If you’re a boiler buyer searching for the perfect solution to meet your energy needs while prioritizing efficiency, sustainability, and cost-effectiveness, then you’ve come to the right place.

We will unravel the mysteries surrounding fluidized bed boilers and showcase why they are the ideal choice for buyers seeking a cutting-edge, forward-thinking solution. From understanding the inner workings of fluidized bed boilers to exploring their myriad advantages over traditional systems, we leave no stone unturned.

How do fluidized bed boilers work?

The boilers are a fascinating and innovative technology that revolutionizes the way we generate heat and produce energy. Understanding how fluidized bed boilers work is crucial to appreciating their numerous advantages and why they are the perfect choice for boiler buyers looking to fuel the future.

At the heart of a fluidized bed boiler is the concept of fluidization. Unlike traditional boiler systems where fuel is combusted on a fixed grate or in a pulverized state, boilers introduce a dynamic and fluid-like environment. This is achieved by suspending solid particles, known as bed material, in a high-velocity stream of air or gas.

When the air or gas flows through the bed material, it creates a fluidized state where the particles behave like a liquid, circulating and mixing with each other. The bed material, typically sand or limestone, acts as both the heat transfer medium and the combustion medium.

As fuel, such as coal, biomass, or even waste materials, is introduced into the fluidized bed, it reacts with the oxygen present in the air or gas. The high turbulence and intimate contact between the fuel and the bed material ensure efficient combustion and heat transfer. This results in enhanced combustion efficiency and reduced emissions of pollutants compared to traditional boiler systems.

One of the key features of fluidized bed boilers is their ability to handle a wide range of fuels. The fluidized bed environment allows for the effective combustion of various types of fuels, including low-quality coals, biomass, and even waste materials. This fuel flexibility is a significant advantage for boiler buyers who seek a versatile solution to accommodate different fuel sources or have access to unconventional or low-cost fuels.

Furthermore, the fluidized bed environment promotes better mixing and heat transfer, leading to improved combustion efficiency. The turbulent movement of the bed material ensures that fuel particles are thoroughly exposed to the oxygen-rich air or gas, maximizing the combustion process. This enhanced efficiency translates into higher energy conversion rates and ultimately reduced fuel consumption.

Another noteworthy aspect of fluidized bed boilers is their environmental friendliness. The fluidized bed’s inherent design allows for the effective capture and control of harmful emissions, such as sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. Through the injection of sorbents or the utilization of limestone bed material, boilers can achieve high levels of flue gas desulfurization, minimizing the release of sulfur compounds. Additionally, the lower combustion temperatures and longer residence times in the fluidized bed mitigate the formation of nitrogen oxides, contributing to cleaner air and reduced environmental impact.

Fluidized bed boilers work by creating a dynamic and fluid-like environment where solid particles are suspended and mixed with a high-velocity stream of air or gas. This innovative design promotes efficient combustion, fuel flexibility, and environmental sustainability. By harnessing the power of fluidization, these boilers offer improved combustion efficiency, reduced emissions, and the ability to utilize a diverse range of fuels. As boiler buyers, understanding the inner workings of fluidized bed boilers will empower you to make informed decisions and choose the ideal solution for your energy needs.

If you are interested in learning more about fluidized bed boilers, you can check out these websites:

- Fluidized Bed Boiler – an overview | ScienceDirect Topics

- Valmet BFB Boiler utilizing bubbling fluidized bed technology

- Circulating Fluidized-Bed Boilers (CFBs) » Babcock & Wilcox

Enhanced combustion efficiency: How fluidized bed boilers optimize fuel utilization

The fluidized bed environment created within these boilers plays a crucial role in optimizing fuel utilization. Unlike traditional combustion systems, the boilers introduce a dynamic and turbulent atmosphere where solid particles are suspended and mixed with a high-velocity stream of air or gas. This turbulence and intimate contact between the fuel and the bed material result in efficient combustion.

One of the factors contributing to enhanced combustion efficiency is the increased residence time of the fuel within the fluidized bed. The bed material acts as a heat transfer medium, facilitating the transfer of heat from the fluidized bed to the fuel particles. This extended residence time, combined with the uniform distribution of heat throughout the bed, ensures that fuel particles have ample time to fully combust, leading to improved fuel utilization.

Furthermore, the mixing and turbulence within the fluidized bed promote better oxygen availability for the combustion process. The high velocity of the air or gas stream ensures that fuel particles are continuously exposed to oxygen-rich environments, allowing for more complete and efficient combustion. This feature is particularly advantageous when dealing with fuels that are difficult to burn or have varying composition, such as biomass or waste materials.

