If you’re a facility owner or manager seeking a heating solution that not only provides exceptional performance but also delivers substantial financial benefits, you’ve come to the right place.

In today’s competitive industrial landscape, making smart investment decisions is crucial. That’s why we’re here to shed light on the undeniable advantages of CFB (Circulating Fluidized Bed) boilers and their ability to elevate your facility’s profitability while aligning with environmental sustainability goals.

Throughout this comprehensive blog post, we’ll delve into the diverse aspects that make CFB boilers the epitome of a wise investment. From their remarkable efficiency and cost-saving potential to their positive environmental impact, we leave no stone unturned.

Understanding the Technology: How CFB Boilers Work

CFB (Circulating Fluidized Bed) boilers have gained immense popularity in the industrial heating landscape due to their unique and efficient operating principles. To truly grasp why CFB boilers are a smart investment for your facility, it’s essential to delve into the inner workings of this innovative technology.

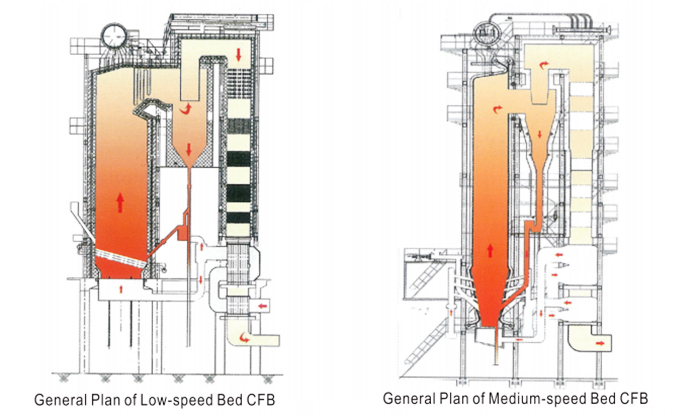

At the heart of a CFB boiler lies the circulating fluidized bed combustion process, which sets it apart from conventional boilers. Unlike traditional systems that rely on a stationary bed of fuel, CFB boilers utilize a bed of solid particles, typically sand or limestone, suspended in a high-velocity stream of combustion air.

The magic happens within the combustion chamber, where the bed of particles exhibits fluid-like behavior. This fluidization enables excellent mixing, uniform heat transfer, and efficient combustion of various fuel types, ranging from coal and biomass to waste materials. The result is a highly responsive and flexible system capable of accommodating diverse fuel sources, making CFB boilers an attractive choice for facilities seeking sustainability and fuel flexibility.

The key to this fluidized bed combustion process lies in the intense mixing of solid particles and combustion air. The upward velocity of the air keeps the particles buoyant, forming a bubbling or turbulent bed. As fuel is introduced into the furnace, it undergoes combustion within this dynamic bed, releasing heat energy.

To capture this heat energy, CFB boilers feature a heat exchange surface immersed within the bed. This surface, often comprised of tubes or panels, absorbs the heat and transfers it to a fluid, typically water or steam, circulating through the heat exchange system. The heated fluid can then be utilized for various purposes, such as generating steam for industrial processes or providing space heating.

One of the remarkable advantages of CFB boilers is their ability to maintain stable combustion and control emissions. The intense mixing and turbulence within the fluidized bed create an ideal environment for thorough combustion, resulting in reduced emissions of harmful pollutants like nitrogen oxide (NOx) and sulfur dioxide (SO2). This inherent emission control capability helps facilities meet stringent environmental regulations while contributing to a cleaner and healthier surrounding environment.

Furthermore, the fluidized bed combustion process also facilitates efficient utilization of fuel. The turbulent conditions and longer residence time of particles in the bed ensure a high combustion efficiency, extracting the maximum energy from the fuel. This increased combustion efficiency translates to lower fuel consumption and reduced operating costs, making CFB boilers a cost-effective choice for long-term operations.

In summary, CFB boilers harness the power of circulating fluidized bed combustion, where solid particles are suspended in a high-velocity stream of combustion air. This technology offers numerous benefits, including fuel flexibility, efficient combustion, emission control, and cost savings. Understanding the inner workings of CFB boilers allows facility owners and managers to appreciate the intelligent design and engineering behind these systems, empowering them to make informed decisions when it comes to heating their facilities.

DHB CFB (Circulating Fluidized Bed) boilers

The circulating fluidized bed boiler produced by our Company can better adapt to the distribution and area of the Global coal resources.

Meanwhile, DHB CFB boilers further contribute to a greener environment by changing energy sources from limited energy sources such as coal and natural gas to fuelwood, wood waste, agricultural straw, livestock manure, sugar crop residue, municipal waste and sewage, aquatic plants, and other waste materials from production processes as energy sources.

Based on the successful operation of circulating fluidized bed boilers made by partner manufacturers, our Company has successfully developed and manufactured the circulating fluidized bed boilers of the 20-220t/h parameter levels with the following characteristics:

- Boiler efficiency ≧ 90%;

- Steam-cooling (water-cooling) volute-type cyclone separator;

- Steam-cooling (water-cooling) wrapped wall structure is adopted in the rear superheater area;

- The rear economizer guard-plate furnace wall adopts the guard-plate frame-type light walls, and the boiler has good sealing performance;

- Steel structure design: The boiler structure is strictly calculated with finite elements to ensure reasonable load distribution;

- Optimization of the primary/ secondary wind ratio can reduce the power consumption, enhance the disturbance of flue gas to prolong the residence time of flue gas in the furnace, and improve the boiler efficiency;

- Large cross section of hearth, long-time stay of flue gas in the furnace, low rising speed of furnace, large circulating amount in the furnace, increase of the primary burnout rate, and significant reduction of the abrasion of the water-cooling hearth wall area.

