emissions, including sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. In this article, we explore how CFB boilers contribute to lower emissions, promoting environmental stewardship and sustainability.

CFB Boilers: Reducing Emissions for a Cleaner Future

Circulating fluidized bed (CFB) boilers offer a significant advantage in reducing emissions, including sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. In this article, we explore how CFB boilers contribute to lower emissions, promoting environmental stewardship and sustainability.

Efficient Combustion: CFB boilers achieve high combustion efficiency, minimizing the formation of SO2, NOx, and particulate matter. Thorough fuel and air mixing ensures complete combustion, reducing emissions.

SO2 Capture: Limestone injection in CFB boilers captures a significant portion of SO2 emissions. The injected sorbent reacts with SO2, reducing its environmental impact and supporting cleaner air quality.

Low NOx Formation: CFB boilers operate at lower temperatures, reducing thermal NOx formation. Advanced combustion control techniques further minimize NOx emissions, enhancing air quality standards.

Particulate Matter Control: CFB boilers effectively capture and retain particulate matter. Advanced control technologies, such as electrostatic precipitators, enhance emission control and maintain high air quality.

We’ve unraveled the extraordinary advantages that make circulating fluidized bed (CFB) boilers a force to be reckoned with. Their unparalleled fuel flexibility, superior combustion efficiency, reduced emissions, enhanced operational flexibility, and significant cost savings set them apart from conventional boilers.

So, if you’re seeking a boiler that offers a winning combination of performance, environmental friendliness, and economic viability, look no further than CFB technology. Embrace the power of CFB boilers and unlock a future of endless possibilities for your heating and power needs.

CFB boilers play a vital role in reducing emissions, supporting environmental compliance, and driving sustainability efforts. Their efficient combustion, SO2 capture, low NOx formation, and effective particulate matter control contribute to a cleaner and greener future.

DHB’S CFB boilers (circulating fluidized bed boilers)

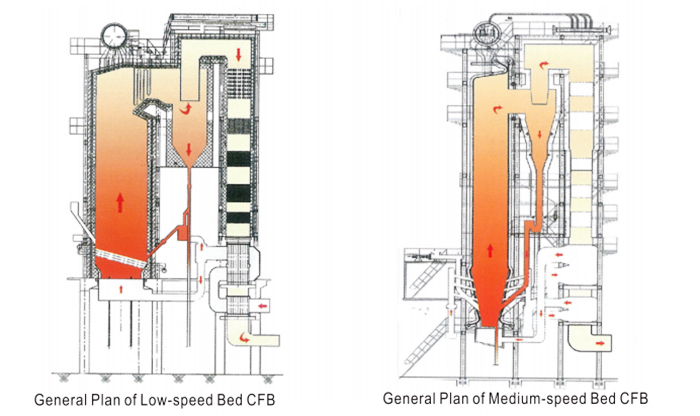

As a new mature high-efficiency and low-pollution clean coal technology, circulating fluidized bed combustion (CFBC) technology has many advantages that other com-bust ion methods do not have.

Circulating fluidized bed combustion is low-temperature combustion, so the NOx emission is much lower than that of pulverized coal furnace, only 100ppm.CFBC can de-sulfurize directly during the combustion process, and the desulfurization efficiency is high. The technology and equipment are simple and economic, and the costs of its initial investment and operation are much lower than those of dry pulverized coal furnace and flue gas desulfurization (PC+FCD). The discharged ash residue has good activity and is easy to be comprehensive utilized without secondary ash residue pollution. The load adjust-ment range is large, and the low load can be reduced to about 30% of the full load.

Technical advantages

High temperature cyclone separator

High efficiency, wear resistance, separation efficiency ≥ 98%, effectively improve the combustion efficiency of the boiler thermal efficiency

Large furnace design

Large furnace, low velocity design; the application of wearproof tube technology, reducing erosive abrasion.

Extend the residence time of coal particles in the furnace so that the coal can be fully burned.

Bell jar type hood

Adopt bell type hood to distribute air averagely and avoid fuel reverse to wind chamber.