In addition to the inherent advantages of the fluidized bed environment, fluidized bed boilers often incorporate advanced technologies to further optimize combustion efficiency. For instance, the use of staged combustion techniques, such as overfire air or secondary air injection, helps ensure optimal mixing of fuel and air, minimizing the formation of pollutants and maximizing combustion efficiency.

Another aspect that contributes to enhanced fuel utilization is the ability of fluidized bed boilers to handle a wide range of fuel types. This fuel flexibility allows boiler buyers to utilize various fuel sources, including low-quality coals, biomass, and even waste materials. By accommodating different fuels, the boilers offer greater versatility and the opportunity to optimize fuel utilization based on availability, cost, or environmental considerations.

The combination of extended residence time, efficient mixing, and fuel flexibility makes fluidized bed boilers highly efficient in extracting energy from the fuel. This increased combustion efficiency translates into several benefits for boiler buyers, including reduced fuel consumption, lower operating costs, and reduced emissions.

Fluidized bed boilers optimize fuel utilization and enhance combustion efficiency through several mechanisms. The dynamic and turbulent fluidized bed environment, coupled with extended residence time and efficient mixing, ensures that fuel particles are thoroughly combusted, minimizing waste and maximizing energy extraction. Furthermore, the fuel flexibility of fluidized bed boilers allows for the efficient utilization of a wide range of fuel types, further optimizing fuel utilization and providing versatility to boiler buyers. By choosing a fluidized bed boiler, buyers can expect improved fuel efficiency, cost savings, and reduced environmental impact.

Case studies: Success stories of fluidized bed boilers in various industries

Fluidized bed boilers have proven to be highly successful and efficient in various industries, offering tangible benefits and fueling the progress towards more sustainable and cost-effective energy solutions. Let’s explore some compelling case studies that highlight the success stories of fluidized bed boilers in different sectors.

Power Generation

One notable success story is the use of boilers in power generation plants. For instance, a large-scale coal-fired power plant in Asia implemented a fluidized bed boiler system, significantly improving its efficiency and reducing emissions. By harnessing the fluidized bed technology, the plant achieved higher combustion efficiency, lower fuel consumption, and a substantial reduction in nitrogen oxide (NOx) emissions. This case study exemplifies how fluidized bed boilers can transform conventional power generation and contribute to cleaner and more sustainable electricity production.

Biomass Energy

Fluidized bed boilers have emerged as a game-changer in biomass energy production. In a biomass plant located in Europe, a fluidized bed boiler system was employed to generate heat and electricity from various organic waste materials, including agricultural residues and forestry by-products. The fluidized bed technology enabled efficient combustion of diverse biomass feedstocks, ensuring optimal energy utilization and minimal environmental impact. The success of this case study highlights the potential of fluidized bed boilers to support renewable energy initiatives and reduce reliance on fossil fuels.

Waste-to-Energy

Fluidized bed boilers have also demonstrated their effectiveness in waste-to-energy applications. In a waste-to-energy facility in North America, the boilers were utilized to convert municipal solid waste into electricity and heat. The fluidized bed technology enabled efficient combustion of the waste, ensuring high energy recovery rates and minimal emissions. The success of this case study showcases how fluidized bed boilers can play a pivotal role in waste management strategies by converting waste materials into valuable energy resources.

Industrial Applications

Fluidized bed boilers have found widespread applications in various industrial sectors, including chemical, petrochemical, and manufacturing industries. For instance, in a chemical plant in Europe, a fluidized bed boiler system was employed for steam generation and process heating. The versatility and fuel flexibility of fluidized bed boilers allowed the plant to utilize a wide range of fuels, including low-grade fuels and biomass, resulting in cost savings and improved operational efficiency. This case study highlights the adaptability of the boilers in meeting the unique energy demands of industrial processes.

These case studies serve as compelling evidence of the success and efficacy of the boilers in diverse industries. By optimizing combustion efficiency, reducing emissions, and providing fuel flexibility, fluidized bed boilers offer tangible benefits, including improved energy efficiency, cost savings, and reduced environmental impact. These success stories underscore the transformative potential of fluidized bed boilers in shaping a more sustainable and energy-efficient future across various sectors.

Comparison of fluidized bed boilers with other advanced boiler technologies

We will compare fluidized bed boilers with other advanced boiler technologies, highlighting their unique features, advantages, and suitability for different applications.

