In today’s fast-paced industrial landscape, optimizing boiler operations is a top priority for businesses seeking increased efficiency and reduced costs.

Understanding Boiler Superheaters: An Overview of Function and Purpose

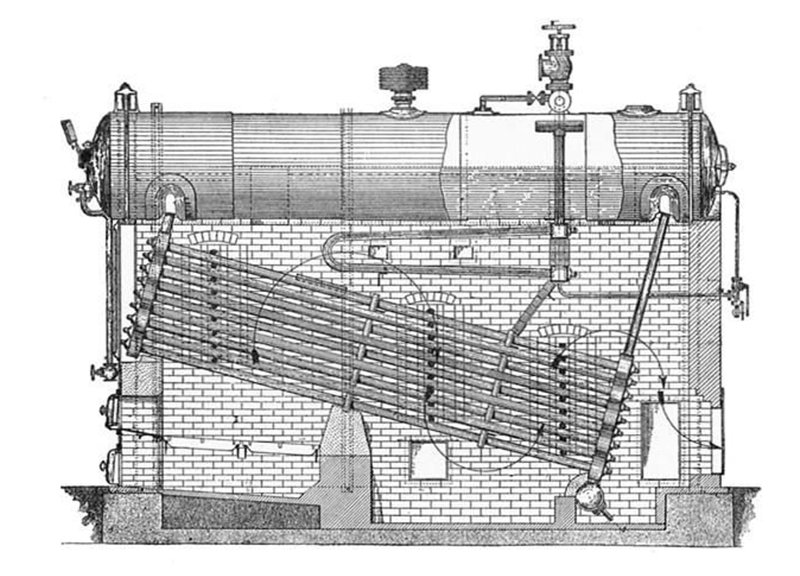

At its core, a boiler superheater is a heat exchanger component that is integrated into the boiler system. Its primary function is to further heat the saturated steam generated in the boiler, elevating its temperature to a superheated state. This superheated steam holds tremendous value as it possesses significantly higher energy content compared to saturated steam.

By superheating the steam, boiler superheaters enable various industrial processes to operate at elevated temperatures, allowing for more efficient and effective heat transfer. This leads to improved overall system efficiency, faster response times, and enhanced control over steam quality and temperature.

One of the key purposes of boiler superheaters is to maximize the thermal energy output of the boiler system. As the superheated steam retains higher energy levels, it provides a more powerful heat source for industrial applications such as power generation, heating, and process heating. This allows businesses to extract the maximum potential from their boilers, resulting in increased productivity and operational efficiency.

Furthermore, boiler superheaters also contribute to reducing moisture content in the steam. Saturated steam contains a certain amount of water droplets, which can have adverse effects on equipment and processes that require dry steam. By superheating the steam, the moisture content is significantly reduced, ensuring a drier and more reliable steam supply for critical operations.

In summary, the function and purpose of boiler superheaters are twofold: to elevate the temperature of steam to a superheated state and to maximize the thermal energy output of the boiler system. By doing so, boiler superheaters enhance overall system efficiency, provide a more powerful heat source, and deliver drier steam for various industrial applications.

Types of Boiler Superheaters: A Comparative Analysis for Buyers

When it comes to boiler superheaters, there are several types available in the market, each offering unique features and advantages. We will provide a comprehensive comparative analysis of the different types of boiler superheaters, empowering buyers to make informed decisions based on their specific requirements.

Radiant Superheaters:

Radiant superheaters are one of the most common types employed in boiler systems. Positioned in the radiant zone of the boiler, these superheaters absorb radiant heat directly from the combustion flame. This type of superheater is known for its high heat transfer efficiency and quick response time, making it ideal for applications that demand rapid temperature increases.

Convective Superheaters:

Convective superheaters, as the name suggests, are positioned in the convective zone of the boiler. They are designed to absorb heat from the flue gas as it passes through the convective section. Convective superheaters are known for their larger heat transfer surface area, allowing for efficient heat absorption and uniform temperature distribution. They are commonly used in boilers with high steam production rates and varying load conditions.

Combination Superheaters:

Combination superheaters, as the name implies, combine the characteristics of both radiant and convective superheaters. They are positioned strategically within the boiler system to take advantage of both radiant and convective heat transfer mechanisms. This type of superheater offers a balanced approach, providing high efficiency and uniform temperature distribution.

