Amidst the increasing global focus on renewable energy sources, waste-to-energy boilers have risen as a unique and promising technology, drawing significant interest. In the United States, the development of this technology is closely entwined with the evolution of waste-to-energy boilers within power plants. This piece aims to undertake an in-depth exploration through a comprehensive analysis of the viability of waste-to-energy boilers in the United States. It will scrutinize their historical progression, prevailing standards, and regulatory frameworks. The ultimate goal is to unveil the prospective role and hurdles faced by this technology within the intricate tapestry of the U.S. energy sector.

1 Historical Evolution

In the United States, the development of waste-to-energy incineration plants dates back to the 1980s. Currently, there are approximately 80 such plants with a total incineration capacity of around 8.87×105 tons per day. These facilities were predominantly constructed between 1980 and 1995 and are concentrated along the East Coast and the Great Lakes region. Additionally, there are approximately 1,300 small-scale incinerators across the country that do not generate electricity [1, 21].

However, since the implementation of the U.S. Clean Air Act in 1995, there has been a notable decline in the construction of new waste-to-energy incineration plants [1, 21]. The Clean Air Act mandates that newly built incineration facilities adhere to updated pollution emission standards, imposing constraints on the construction of new waste-to-energy plants [1, 21]. This regulatory shift has led to a period of relative stability in the development of incineration facilities.