Parameter of this customized circulating fluid bed with the best price

130t/H CFB

Technical Parameters for the 130t per hour CFB

75t/H CFB

Technical Parameters for the 75t per hour CFB

35t/H CFB

Technical Parameters for the 35t per hour CFB

Long-Term Savings: Calculating the Financial Benefits of CFB Boilers

When considering investments for your facility, it’s essential to assess the long-term financial benefits. CFB (Circulating Fluidized Bed) boilers, with their remarkable efficiency and cost-saving potential, prove to be a wise choice for maximizing your return on investment.

One of the primary factors contributing to the long-term savings offered by CFB boilers is their exceptional combustion efficiency. The fluidized bed combustion process within CFB boilers ensures thorough mixing of fuel and air, resulting in efficient and complete combustion. This means that a higher percentage of the fuel’s energy content is converted into usable heat, reducing wasted energy and fuel consumption.

Reduced fuel consumption directly translates to substantial cost savings over time. By maximizing the utilization of fuel resources, CFB boilers can significantly lower your facility’s operating expenses. Whether you rely on coal, biomass, or other alternative fuels, the efficient combustion of CFB boilers allows you to achieve the desired heat output with minimal fuel input.

Furthermore, CFB boilers offer the flexibility to utilize a wide range of fuel types. This versatility opens up opportunities to explore more cost-effective and sustainable fuel options. For instance, if the price of one fuel source increases significantly, you have the flexibility to switch to an alternative fuel that is more affordable without requiring significant modifications to the boiler system. This adaptability provides you with a strategic advantage in managing fuel costs and optimizing your budget.

Maintenance costs also play a crucial role in determining the long-term savings of CFB boilers. These boilers are designed with robust and reliable components, reducing the frequency of repairs and minimizing downtime. Additionally, the fluidized bed combustion process inherently mitigates issues such as fouling and slagging, which can impact the efficiency and reliability of traditional boilers. As a result, CFB boilers often require less maintenance, leading to lower maintenance expenses and increased operational efficiency.

To accurately evaluate the financial benefits of CFB boilers, it’s important to consider the entire lifecycle cost. While the upfront investment for a CFB boiler may be higher than that of conventional boilers, it’s crucial to factor in the long-term savings in fuel costs, maintenance expenses, and potential incentives or rebates offered for using efficient and sustainable heating systems. Conducting a comprehensive lifecycle cost analysis will provide a clearer picture of the overall financial advantage that CFB boilers offer.

Additionally, when calculating the financial benefits, it’s important to consider the potential for government incentives, grants, or tax credits that promote energy efficiency and sustainability. Many jurisdictions offer financial support or incentives for adopting clean energy solutions, including high-efficiency boilers like CFB boilers. Taking advantage of such programs can further enhance the financial benefits and shorten the payback period of your investment.

In conclusion, CFB boilers offer substantial long-term savings by virtue of their efficient combustion, fuel flexibility, and lower maintenance requirements. By carefully evaluating the lifecycle cost, incorporating fuel cost savings, and considering potential incentives, you can accurately assess the financial benefits that CFB boilers bring to your facility. These boilers provide a solid foundation for maximizing ROI and ensuring a cost-effective heating solution for years to come.

Related news about government subsidies

The U.S. Department of Energy (DOE) provides acquisition guidance for large commercial boilers, a product category covered by FEMP-designated efficiency requirements¹. Federal purchases of commercial boilers must meet or exceed the minimum efficiency requirements and thermal efficiencies listed in Table 1¹. FEMP has calculated that a 3,000,000 Btu/h gas-fired hot water commercial boiler meeting the required combustion efficiency level of 96.0% E c saves money if priced no more than $105,000 above the base model¹.

The United States is taking a new look at industrial subsidies in response to the vast subsidies in China and other countries that have non-market approaches to industrial development and provide government subsidies to a range of industries, such as 5G, semiconductors, steel, high-performance computers, and maritime vessels². The United States has passed two bills endorsed by the Biden administration: The United States Innovation and Competition Act (USICA) and The Infrastructure Investment and Jobs Act (Infrastructure Bill), which call for major new government-financed investments in artificial intelligence, 5G telecommunications technology, semiconductors, biotech, quantum computing, bridges and pipelines, rail and buses, low-cost broadband, plug-in electric vehicle charging stations, and environmental remediation².

The United States is also working to reform global fossil fuel subsidies, which are estimated to be over $500 billion per year³. The United States has proposed a new initiative to restart international cooperation on fossil fuel subsidy reform at the G20 level, which would include a peer review mechanism, a reporting framework, and a roadmap for phasing out inefficient subsidies³.

Source:

(1) Purchasing Energy-Efficient Large Commercial Boilers. https://www.energy.gov/femp/purchasing-energy-efficient-large-commercial-boilers.

(2) The United States Takes a New Look at Industrial Subsidies – CSIS. https://www.csis.org/analysis/united-states-takes-new-look-industrial-subsidies.

(3) Reforming global fossil fuel subsidies: How the United States can …. https://www.brookings.edu/research/reforming-global-fossil-fuel-subsidies-how-the-united-states-can-restart-international-cooperation/.

By exploring these subtopics in depth, we aim to provide you with a holistic understanding of the remarkable benefits that CFB boilers bring to the table. Whether you’re looking to optimize energy consumption, reduce operational costs, or minimize your environmental footprint, CFB boilers offer a solution that checks all the boxes.

Join us on this enlightening journey as we unravel the secrets behind maximizing ROI with CFB boilers. Prepare to discover why they have become the go-to choice for forward-thinking facility owners and managers.

Don’t miss out on the financial benefits and long-term savings offered by CFB boilers. Click here to learn more about how these intelligent systems can revolutionize your facility’s heating. Request a quote now!