The circulating fluidized bed boiler is known for its high combustion efficiency, wide fuel adaptability, low NOx emissions, and high comprehensive utilization of ash residues[1-2], meeting the requirements of an efficient, clean, green, and sustainable development model. However, a high failure rate and short operating cycles are significant challenges for circulating fluidized bed boilers. The normal operation of the return material system is crucial for the stable and economical operation of the unit. As a key component in the material circulation system of circulating fluidized bed boilers, its primary function is to return the unburned fuel separated by the cyclone separator back to the furnace for further combustion[3].

Su Jinshuozhou Coal Gangue Power Generation Co., Ltd. (referred to as Su Jinshuo Power) is home to the world’s first 660 MW circulating fluidized bed unit. Since the operation of the unit, abnormal conditions in the return material system have consistently posed a challenge to the stable operation of the boiler. This article conducts an in-depth analysis, focusing on several common abnormal phenomena encountered in the operation of circulating fluidized bed boilers.

1. Structure and Working Principle of the Circulating Fluidized Bed Boiler Return Material System

The circulating fluidized bed boiler in question employs a CFB supercritical UP-type direct-flow boiler designed and manufactured by Dongfang Boiler Factory, with the boiler model being DG 2162/25.4-II1. The furnace is of a separate rectangular single furnace chamber with an interval partition wall structure. The lower part of the furnace is of a trousers-type structure, divided into two sections with air distribution plates arranged on the left and right, beneath which is an equal-pressure air chamber. Six “U”-shaped return material outlets, six external bed return material outlets, and ten boiler slag outlets are arranged around the lower part of the furnace.