Low bed pressure operation

By particle optimization, the operating bed pressure can be decreased to 3500Pa, which effectively saves operating costs and greatly reduces the oxynitride generated.

What can DHB’s circulating fluidized bed (CFB) boilers bring to you?

Wide fuel adaptability

Applicable to a wide range of fuels including coal, gangue, waste, sludge, etc.

Customized solutions save money and time.

Save you money and time with custom designed and engineered feeding system, slag discharge system, flue gas treatment system and boiler house layout plans

Higher thermal efficiency

Thermal efficiency at least 5% higher than normal systems, annualfuel cost savings for each 29MW boiler as high as $150,000

High level of automation

Easy maintenance, high level of automation that requires less involvement of operational and maintenance personnel.

Advanced control system

Ensure stable operation while saving investment cost for you with a reasonable selection.

35t/H CFB Boilers

| Name | Unit | Spec. | |

| Model | DH-35/3.82-M | DH-35/5.3-M | |

| Rated Evaporation Capacity | t/h | 35 | 35 |

| Maximum Continuous Evaporation | t/h | 35 | 35 |

| Rated Steam Pressure | MPa | 3.82 | 5.3 |

| Rated Steam Temperature | ℃ | 450 | 450 |

| Feed Water Temperature | ℃ | 150 | 150 |

| Adaptive Fuels | Anthracite,lean coal,bituminous coal,lignite,petroleum coke,etc. | ||

| Water side resistance of boiler body | MPa | 0.3 | 0.5 |

| Steam side resistance of the boiler body | MPa | 0.4 | 0.4 |

| Primary wind-side resistance | Pa | 12000 | 12000 |

| Secondary wind-side resistance | Pa | 8000 | 8000 |

| Induced air-side resistance | Pa | 3600 | 3600 |

| Feed return device resistance | Pa | 18000 | 18000 |

| Hearth height | m | 22 | 22 |

| Hearth section | ㎡ | 9.6 | |

| Air distribution plate section | ㎡ | 5.7 | |

| Residence time of flue gas inside the hearth | Sec | >5 | |

| Number of separators | Set | 2 | |

| Separator Type | Membrane-type wall steam cooling (or water cooling) or steel plate heat-insulation type, volute type. | ||

| Inner diameter of separator | m | 1.9 | |

| Separator separation efficiency | % | >99.5 | |

| Number of coal feeders | Set | 2 | |

| Superheater attemperation mode | By spraying the self-produced condensed water or feed water | ||

| Carbon content in boiler ashes (when burning the bituminous coal) | % | ﹤6 | |

| Temperature of the preheated air | ℃ | 141 | |

| Temperature of the exhaust flue gas | ℃ | 144 | |

| Elevation of the operating level | m | 7 | |

| Elevation of the boiler roof plate | m | 33 | |

75t/H CFB Boilers

| Name | Unit | Spec. | ||

| Model | DH-75/3.82-M | DH-75/3.82-M | DH-75/3.82-M | |

| Rated Evaporation Capacity | t/h | 75 | 75 | 75 |

| Maximum Continuous Evaporation | t/h | 85 | 85 | 85 |

| Rated Steam Pressure | Mpa | 3.82 | 5.3 | 9.8 |

| Rated Steam Temperature | ℃ | 450 | 485 | 540 |

| Feed Water Temperature | ℃ | 150 | 150 | 215 |

| Adaptive Fuels | Anthracite, lean coal, bituminous coal, lignite, petroleum coke,chain ashes, etc. | |||

| Water side resistance of boiler body | Mpa | 0.3 | 0.3 | 0.3 |

| Steam side resistance of the boiler body | Mpa | 0.4 | 0.4 | 1 |

| Primary wind-side resistance | Pa | 12500 | 23500 | 12500 |

| Secondary wind-side resistance | Pa | 8500 | 8500 | 8500 |

| Induced air-side resistance | Pa | 3600 | 3600 | 3600 |

| Feed return device resistance | Pa | 40000 | 40000 | 40000 |

| Hearth height | m | 26.2 | 26.2 | 26.2 |

| Hearth section | m² | 21 | 21 | 21 |

| Air distribution plate section | m² | 9.5 | 9.5 | 9.5 |

| Residence time of flue gas inside the hearth | Sec | >5.5 | ||

| Number of separators | Set | 2 | ||

| Separator Type | Membrane-type wall steam cooling (or water cooling) or steel plate heat-insulation type, volute type. | |||