Reheaters:

Reheaters are a specialized type of superheater that is typically used in power generation applications. Positioned in the steam path after the initial superheating stage, reheaters reheat the steam to further increase its temperature. By doing so, they improve the overall efficiency of power plants by maximizing the expansion of steam in the turbine, resulting in increased power generation capacity.

When selecting the appropriate type of boiler superheater, several factors should be considered. These include the specific requirements of the application, steam temperature and pressure parameters, load variations, fuel type, and space limitations within the boiler system. By carefully assessing these factors and consulting with industry experts, buyers can identify the most suitable type of superheater that aligns with their operational needs and performance goals.

In conclusion, understanding the different types of boiler superheaters and their respective advantages is crucial for buyers seeking to maximize the performance and savings of their boiler systems. Radiant superheaters, convective superheaters, combination superheaters, and reheaters each offer unique features and benefits. By conducting a thorough comparative analysis and considering the specific requirements of their applications, buyers can make informed decisions and select the most suitable type of superheater. This ensures optimal heat transfer efficiency, improved system performance, and ultimately, enhanced operational savings.

Now that we have explored the types of boiler superheaters, let’s move on to the next section, where we will discuss the key considerations that buyers should keep in mind when selecting the right superheater for their specific needs.

Key Considerations for Selecting the Right Boiler Superheater

Selecting the right boiler superheater is a critical decision that can greatly impact the performance, efficiency, and overall success of a boiler system. In this section, we will explore the key considerations that buyers should keep in mind when selecting the most suitable superheater for their specific needs.

- Steam Parameters:

The first consideration when selecting a boiler superheater is the desired steam parameters. This includes factors such as steam temperature, pressure, and flow rate. Understanding the required steam parameters is crucial in determining the appropriate type, size, and capacity of the superheater. Buyers should ensure that the selected superheater can effectively meet the desired steam conditions. - Boiler Type and Design:

Different boiler types and designs may require specific superheater configurations. It is important to consider the compatibility between the boiler and the superheater. Factors such as the boiler’s heat transfer mechanism, fuel type, combustion process, and overall system design should be taken into account to ensure seamless integration and optimal performance. - Material Selection:

The material selection for the superheater is vital for its durability, reliability, and resistance to high temperatures and corrosive environments. Depending on the operating conditions and fuel characteristics, different materials, such as stainless steel, alloy steel, or nickel-based alloys, may be required. Buyers should consult with manufacturers or industry experts to determine the most suitable material for the specific application. - Superheater Configuration:

The configuration of the superheater, including its positioning and arrangement within the boiler system, is another crucial consideration. Factors such as the available space, accessibility for maintenance and inspection, and the impact on overall system efficiency should be evaluated. Proper placement and arrangement of the superheater contribute to optimal heat transfer and ease of operation. - Maintenance and Cleanliness:

Buyers should also consider the maintenance requirements and ease of cleaning associated with the chosen superheater. Regular maintenance and cleaning are essential for the longevity and efficiency of the superheater. Factors such as accessibility for cleaning, the presence of soot blowers or other cleaning mechanisms, and the ability to remove ash or deposits should be taken into account. - Manufacturer Reputation and Support:

Choosing a reputable and reliable manufacturer is crucial when selecting a boiler superheater. Buyers should research the manufacturer’s track record, expertise in superheater design and manufacturing, and their ability to provide technical support and assistance when needed. It is recommended to seek recommendations, read reviews, and evaluate the manufacturer’s customer service and after-sales support.

By considering these key factors, buyers can make well-informed decisions when selecting the right boiler superheater. Conducting a thorough evaluation of steam parameters, boiler type, material selection, configuration, maintenance requirements, and manufacturer reputation ensures that the chosen superheater will seamlessly integrate with the boiler system, deliver optimal performance, and provide long-term reliability.

Superheaters and Emissions Reduction: Environmental Benefits for Buyers

In today’s era of heightened environmental consciousness, reducing emissions and promoting sustainability are critical goals for industries across the globe. Boiler superheaters play a significant role in achieving these objectives by contributing to emissions reduction and environmental protection. In this section, we will explore the environmental benefits that boiler superheaters offer to buyers.