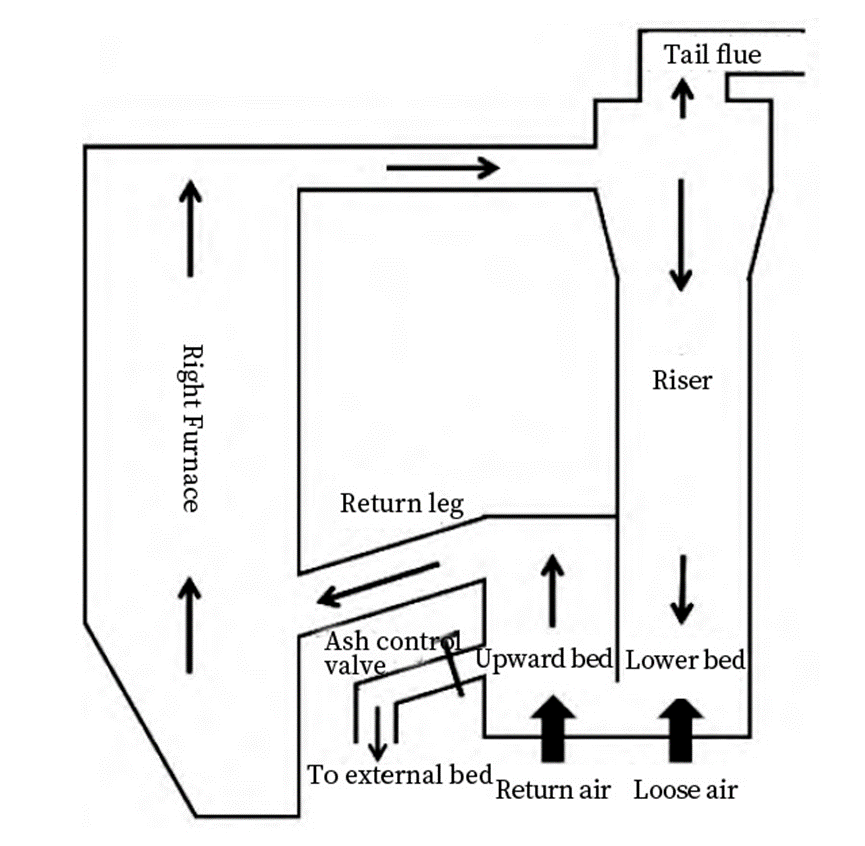

During the upward movement of the high-temperature gas-solid two-phase flow generated by combustion in the furnace, the furnace water-cooled wall and high-temperature superheater are heated. With increasing height and the decay of kinetic energy, larger diameter particles are continuously separated from the gas-solid two-phase flow, falling along the furnace walls to form internal circulation. Smaller diameter particles and ash, carried by the high-temperature flue gas, are tangentially introduced into six cyclone separators through top smoke windows and flue ducts. In the cyclone separators, most particles are separated, with the majority falling into the “U”-shaped return material device and the fine ash entering the vertical shaft flue. The particles in the “U”-shaped valve are effectively fluidized at the bottom by the action of fluidizing air, and under the pressure difference and gravity of the standpipe and return pipe, the fluidized material continuously returns to the furnace, forming a stable seal and external circulation, as shown in Figure 1.

The return material device adopts a non-mechanical “U”-shaped return material device[4-6](as shown in Figure 1), which is a self-balancing valve. The system achieves a stable working state by balancing the total pressure drop across various components, and the material circulation varies with changes in load. The “U”-shaped return material device consists of two small fluidized beds with bottom communication. The material ascends in one fluidized bed and descends in the other[7,8]. The descending small fluidized bed is generally referred to as the fluidized chamber, connected to the material leg below the cyclone separator, while the ascending small fluidized bed is connected to the transition inclined pipe leading to the main bed. The bottom of the “U”-shaped return material device is equipped with an air distribution device. By adjusting the valve at the bottom of the air distribution device, the particles in the ascending chamber of the “U”-shaped return material device are in a bubbling state, while the particles in the descending chamber are in a fluidized sliding state, maintaining a certain material level height to provide sufficient head to return the material from the “U”-shaped return material device to the furnace. Some fluidized material in the “U”-shaped return material device is introduced into six external beds under the control of their respective ash control valves, effectively controlling bed temperature to meet the heat absorption requirements of the heating surface and achieving bed material circulation. The upper and lower pressure values of the return material device can be used as the main basis for judging whether the return material is normal (see Table 1 provided in the manufacturer’s manual).

Figure 1: Simplified Diagram of the 660 MW Circulating Fluidized Bed Boiler Return Material System at Su Jinshuozhou Power

Table 1: Upper and Lower Pressure Values for Return Material Anomalies

Position Normal Value/kPa Poor Material Return/kPa

Upper Pressure <0 >10

Lower Pressure 0-2 >10When there is an abnormal return material condition, the bed temperature rapidly increases, the screen superheater experiences extensive overheating, reducing the service life of the heating surface, and may even lead to overheating and tube bursting. This not only compromises the load-carrying capacity of the boiler but also poses a risk to the overall operation. As the first 660 MW supercritical circulating fluidized bed boiler, with immature technology and no operational experience to draw upon, abnormal return material phenomena frequently occur during the commissioning process and initial production stages.

2. Anomalies in Return Material and Analysis of Causes

2.1 Initial Start-up

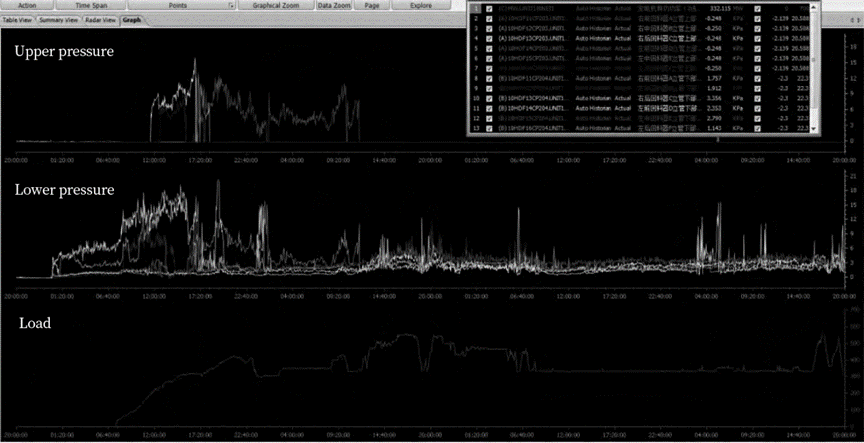

Figure 2 shows the DCS screen curves of the upper and lower pressures of the return material device, as well as real-time load, during the initial start-up of Boiler 1 (before grid connection) when an abnormal return material condition occurred.

