Embarking on an exploration of Waste to Energy Boiler applications in cold regions, this article delves into innovative strategies. From enhancing ambient temperatures to introducing advanced pretreatment systems, discover how these measures elevate efficiency and stability in waste incineration. Uncover the key insights for optimizing Waste to Energy Boilers, ensuring impactful solutions for colder climates.

As people’s living standards improve, the annual generation of domestic waste continues to rise, posing a potential threat to environmental resources if left unaddressed. Initially, waste disposal relied on methods such as burial and piling. However, with the evolution of sanitation facilities, various methods such as sanitary landfill, high-temperature composting, and incineration have gained prominence.

Incineration emerges as a pivotal waste treatment method, rendering waste harmless, reducing its volume, and conserving resources. Notably, in colder regions, incineration has become the primary approach for waste management.

Cold regions exhibit distinct climatic characteristics, characterized by prolonged winters and lower temperatures. Taking a city in Heilongjiang Province as an example, where the annual average temperature is 3.2 ℃, with January temperatures plummeting to -25.7 ℃ and July temperatures rising to 22.8 ℃, unique challenges arise. The extreme temperature fluctuations, such as the historical high of 33.68 ℃ in June 1980 and the record low of -39.5 ℃ in January 1956, impact waste management practices.

In cold climates, domestic waste tends to freeze, hindering dispersion. The frozen garbage traps water, resulting in elevated water content. For instance, in a Heilongjiang city, primary garbage exhibits a water content of 58.67%. The calorific value of the waste, which measures 5,107 kJ/kg at 15 ℃, decreases to 4,842 kJ/kg at -25.7 ℃. This lower calorific value not only influences the combustion state in incinerators but also amplifies the rate of slag thermal burn.

To address the unique challenges of winter waste management, this article advocates for the promotion of garbage fermentation measures and waste pretreatment measures. By summarizing these approaches and providing real-world engineering examples, the design of domestic waste incineration in cold regions can be tailored for optimal efficiency.

1. Promoting Measures for Domestic Garbage Fermentation in Cold Regions

In winter, the frigid temperatures prevalent in cold regions pose unique challenges to waste management. Domestic garbage, exposed to the elements, often becomes a frozen mass during extended outdoor storage. The conventional approach of relying solely on a 5 ℃ heating design temperature on the garbage unloading platform proves inadequate, as it results in prolonged thawing times and falls short of reaching the desired garbage fermentation temperature of 15 ℃. To address this issue, specific measures are imperative. This section explores strategies such as pre-heating garbage before storage, elevating ambient temperatures inside the storage area, and extending the duration of garbage storage.

1.1 Pre-heating Frozen Garbage Before Storage

When unloading frozen refuse, proactive measures can be implemented to facilitate the thawing process, either by heating the refuse using hot wastewater or incorporating heated leachate.

1.1.1 Heating Garbage with Hot Wastewater

Utilizing thermal wastewater sourced from the continuous discharge of the waste heat boiler’s steam bag proves to be a viable solution. This continuous discharge is essential for maintaining the boiler water’s rated salt content. The discharged water, usually with the highest salt content, can be directed into the waste pool during winter through a valve, or alternatively, flash steam can serve as a heat source for garbage heating. This method ensures direct heat exchange with the waste mass, offering economic advantages and higher thermal efficiency without wasting high-quality hot water or steam.

1.1.2 Using Heated Leachate for Garbage Heating

Domestic waste leachate, rich in various microorganisms, can promote garbage fermentation under specific temperature conditions. In cold regions, incorporating a leachate circulation heating device becomes a viable option. The leachate collected from the tank is circulated through a turbine pump, which generates steam for heating. This heated leachate is then sprayed onto the frozen garbage at the unloading port, effectively thawing it. This approach not only enhances heat transfer efficiency but also streamlines the leachate treatment process, contributing to the thawing of garbage in an environmentally conscious manner.

1.2 Enhancing Ambient Temperature and Prolonging Garbage Storage Time after Entry

In cold regions, the winter heating design temperature for the garbage unloading platform is 5 ℃, while the outdoor ambient temperature can plummet to below -15 ℃. To maintain the garbage pool’s negative pressure, the waste incineration plant draws primary air from the garbage pool. However, the introduction of cold air from the low outdoor temperatures disrupts the heating balance of the garbage unloading platform and diminishes the ambient temperature in the upper part of the garbage pool, adversely affecting garbage fermentation.

1.2.1 Elevating Ambient Temperature Above the Sump

To mitigate odor pollution, incineration plants extract gas from the garbage pool as combustion air, ensuring malodorous substances decompose under high-temperature conditions while maintaining a negative pressure in the garbage pool. In a Heilongjiang domestic waste incineration plant, for instance, the primary air volume required is 86,000 Nm3/h, with 30,000 Nm3/h extracted from the wet decomposition treatment workshop at 140 ℃. The remaining 56,000 Nm3/h is drawn from the external environment, encountering -25.7 ℃ temperatures in January.