Improved Combustion Efficiency

Superheaters enhance the overall combustion efficiency of boiler systems, resulting in reduced fuel consumption and lower emissions. By superheating the steam, the combustion process becomes more efficient, leading to better fuel utilization and reduced waste. This translates into fewer greenhouse gas emissions, including carbon dioxide (CO2), nitrogen oxides (NOx), and sulfur oxides (SOx), which are major contributors to air pollution and climate change.

Lower Fuel Consumption

Boiler superheaters maximize the energy extraction from the fuel source, allowing for higher levels of energy efficiency. As a result, less fuel is required to generate the desired amount of superheated steam. By reducing fuel consumption, superheaters contribute to significant cost savings for buyers while simultaneously reducing the carbon footprint associated with energy production.

Reduced Particulate Matter

Superheaters also play a role in minimizing particulate matter emissions. The superheating process helps remove moisture from the steam, resulting in drier and cleaner steam supply to industrial processes. This reduces the formation of particulate matter, such as ash, soot, and other solid particles that can contribute to air pollution and health hazards.

Integration with Emission Control Systems

Boiler superheaters can be integrated with emission control systems, such as selective catalytic reduction (SCR) or flue gas desulfurization (FGD) units. These systems work in conjunction with superheaters to further reduce emissions of pollutants, such as nitrogen oxides (NOx) and sulfur dioxide (SO2). The integration of superheaters with these technologies enhances the overall environmental performance of boiler systems and helps meet stringent emission regulations.

Promotion of Renewable Energy

Superheaters also support the integration of renewable energy sources into boiler systems. By superheating steam generated from renewable energy sources, such as biomass or solar thermal energy, buyers can further enhance the environmental benefits of their operations. This helps reduce dependence on fossil fuels and contributes to a more sustainable and clean energy future.

By investing in boiler superheaters, buyers demonstrate their commitment to environmental stewardship and sustainability. These devices provide tangible environmental benefits by improving combustion efficiency, lowering fuel consumption, reducing emissions of pollutants, minimizing particulate matter, and supporting the integration of renewable energy sources. Moreover, the environmental advantages of superheaters often align with regulatory requirements and can position buyers as responsible industry leaders.

Case Studies: Real-Life Examples of Boiler Superheaters’ Performance Enhancement

To truly understand the impact and benefits of boiler superheaters, let’s explore real-life case studies where their implementation has led to significant performance enhancements and operational improvements. These examples highlight the tangible results achieved by integrating boiler superheaters into various industrial settings.

| Project Name | Product(s) Name |

| USA Covanta Energy/Onandaga Power Plant | Waste-to-energy boiler superheater |

| Sudan1#, 3# Furnace | Economizer, superheater |

| Hongkong Nanya Power Plant | Water wall, superheater(HR3C/TP347HFG/T91) |

| Australia ALSTOM(Prony Project) | Superheater |

By studying these real-life examples, buyers can gain valuable insights into the potential benefits and applications of boiler superheaters within their own industry. These case studies serve as inspiration and motivation for businesses seeking to optimize their boiler systems, enhance their operational performance, and contribute to a greener future.

Comparing Traditional Boilers to Superheated Boiler Systems

Traditional boilers have been widely used for decades, providing heat and steam for various industrial applications. However, as technology advances and the need for higher efficiency and performance grows, superheated boiler systems have emerged as a compelling alternative. In this section, we will compare traditional boilers to superheated boiler systems, highlighting the key differences and advantages that the latter offers.

Steam Quality:

One of the significant differentiating factors between traditional boilers and superheated boiler systems is steam quality. Traditional boilers produce saturated steam, which contains a certain amount of moisture. On the other hand, superheated boiler systems generate dry and superheated steam, with no moisture content. This dry steam ensures precise control over temperature and delivers consistent heat transfer, resulting in improved product quality, reduced condensation-related issues, and increased overall system efficiency.

Energy Efficiency:

Superheated boiler systems excel in energy efficiency compared to traditional boilers. By superheating the steam, energy that would otherwise be lost as latent heat in the form of condensate is utilized. This increases the overall energy efficiency of the system and reduces fuel consumption. Superheated boiler systems maximize heat transfer and improve combustion efficiency, resulting in significant energy savings and reduced operating costs for buyers.