| Inner diameter of separator | m | 3 | ||

| Separator separation efficiency | % | 99.5 | ||

| Number of coal feeders | Set | 2 | ||

| Superheater attemperation mode | By spraying the self-produced condensed water or feed water Feed water spraying | |||

| Carbon content in boiler ashes (when burning the bituminous coal) | % | >6 | ||

| Temperature of the preheated air | ℃ | 150 | ||

| Temperature of the exhaust flue | ℃ | 145 5 | ||

| Elevation of the operating level | m | 7 | ||

| Elevation of the boiler roof palte | m | 37 | ||

130t/H CFB Boilers

| Name | Unit | Spec. | ||

| Model | DH-130/3.82-M | DH-130/3.82-M | DH-130/3.82-M | |

| Rated Evaporation Capacity | t/h | 130 | 130 | 130 |

| Maximum Continuous Evaporation | t/h | 150 | 150 | 150 |

| Rated Steam Pressure | Mpa | 3.82 | 5.3 | 5.3 |

| Rated Steam Temperature | ℃ | 450 | 485 | 485 |

| Feed Water Temperature | ℃ | 150 | 150 | 150 |

| Adaptive Fuels | Anthracite, lean coal, bituminous coal, lignite, petroleum coke,chain ashes, etc. | |||

| Water side resistance of boiler body | Mpa | 0.3 | 0.3 | 0.3 |

| Steam side resistance of the boiler body | Mpa | 0.75 | 0.7 | 0.7 |

| Primary wind-side resistance | Pa | 13500 | 13500 | 13500 |

| Secondary wind-side resistance | Pa | 9000 | 9000 | 9000 |

| Induced air-side resistance | Pa | 3800 | 3800 | 3800 |

| Feed return device resistance | Pa | 48000 | 48000 | 48000 |

| Hearth height | m | 29.9 | 29.9 | 29.9 |

| Hearth section | m² | 39.2 | 39.2 | 39.2 |

| Air distribution plate section | m² | 19.1 | 19.1 | 19.1 |

| Residence time of flue gas inside the hearth | Sec | <5.5~6 | ||

| Number of separators | Set | 2 | ||

| Separator Type | Membrane-type wall steam cooling (or water cooling) or steel plate heat-insulation type, volute type. | |||

| Inner diameter of separator | m | 3.82 | ||

| Separator separation efficiency | % | 99.5 | ||

| Number of coal feeders | Set | 3 | ||

| Superheater attemperation mode | By spraying the self-produced condensed water or feed water Feed water spraying | |||

| Carbon content in boiler ashes (when burning the bituminous coal) | % | >6 | ||

| Temperature of the preheated air | ℃ | 145 5 | ||

| Elevation of the operating level | m | 8 | ||

| Elevation of the boiler roof palte | m | 43.6 | 44.6 | 43.2 |

| Boiler column spacing | m | 17.6 10 | 17.55 10 | 17.55 10 |

Stay tuned as we delve deeper into each advantage, providing you with invaluable insights to help you make informed decisions. The world of CFB boilers awaits—let’s embark on this transformative journey together.

In conclusion, circulating fluidized bed (CFB) boilers represent a remarkable advancement in energy technology, offering numerous advantages for industries and communities alike. From their high combustion efficiency and fuel flexibility to the significant reduction in emissions, CFB boilers pave the way for a sustainable and cleaner future. By embracing CFB technology, we can achieve optimal energy utilization, minimize environmental impact, and contribute to a greener planet. Let’s harness the power of CFB boilers and forge a path towards a more efficient, sustainable, and environmentally conscious tomorrow. Join the movement today and be part of the energy revolution that will shape our future for generations to come.

Don’t miss out on the game-changing benefits of CFB boilers! Discover how they revolutionize energy generation. Explore now and unlock a sustainable tomorrow!