Fluidized Bed Boilers vs. Pulverized Coal Boilers:

Pulverized coal boilers are widely used in power generation, and while they have their merits, fluidized bed boilers offer distinct advantages. Fluidized bed boilers have the ability to burn a wider range of coal types, including low-grade coals and coal with high moisture content, with high combustion efficiency. They also have better fuel flexibility, as they can utilize biomass and other solid fuels in addition to coal. Moreover, fluidized bed boilers have lower emissions of nitrogen oxides (NOx) compared to pulverized coal boilers, making them more environmentally friendly.

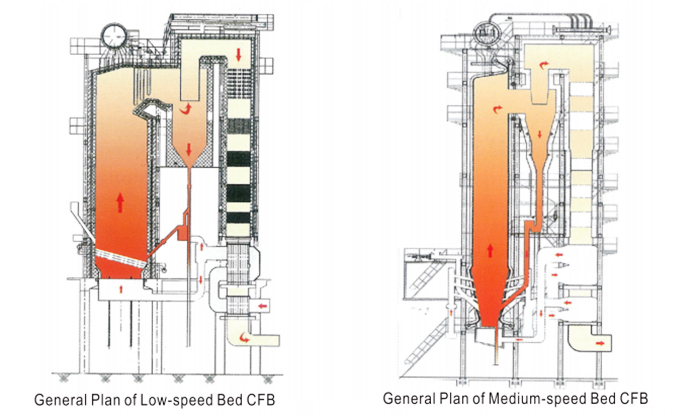

Fluidized Bed Boilers vs. Circulating Fluidized Bed (CFB) Boilers:

Circulating fluidized bed (CFB) boilers are a subtype of fluidized bed boilers and share similarities with their fluidized bed counterparts. The key difference lies in the recirculation of bed material and the higher gas velocities in CFB boilers, resulting in enhanced heat transfer and combustion efficiency. CFB boilers are particularly suitable for larger-scale applications, such as power generation, due to their ability to handle higher capacities. However, fluidized bed boilers offer advantages in terms of fuel flexibility, lower maintenance requirements, and better control of bed material inventory.

DHB CFB boilers Technical parameters

| Name | Unit | Spec. | |

| Model | DH-35/3.82-M | DH-35/5.3-M | |

| Rated Evaporation Capacity | t/h | 35 | 35 |

| Maximum Continuous Evaporation | t/h | 35 | 35 |

| Rated Steam Pressure | MPa | 3.82 | 5.3 |

| Rated Steam Temperature | ℃ | 450 | 450 |

| Feed Water Temperature | ℃ | 150 | 150 |

| Adaptive Fuels | Anthracite,lean coal,bituminous coal,lignite,petroleum coke,etc. | ||

| Water side resistance of boiler body | MPa | 0.3 | 0.5 |

| Steam side resistance of the boiler body | MPa | 0.4 | 0.4 |

| Primary wind-side resistance | Pa | 12000 | 12000 |

| Secondary wind-side resistance | Pa | 8000 | 8000 |

| Induced air-side resistance | Pa | 3600 | 3600 |

| Feed return device resistance | Pa | 18000 | 18000 |

| Hearth height | m | 22 | 22 |

| Hearth section | ㎡ | 9.6 | |

| Air distribution plate section | ㎡ | 5.7 | |

| Residence time of flue gas inside the hearth | Sec | >5 | |

| Number of separators | Set | 2 | |

| Separator Type | Membrane-type wall steam cooling (or water cooling) or steel plate heat-insulation type, volute type. | ||

| Inner diameter of separator | m | 1.9 | |

| Separator separation efficiency | % | >99.5 | |

| Number of coal feeders | Set | 2 | |

| Superheater attemperation mode | By spraying the self-produced condensed water or feed water | ||

| Carbon content in boiler ashes (when burning the bituminous coal) | % | ﹤6 | |

| Temperature of the preheated air | ℃ | 141 | |

| Temperature of the exhaust flue gas | ℃ | 144 | |

| Elevation of the operating level | m | 7 | |

| Elevation of the boiler roof plate | m | 33 | |

DHB boiler also has two other high power boilers,75t/H CFB and 130t/H CFB

CFB Boiler – Industrial Boilers Manufacturer (dhbboiler.com)

Fluidized Bed Boilers vs. Biomass Boilers:

Biomass boilers are designed specifically for the combustion of organic biomass materials, such as wood pellets, agricultural residues, or dedicated energy crops. While fluidized bed boilers can also burn biomass, they provide additional benefits. The boilers offer superior fuel flexibility, allowing the combustion of various biomass feedstocks with high efficiency. Additionally, fluidized bed boilers can handle higher moisture content in biomass fuels, reducing the need for extensive fuel drying. The fluidized bed environment also promotes efficient combustion and reduced emissions, making fluidized bed boilers a preferred choice for biomass energy production.