Temperature Control and Flexibility:

Superheated boiler systems offer enhanced temperature control and flexibility compared to traditional boilers. With traditional boilers, temperature control can be challenging due to the variability of steam parameters. In contrast, superheated boiler systems allow for precise and consistent temperature control, ensuring optimal conditions for various industrial processes. The ability to deliver high-temperature and superheated steam at a stable and controlled level enables better process control and improves overall system performance.

Reduced Maintenance and Downtime:

Superheated boiler systems often require less maintenance compared to traditional boilers. Traditional boilers with internal water treatment systems are susceptible to scale and corrosion, which can lead to frequent maintenance and downtime for cleaning and repairs. In superheated boiler systems, the absence of moisture and condensed water reduces the chances of scale formation, corrosion, and related maintenance issues. This translates into increased uptime, improved productivity, and reduced maintenance costs for buyers.

Environmental Impact:

Superheated boiler systems contribute to a reduced environmental impact compared to traditional boilers. The higher efficiency and improved combustion achieved through superheating result in lower fuel consumption and reduced emissions of greenhouse gases and pollutants. The lower emissions and improved environmental performance align with sustainability goals and regulatory requirements, positioning buyers as responsible stewards of the environment.

While traditional boilers have a long-standing presence and remain suitable for certain applications, superheated boiler systems offer significant advantages in terms of steam quality, energy efficiency, temperature control, maintenance, and environmental impact. These advantages make superheated boiler systems an attractive option for buyers seeking to maximize performance, minimize operating costs, and achieve sustainability targets.

DHB Boiler’s Boiler Superheaters Parameters

Specifications

| Description | Boiler superheater |

| Material | Alloy steel, Carbon steel etc. |

| Material standard | ASTM, EN or ISO etc.Structure Type |

| Tube | Coil |

| Dimension | Customization |

| Supply ability | 1000 ton per month |

| Manufacturing process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →Bending tube→Assembly→Inspection →RT→Heat treatment (annealing)→Hydraulic pressure test→Painting→ Packaging |

| Thermal Efficiency | Around 95% |

FAQ

Here are some common questions and answers related to the topic of boiler superheaters:

Q1: What is a boiler superheater?

A1: A boiler superheater is a device that is used to further heat the steam produced by a boiler to a higher temperature, known as superheated steam. It enhances the energy transfer and overall efficiency of the boiler system.

Q2: Why is superheated steam preferred over saturated steam?

A2: Superheated steam offers several advantages over saturated steam. It has a higher energy content, improved temperature control, and better heat transfer characteristics. Superheated steam is often preferred for industrial processes that require precise temperature control and consistent heat transfer.

Q3: What are the different types of boiler superheaters?

A3: There are several types of boiler superheaters, including radiant superheaters, convective superheaters, combination superheaters, and reheaters. Each type has its own configuration and mechanism for heating the steam.

Q4: What are the benefits of using a boiler superheater?

A4: The benefits of using a boiler superheater include improved combustion efficiency, reduced fuel consumption, enhanced steam quality, precise temperature control, and lower emissions. Superheaters contribute to higher energy efficiency, cost savings, and environmental sustainability.

Q5: How do I select the right boiler superheater for my application?

A5: Selecting the right boiler superheater involves considering factors such as steam parameters, boiler type and design, material selection, superheater configuration, maintenance requirements, and the reputation of the manufacturer. Consulting with experts and conducting a thorough evaluation of your specific requirements is recommended.

Q6: What maintenance is required for boiler superheaters?

A6: Regular maintenance is essential for the proper functioning of boiler superheaters. This includes periodic inspection, cleaning of ash or deposits, and ensuring proper operation of cleaning mechanisms such as soot blowers. Following the manufacturer’s maintenance guidelines and scheduling routine maintenance checks are crucial.

Q7: Can a boiler superheater be retrofitted into an existing boiler system?

A7: In many cases, a boiler superheater can be retrofitted into an existing boiler system. However, it depends on factors such as the design and compatibility of the existing system, available space, and the specific requirements of the application. Consulting with experts and manufacturers is recommended to determine the feasibility of retrofitting a superheater.

Q8: Are there any safety considerations when using boiler superheaters?

A8: Safety considerations when using boiler superheaters include proper insulation to prevent burns, ensuring adequate water level and pressure control, and implementing safety devices such as pressure relief valves. Adhering to safety regulations, conducting regular inspections, and following recommended operating procedures are essential for safe and reliable operation.