Figure 2: Curves of Upper and Lower Pressures, Real-Time Load for Boiler 1 during Start-up

From Figure 2, it can be observed that during the occurrence of abnormal return material conditions, the following manifestations were evident: 1) The upper and lower pressures of the return material device’s standpipe fluctuated frequently and with a large amplitude, with the lower pressure exceeding 10 kPa; 2) The return material device’s entry into the furnace bed resulted in minimal circulating ash, and flue gas within the furnace entered the return material system through the return material leg, causing a reverse surge (short circuit). The reasons for this phenomenon are as follows: during the initial stage of bed temperature elevation in the start-up phase, a significant amount of material remains in the furnace bed from the previous shutdown, and the coal input is relatively small. The heat required for temperature rise comes from oil injection under the bed. At this stage, operators lack experience in handling this situation, and the control of primary air volume is too low, preventing the bed material from being in a good bubbling fluidized state. The pressure in the dense phase region of the furnace bed becomes high, causing a decrease in the pressure difference between the upper part of the ascending bed and the furnace bed return material outlet. This may even result in a flue gas short circuit, obstructing material return to the bed. Once normal return material is impeded, the ash accumulation in the return material device increases sharply, leading to a dramatic increase in the pressures of the standpipe’s upper and lower parts. At this point, to ensure the necessary pressure difference for normal return material, it is necessary to increase the pressure of the ascending bed, but the opening of the return material air door is limited by the amount of material separated by the separator. Therefore, in the initial start-up phase, it is essential to provide a primary air volume matching the bed material to ensure that the pressure in the dense phase region does not become excessively high, creating conditions for return material. Simultaneously, adjustments to the air volume of loosening air and return material air need to be made based on the amount of material retained in the standpipe and the separated material to maintain normal fluidized return material in the return material system. Generally, in the earliest stages of start-up, when there is a considerable amount of material retained in the lower part of the standpipe and the ascending bed, the air volume of loosening air and return material air should be appropriately increased.

2.2 Rapid Load Reduction and Load Increase

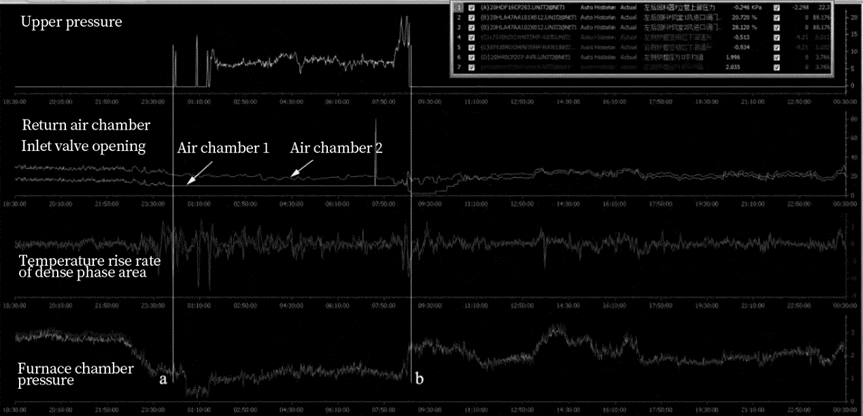

Figures 3 and 4 depict curves of standpipe pressure, load, return material device inlet valve opening, furnace pressure, and dense phase region temperature rise rate during a certain instance of abnormal return material occurrence after a rapid load reduction and subsequent load increase for Boiler 2.