By altering the primary air intake path, the plant installs two groups of primary air steam air preheaters. One group is positioned on the unloading platform, preheating the primary air to 5 ℃ and then channeling it through the pipeline to the unloading platform and the garbage pool. Simultaneously, the primary fan extracts gas heated to 5 ℃ from the refuse pond, directing it to the steam air preheater in the incineration plant. Here, the gas is further heated to 220 ℃ before being sent to the incinerator for combustion. This modification not only maintains the heating balance on the unloading platform but also elevates the ambient temperature above the refuse pond, facilitating optimal garbage fermentation conditions.

1.2.2 Augmenting Refuse Pond Capacity

Domestic garbage, characterized by its diverse composition, encompasses various types of household waste, with its water content subject to seasonal fluctuations. Regions experiencing a more extended winter season, accompanied by significant snow and ice accumulation, witness elevated water content in garbage during cold weather conditions.

During the garbage collection process, where waste is deposited into the refuse pond for storage, it undergoes a 5 to 7-day period of dumping, storage, and fermentation. At ambient temperatures, the garbage undergoes fermentation, involving extrusion and biochemical reactions that lead to the precipitation of external and internal water. This process results in a roughly 15% reduction in water content, consequently boosting the calorific value of the waste.

In cold regions, winter garbage necessitates thawing to absorb heat, and the conventional 5-7 day garbage tank exhibits limited effective volume. Therefore, enhancing the garbage tank’s capacity becomes imperative. Drawing from engineering experience, a practical approach involves reducing the number of garbage unloading gates for storing garbage, effectively increasing the storage volume of the garbage pond. This strategic modification accommodates the unique characteristics of winter waste in cold regions and ensures optimal conditions for the thawing and fermentation processes.

2. Garbage Pretreatment Measures

In addition to the previously mentioned measures aimed at enhancing heat exchange and reaching the desired fermentation temperature, the design should also consider incorporating pretreatment measures to break down frozen garbage, reduce particle size, expedite thawing, decrease water content, increase calorific value, and ensure the incinerator’s stable operation.

2.1 Integration of Additional Garbage Crushing Pretreatment System

The garbage crushing pretreatment system comprises a garbage crane feeding system, garbage conveying system, hydraulic crushing system, deodorization system, and more. Frozen garbage, transported to the hydraulic crusher via a belt or chain plate, undergoes crushing, resulting in a homogenized particle size.

Traditionally, fluidized bed Waste to Energy Boiler require a pretreatment system to ensure a fluidized state, while waste to energy boiler grate furnaces, operating through laminar combustion, do not necessitate such systems. However, in cold regions, where the goal is to expedite the melting of frozen garbage, it is advisable to introduce the crushing pretreatment system to the waste to energy boiler grate furnace.

The crusher reduces the frozen garbage to a particle size typically maintained at 200 ~ 250 mm. Subsequently, through processes like diligent dumping during garbage pool stacking, gravity extrusion, and more, the water in the garbage is encouraged to precipitate, ensuring stable combustion in the waste to energy boiler grate furnace during winter.

In a municipal waste incineration plant in Heilongjiang, two 600t/d lines were established. Prior to the implementation of the crushing pretreatment system, auxiliary fuel was required in winter to meet flue gas temperature and retention time criteria in the secondary combustion chamber. Post-installation of two hydraulic crushers, the waste particle size was reduced to 200 meters, resulting in accelerated extrusion and melting. After storage, leachate precipitation reached 8% of the total garbage amount, a significant improvement compared to almost zero precipitation before homogenization. This not only enhanced the calorific value of the garbage but also ensured stable combustion without the need for additional auxiliary fuels.

2.2 Integration of Additional Wet Waste Pretreatment System

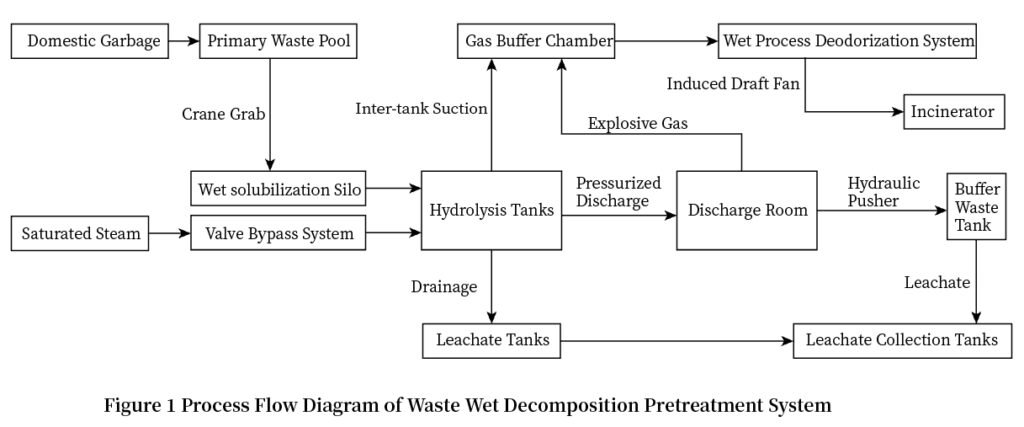

The wet decomposition pretreatment system serves as an essential mechanism directly heating the garbage, comprising a garbage crane feeding system, a wet decomposition tank for wet decomposition pretreatment, hydraulic pusher system, deodorization system, and more, as illustrated in Figure 1.