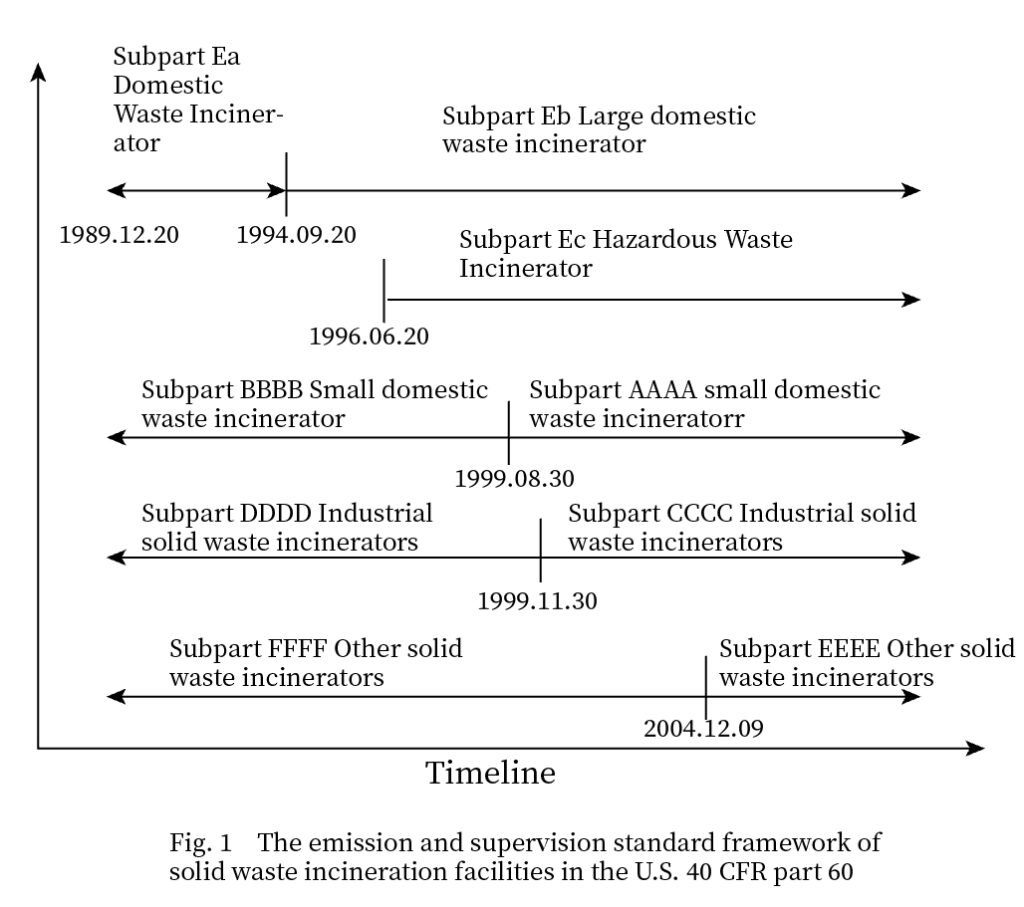

The incineration plants in the United States vary significantly in terms of scale, technological sophistication, and construction timelines, resulting in distinct differentials in emission and regulatory standards. Addressing this diversity, the “United States Code of Federal Regulations, Environmental Protection, New Source Performance Standards” (40 CFR part 60) outlines regulations for incinerators across nine subsections (see Figure 1). Among these, Ea and Eb subsections are applicable to large municipal solid waste incinerators (≥250 tons per day) constructed around September 20, 1994; whereas, BBBB and AAAA subsections apply to small municipal solid waste incinerators (35 tons per day~250 tons per day) constructed around August 30, 1999. Additionally, specific subsections cater to hazardous waste incinerators or industrial solid waste incinerators. Notably, the Eb subsection, revised in 2005, further tightened emission limits for particulate matter and heavy metals in the flue gas.

2 Current Standards

The regulations outlined in the United States Code of Federal Regulations, Environmental Protection, New Source Performance Standards (40 CFR part 60), specifically the Ea, Eb, BBBB, and AAAA subsections, are currently in effect. The emission limits within these subsections primarily differ in terms of NOx and dioxin concentrations. However, it is essential to note that several key criteria in the U.S. standards diverge from those of China or the European Union. These differences encompass parameters such as a baseline oxygen content of 7% in flue gas, a standard state defined at 20 ℃ and 1 atmosphere, the use of the U.S. short ton (1 ton ≈ 0.907 t) as the unit of weight, emission limits for conventional pollutants expressed in terms of volume concentration rather than mass concentration, dioxin emission limits specified in mass concentration rather than toxic equivalency concentration, and the computation of daily averages using geometric mean as opposed to arithmetic mean.

3 Regulatory Measures

As early as 1983, the United States established a comprehensive framework for flue gas automatic monitoring in the “United States Code of Federal Regulations, Environmental Protection, New Source Performance Standards” (40 CFR part 60). In 1990, guidelines for the automatic monitoring of incineration plants were introduced. Consequently, environmental regulation in U.S. incineration plants extensively relies on automatic monitoring methods. The Eb subsection of 40 CFR part 60 outlines requirements for automatic monitoring of flue gas in large incinerators, including: 1) automatic monitoring of CO, with compliance determined primarily through a 4-hour sliding average; 2) automatic monitoring of particulate matter and smoke opacity, with compliance determined through daily averages and 6-minute averages, respectively; 3) automatic monitoring of SO2 and NOx, with optional automatic monitoring for HCl, and compliance determined through daily averages. The AAAA subsection of 40 CFR part 60 also mandates automatic monitoring of CO, HCl, and even NOx in small incinerators. However, due to the intermittent operation of small incinerators, both the AAAA and BBBB subsections recommend that pollution monitoring generally cover three operational cycles.

Extended Analysis on the Suitability of Waste-to-Energy Boilers in the United States

Considering the multifaceted factors mentioned above, the historical proliferation of waste-to-energy boilers in the United States, marked by the construction of numerous incineration plants, has encountered a shift in trajectory due to the implementation of new regulations. The decrease in the construction of new waste-to-energy facilities is emblematic of the evolving regulatory landscape.

The unique requirements and regulatory measures embedded in U.S. standards present potential challenges for the widespread adoption of waste-to-energy boilers. These challenges stem from variations in baseline conditions, unit specifications, emission limit metrics, and calculation methodologies when compared to international norms. This regulatory intricacy necessitates a careful evaluation of compliance and adaptation for waste-to-energy boiler technologies seeking integration into the U.S. energy infrastructure.

However, amidst these challenges, there is a notable uptick in global environmental awareness, fostering a positive environment for the development and adoption of waste-to-energy boiler technologies. Positioned as a clean energy solution, waste-to-energy boilers have the potential to garner increased attention and development opportunities in the future.

The promotion and expansion of waste-to-energy boilers in the United States demand a comprehensive consideration of factors such as technological adaptability, regulatory compliance, and environmental benefits. Striking a balance between these elements will be crucial for the successful integration and sustainable growth of waste-to-energy boiler technologies within the dynamic energy landscape of the United States.

Bibliography

[1] LU J W, ZHANG S, HAI J, et al. Status and perspectives of municipal solid waste incineration in China: A comparison with developed regions[J]. Waste Management, 2017, 69(C): 170-186.

[21]PSOMOPOULOS C, BOURKA A, THEMELIS N J. Waste-to-energy: A review of the status and benefits in USA[J]. Waste Management, 2009, 29(5): 1718-1724.

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.