Figure 3: Curves of Upper and Lower Pressures, Load for Boiler 2 during Abnormal Return Material

Figure 4: Curves of Return Material Device Air Chamber Inlet Valve Opening, Furnace Pressure, and Dense Phase Region Temperature Rise Rate for Boiler 2 during Abnormal Return Material

From the DCS curves, it can be observed that during the rapid load reduction phase (before point a), the pressure in the dense phase region of the furnace increases rapidly (indicating a decrease in negative pressure). This is due to the rapid decrease in load, where the normal slag discharge rate cannot promptly remove excess furnace slag, leading to a rapid increase in bed thickness and dense phase region pressure. This requires a timely increase in the return material air volume and loosening air volume to maintain the normal operation of the return material system. Subsequently, as the load decreases, the coal input and external circulating ash quantity also decrease, prompting adjustments to the return material air volume and loosening air volume. During the rapid load reduction phase, the obstruction of return material, accumulation of internal and external circulating ash in the standpipe (manifested as frequent fluctuations in upper and lower standpipe pressures, with the upper pressure exceeding 10 kPa), is caused by the failure to adjust the return material air volume and loosening air volume in a timely manner. During this period, the return material air volume and loosening air volume are often set to automatic mode, maintaining the originally set air volumes. As shown in the figures, during this process, the furnace pressure does not recover to normal operating values, and the dense phase region temperature rise rate remains greater than 0, indicating that the bed temperature remains relatively high. Starting from point b, the load begins to increase, and with the increase in coal quantity, the external circulating material also increases. This re-establishes a normal material circulation state within the return material device, and both upper and lower standpipe pressures, as well as the return material device air chamber inlet valve opening, return to normal values.

2.3 Prolonged Operation at Low Load

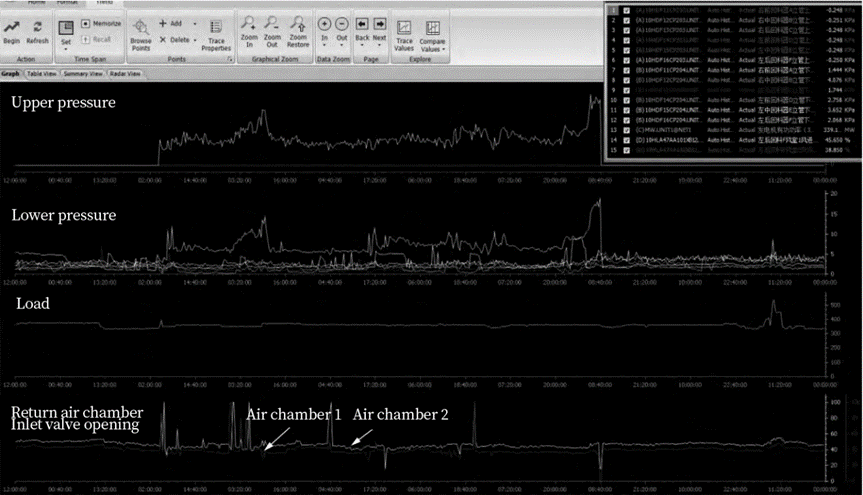

Figure 5 shows curves of standpipe pressure, load, and return material device inlet valve opening during an instance of abnormal return material occurrence for Boiler 1 during prolonged operation at low load.

Figure 5: Curves of Standpipe Pressure, Load, and Return Material Device Air Chamber Inlet Valve Opening for Boiler 1 during Abnormal Return Material

From Figure 5, it can be observed that during low-load operation, Boiler 1 experienced an increase in upper and lower standpipe pressures, maintaining at relatively high levels, indicating the accumulation of circulating ash in the standpipe and the inability to form normal return material. The cause of this phenomenon is as follows: during low-load operation, the coal input is minimal, resulting in a low system circulating ash quantity. Consequently, the required air volumes for loosening and return material are also low. If operators fail to notice this phenomenon, it can easily lead to over-adjustment, causing insufficient loosening and return material air volumes and affecting normal return material. From the curve in Figure 5, the fact that the inlet valves of the return material device air chamber and loosening air chamber are at the lowest opening provides evidence. Apart from operational control reasons, it is also related to the adjustment capability designed for the return material system under low-load conditions. When return material is obstructed, operators can appropriately increase the return material and loosening air volumes if allowed. Large-scale opening and closing operations of the inlet valves of the return material device air chamber can also be used to disturb the system, causing sudden changes in upper and lower pressures and restoring normal return material.