The wet decomposition pretreatment system operates by employing steam under certain pressure conditions to degrade the garbage within the sealed wet decomposition tank. This tank acts as the core system, featuring components such as a feed shutter, discharge valve, steam feed valve, steam discharge valve, level meter, and pressure gauge.

The untreated domestic garbage is fed into the wet decomposition tank through the garbage crane feeding system, equipped with an automatic measuring device and material level meter. Once a specified amount is reached, the wet decomposition tank is sealed, and saturated steam at 0.8MPa is introduced, initiating wet decomposition under elevated temperatures for 90~120 minutes. This process achieves the degradation of perishable organic waste, sterilization, dehydration, volume reduction, and conversion of easily degradable components into stable humus.

Following high-temperature wet decomposition and pressure reduction during discharge, the material undergoes transportation, flash drying, expansion, mixing, crushing, and separation processes before being sent to a buffer garbage tank through the hydraulic pusher system.

The treated garbage exhibits broken particles, homogenized size, reduced moisture content, and significantly increased calorific value. Experimental studies demonstrate a reduction in domestic garbage water content from 53.81% to below 35%, leading to a calorific value increase of approximately 3000 Kj/kg. The pressure-induced discharge process during material discharge causes an instantaneous change in pressure, forming an expanding shock wave that crushes the individual organization of the garbage, further homogenizing the particle size for improved combustion.

In cold regions where domestic garbage freezing impedes leachate precipitation and lowers the calorific value, introducing the wet decomposition pretreatment process in domestic waste incineration plants proves beneficial. This integrated approach utilizes the high calorific value of wet-decomposed garbage, optimizing the incineration process. The system effectively utilizes the steam resources of the incineration plant, enhances the calorific value of garbage, reduces pollutant emissions, and complements various components such as the garbage feeding system, garbage storage system, leachate collection system, and garbage pool deodorization system.

3. Engineering Case: Waste Incineration Plant in Heilongjiang Province

In a waste incineration plant in Heilongjiang Province, two waste to energy boiler grate furnaces with a design scale of 400t/d each were implemented. Additionally, a supplementary unloading platform steam heating system and a garbage wet pretreatment system were incorporated. The wet decomposition pretreatment system and the incineration plant feed system shared resources, requiring 0.8MPa saturated steam for the incineration plant turbine. The extracted steam underwent pumping and decompression for the incineration plant, while the wet decomposition system decompressed the steam for treating odors from the garbage pool. Simultaneously, the flash steam from the garbage pool was drawn into the incinerator by the primary fan for combustion.

To ensure incinerator stability during winter, both the unloading platform steam heating system and the garbage wet decomposition pretreatment system were activated. During operation, the unloading platform temperature remained above 5℃, maintaining heating balance, and the primary air passing through the garbage pool also exceeded 5℃, elevating the ambient temperature above the garbage.

Following processing by the wet decomposition pretreatment system, frozen garbage underwent dissolution and fragmentation, with its temperature rising to over 65℃, resulting in a precipitation of approximately 17% leachate—an evident increase compared to untreated garbage.

The processing capacity of the garbage wet decomposition pretreatment system accounted for 50% of the total garbage processing scale. The untreated garbage was mixed and fermented, achieving a calorific value matching the design requirements of the waste to energy boiler furnace. The system demonstrated the capability to handle full load evaporation capacity under optimal conditions, showcasing the effectiveness of integrated waste management strategies in ensuring stable incinerator operation.

4. Concluding Insights: Maximizing Efficiency with Waste to Energy Boilers in Cold Regions

In regions with frigid temperatures, the freezing of garbage moisture poses a significant challenge, resulting in a calorific value below 5000 Kj/kg for Waste to Energy Boilers. Without auxiliary burners, maintaining the required flue gas temperature and controlling the slag heat scorching rate within 5% becomes a formidable task. Addressing the issue of frozen garbage moisture is paramount for optimizing the calorific value.

Implementing strategic measures to enhance ambient temperatures above the waste pool and introducing an advanced wet decomposition pretreatment system has proven highly effective. These initiatives not only preserve the heating system balance on the waste unloading platform but also expedite garbage thawing, boost calorific value, and ensure stable combustion, even in the harshest cold conditions.

Given the intricacies of managing frozen garbage in cold climates and the associated high energy consumption, prudent anti-freezing measures are recommended for the waste collection and transportation system. This involves minimizing outdoor storage time, installing supplementary heating equipment at transfer stations, and promptly expediting garbage transportation out of the station. These comprehensive strategies collectively enhance Waste to Energy Boiler efficiency, fostering optimal combustion conditions while reducing overall energy consumption in cold regions.

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.