Fluidized Bed Boilers vs. Supercritical Boilers:

Supercritical boilers operate at higher pressures and temperatures to achieve greater thermal efficiency. While supercritical boilers are efficient, they have limitations in fuel flexibility. Fluidized bed boilers excel in this aspect by accommodating a wider range of fuels, including low-quality coals, biomass, and waste materials. Moreover, fluidized bed boilers offer better combustion efficiency and lower emissions of pollutants, making them an attractive option for environmentally conscious applications.

In summary, fluidized bed boilers offer several advantages compared to other advanced boiler technologies. They provide fuel flexibility, efficient combustion, and reduced emissions, making them suitable for a variety of applications, including power generation, waste-to-energy, and industrial processes. While other advanced boiler technologies have their merits in specific scenarios, fluidized bed boilers excel in terms of versatility, fuel flexibility, and environmental performance.

FAQ

Here’s a list of commonly asked questions and their corresponding answers related to fluidized bed boilers:

Q1: What is a fluidized bed boiler?

A1: A fluidized bed boiler is a type of boiler that suspends solid particles, such as sand or limestone, in a high-velocity stream of air or gas. This creates a fluid-like environment where the particles circulate and mix, facilitating efficient combustion and heat transfer.

Q2: How do fluidized bed boilers achieve better combustion efficiency?

A2: Fluidized bed boilers optimize combustion efficiency through factors such as extended residence time, efficient mixing, and fuel flexibility. The turbulent fluidized bed environment ensures thorough exposure of fuel particles to oxygen, resulting in more complete combustion and higher energy conversion rates.

Q3: What fuels can be used in fluidized bed boilers?

A3: Fluidized bed boilers offer excellent fuel flexibility, allowing for the combustion of a wide range of fuels. Common fuel types include coal, biomass (such as wood pellets or agricultural residues), waste materials, and even low-quality or unconventional fuels.

Q4: What are the environmental benefits of fluidized bed boilers?

A4: Fluidized bed boilers have several environmental benefits. They achieve lower emissions of pollutants, such as sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter, compared to traditional boiler systems. Additionally, the fuel flexibility and efficient combustion of fluidized bed boilers contribute to reduced reliance on fossil fuels and support the utilization of renewable energy sources.

Q5: How do fluidized bed boilers handle varying fuel properties and moisture content?

A5: Fluidized bed boilers are designed to handle a wide range of fuel properties and moisture content. The dynamic and turbulent nature of the fluidized bed environment ensures efficient combustion, even with varying fuel compositions. Additionally, fluidized bed boilers can accommodate fuels with higher moisture content, reducing the need for extensive fuel drying.

Q6: What are the maintenance considerations for fluidized bed boilers?

A6: Fluidized bed boilers require regular maintenance to ensure optimal performance. This includes monitoring and maintaining the proper fluidized bed temperature, inspecting and cleaning heat transfer surfaces, and managing bed material inventory. Regular inspection and maintenance of emission control systems, such as flue gas desulfurization, are also essential.

Q7: Can fluidized bed boilers integrate with renewable energy sources?

A7: Yes, fluidized bed boilers can integrate with renewable energy sources. For example, they can effectively combust biomass and support the utilization of biomass energy. Additionally, fluidized bed boilers can be coupled with other renewable energy systems, such as solar thermal or geothermal systems, to provide combined heat and power solutions.

Q8: What are the cost savings associated with fluidized bed boilers?

A8: Fluidized bed boilers offer potential cost savings through improved fuel efficiency and reduced fuel consumption. The ability to utilize a wide range of fuels, including lower-cost or waste materials, can also contribute to cost savings. Additionally, the lower emissions and environmental compliance of fluidized bed boilers may result in reduced regulatory costs.

Q9: Are fluidized bed boilers suitable for both large-scale and smaller-scale applications?

A9: Yes, fluidized bed boilers can be designed for a range of capacities, making them suitable for both large-scale power generation and smaller-scale industrial applications. Their versatility and fuel flexibility allow for customization based on the specific requirements of different applications.

Q10: How do fluidized bed boilers compare to other advanced boiler technologies?

A10: Fluidized bed boilers offer advantages such as fuel flexibility, efficient combustion, and reduced emissions compared to other advanced boiler technologies. They excel in accommodating a wider range of fuels, including biomass and waste materials. Additionally, fluidized bed boilers optimize combustion efficiency and provide environmental benefits, making them a preferred.

Don’t settle for ordinary boilers! Join the ranks of smart buyers who are embracing fluidized bed technology. Click here to learn more about how fluidized bed boilers can fuel your future and unlock a world of benefits for your energy needs!