Additionally, during abnormal return material at low-load operation, it leads to a decrease in the ash input to the front external bed, weakened heat exchange, and a sudden drop in reheat steam temperature. In the subsequent recovery process, with the increase in load, once the return material returns to normal, if the ash control valve is not adjusted in time, a large amount of circulating material will enter the front external bed in a short time. This results in a sudden increase in reheat steam temperature and a significant decrease in boiler bed temperature, presenting a considerable challenge for operators to adjust[10].

2.4 Detachment of Casting Material in the Return Material Device

Due to poor control during the drying furnace process and the extended operation of the unit, partial detachment of casting material at the entrance of the cyclone separator and inside the return material device is common. The detached casting material settles at the bottom of the return material device, covering the upper part of the air chamber, thereby affecting the fluidization of material in the return material device. When the amount of detached casting material is small and in granular form, its impact on the fluidization of the return material device is minimal. However, if a significant amount of casting material detaches, it can lead to poor fluidization in the return material device, disrupt the return material balance, and result in intermittent return material. This affects the stable operation of the boiler and, in severe cases, can lead to blockage and coking in the return material device[11].

2.5 Blockage of the Return Material Device Air Cap

During the shutdown process of the unit, due to fluctuations in return material device air pressure and the detachment of casting material, a small amount of ash may reverse flow through the air cap to the bottom air chamber of the return material device. When the unit is restarted after a shutdown, the accumulation of ash or other debris in the air chamber may block a portion of the air cap. This results in poor local fluidization in the return material device during the initial ignition and warming-up period, affecting material circulation and sealing. In severe cases, it can lead to flue gas short circuits[11].

3 Measures to Address Abnormal Return Material

(1) Prior to Ignition:

Before ignition, a significant amount of material remains in the bed. During the initial startup, to ensure that the bed material is in a good bubbling fluidized state, it is necessary to provide a primary air volume (75% of the minimum fluidization air volume) that matches the retained material. In this bubbling fluidized state, the bed material is fluidized in the furnace, reducing the position of the dense phase region in the furnace and consequently lowering the pressure at the furnace return material port. This increases the pressure difference between the upper bed and the furnace return material port, facilitating normal return material and reducing the accumulation of circulating ash in the return material device, lowering the probability of return material abnormalities. Simultaneously, when initiating primary air for normal fluidization of the bed, it is crucial to also activate the fluidization air for the return material device. This ensures that the material retained in the return material device is in a fluidized state, reducing material accumulation and establishing normal return material. It also prevents flue gas from flowing back into the return material system. After the return material stabilizes, attention should be paid to whether the primary air volume is appropriate. Prolonged operation at low air volume may lead to the risk of poor local fluidization in the bed, causing material agglomeration and low-temperature coking, as well as hindered slag discharge.

(2) Rapid Load Reduction Phase:

During the rapid load reduction phase, when the dense phase region pressure in the bed rapidly increases, and ash accumulation in the return material device rises, leading to increased fluctuations in upper and lower standpipe pressures, there is a high risk of return material abnormalities. During this phase, it is necessary to promptly increase the air volume of the upper and lower bed air chambers based on the change in upper standpipe pressure. If needed, manual mode can be switched for adjustments, ensuring normal return material. In the process of rapid load increase, timely adjustments of coal quantity and air volume in an “incremental and frequent” manner are required. Bed pressure and temperature should be closely monitored to avoid significant fluctuations in bed temperature. Additionally, closely monitor changes in upper and lower standpipe pressures. Adjust the valve openings of both return material device air chambers appropriately to avoid sudden increases in return material causing secondary return material abnormalities.

(3) Prolonged Operation at Low Load:

During prolonged operation at low load, frequent fluctuations in upper and lower standpipe differential pressure may occur. This is due to a low ash quantity in the return material device during low-load conditions. To maintain the necessary ash quantity in the return material device while ensuring normal return material, adjust the air volume in the air chambers of both return material devices appropriately. If external bed ash input is not occurring, it may lead to a sudden drop in reheat steam temperature. Once abnormal temperatures in reheat steam, external bed, and high reheat outlet are detected, promptly open the ash control valve and adjust air volume. Increase disturbance in the external bed and fluidization air volume to ensure normal main and reheat steam temperatures and bed temperature.

(4) After Unit Shutdown:

After unit shutdown, conduct a comprehensive inspection of the return material device casting and the cyclone separator. Repair any detached or loosened casting material, assess wear and detachment of the air cap, and replace any defective air caps. If necessary, conduct resistance and material fluidization tests for the return material device air distribution plate. Regularly calibrate pressure signals, airflow measurement points, and differential pressure-based level signals for the return material device.

4 Conclusion

The normal operation of the return material in circulating fluidized bed boilers is crucial for the safe and economical operation of the unit[12]. To maintain normal return material, it is essential to ensure a dynamic balance of materials in both the bed and the return material system. During operation, operators should intensify the close monitoring of parameters in the bed and the return material system, promptly identify issues, and choose appropriate operational modes while implementing correct adjustments in response to identified problems. During boiler maintenance, special attention should be given to inspecting return material system equipment and addressing any defects, eliminating potential equipment hazards, and preventing shutdown accidents caused by return material system abnormalities.

References

[1] Jiao Dongxin. Causes and adjustment strategies of abnormal material return in circulating fluidized bed boiler

[J]. Energy and Energy Conservation, 2020( 12): 59-60, 72.

[2] Wang Shichang. Circulating fluidized bed boiler principle and operation [M]. Beijing: China Electric Power Press, 2016.

[3] Ning Xianyong. Analysis and treatment of circulating fluidized bed boiler reclaimer reclaim abnormality [J].

[J]. Nitrogen fertilizer, 2020( 1): 25-27.

[4] Peng Li, Li Hongzhong, Zhu Qingshan. Mathematical model of particle fluidization discharge under U-valve structure[J]. Journal of Process Engineering, 2012( 3) : 382-387.

[5]Yi Chen, Yuan Kong, Zhengqing Miao, Feng Xiao. Numerical simulation of gas-solid flow characteristics in a U-type valve by applying two-fluid model[J]. Boiler Technology, 2012( 6): 31-35

[6] Yan Zhoulin, Zhao Changsui. Experimental study on the characteristics of U-type valve for controlling fly ash circulation [J].

[J]. Combustion Science and Technology, 1997( 2): 109-113.

[7]Zhang Sihai, Chen Lujian, Zhang Aman, Tao Xin, Zhang Shouyu, Yang Hairui. Characteristics of circulating fluidized bed U-type return valve [J]. Journal of Chemical Engineering, 2019( 8) : 2954-2960.

[8] Guo Zongtao. Analysis of measures to prevent the interruption of circulating fluidized bed boiler return [J]. Industrial Boiler, 2016( 2) : 49-51.

[9] Wang Nianpeng. 260 t /h circulating fluidized bed boiler ignition early return material adjustment and analysis[J]. Inner Mongolia Coal Economy, 2021( 8) : 197-198.

[10] Li Shu. 300 MW fluidized bed boiler reheat steam temperature anomaly analysis and treatment [J].

[J]. Shandong Industrial Technology, 2014( 22): 15.

[11]Chen Yumin, Huang Xibing. Causes and treatment of clogging of reclaimer in CFB boiler

[J]. Guizhou electric power technology, 2016( 1) : 30-31.

[12]Wang Xiaodong, Zhang Jun, Tan Wei. Analysis and treatment of abnormalities of 130 t /h circulating fluidized bed boiler reclaimer[J]. Shandong Chemical Industry, 2012( 7) : 55-57.

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.