What is Boiler Header?

A boiler header, also known as a joint box, plays a crucial role in the boiler’s heating system. It’s positioned at the import and export locations of the heating surfaces within the boiler. Depending on its arrangement, we can distinguish between the import collector and the export collector. The import header box ensures that the mass is evenly distributed to the heating surface pipe system, achieving a uniform mix. On the other hand, the outlet header box combines the media from the heating surface pipe system, ensuring even mixing. The outlet header box then connects to the next level of hot surface import header box through connecting pipelines for redistribution.

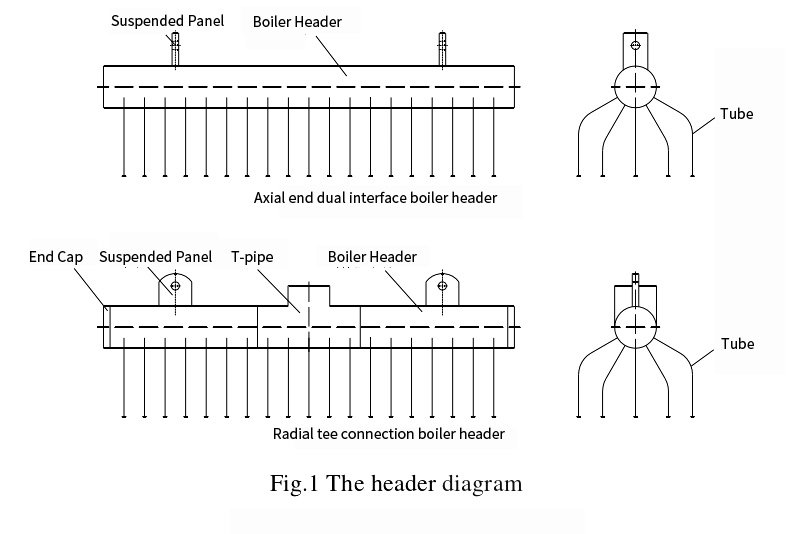

Now, when it comes to the location of these collector boxes in the pipeline, we have two types: axial end interface boxes and radial tee interface boxes. Axial end interface boxes come in two varieties, double and single connection, to ensure an even flow rate distribution across the heating surface pipe system. Radial tee interface boxes, on the other hand, typically have multiple tee or large open hole pipe joints for inlet connections and are sealed at both ends with a head or an end cap.

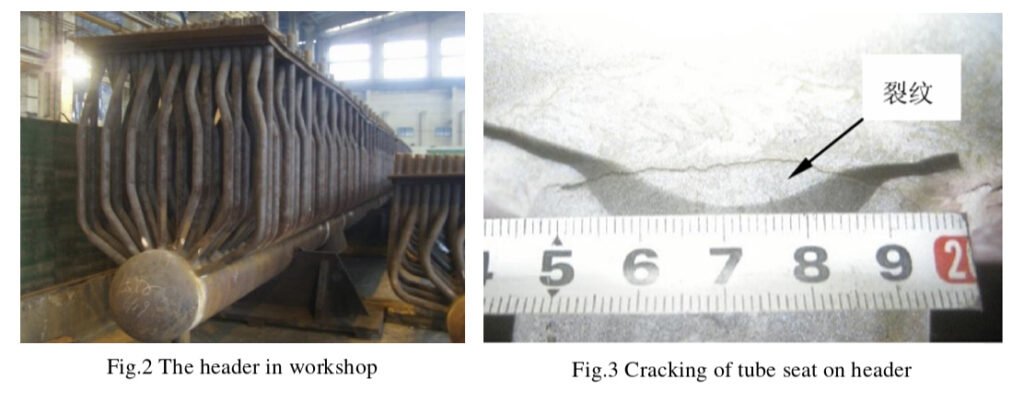

In Figure 2, you can see the manufacturing diagram of a radial tee interface box in the workshop. These collector bodies are made of seamless steel pipes and have numerous open hole receivers. These openings serve various purposes, including maintenance access, observation, and points for pressure and temperature measurements. However, it’s important to note that these openings can weaken the collector’s structural integrity to some extent, leading to concentrated stress on the inner and outer walls of these openings. Engineers must also consider the interaction between these openings. One critical area of concern in the header system is the tube seat’s position, as shown in Figure 3. Due to the constant exposure to high temperatures, pressures, and alternating loads, cracks and leaks can occur at the root of the header seat over time. Generally, radial opening receivers are used in boiler header boxes. While this configuration is favorable for the overall layout of the pipe system and welding of pipe joints, non-radial open hole receivers may be used in special cases, even though they tend to weaken the strength of the collector.

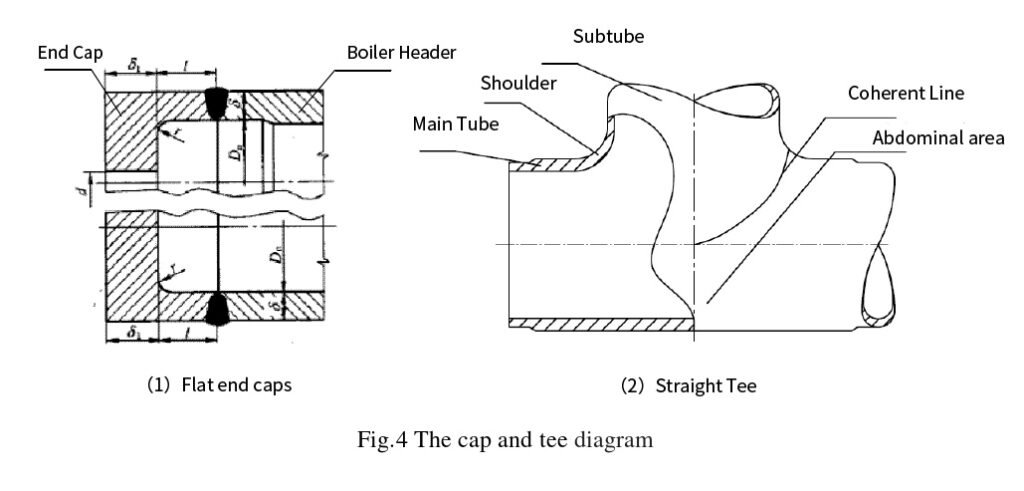

Moving on to the container system’s loaded elements, we have the end caps and tees, which share a common characteristic. Their structural stress distribution is complex and not easily expressed by analytical solutions. Stress concentration is more pronounced in these components. Figure 4 illustrates a typical flat end cap and straight tee structure.

These components are vital in the boiler system, and understanding their construction and potential stress points is crucial for ensuring the boiler’s reliability and safety.

Let’s dive into the world of boiler header loads, shall we?

When it comes to boiler headers, the loads they bear can be classified into two primary categories: mechanical loads and temperature loads. Let’s break these down further:

Mechanical Loads: Boiler header components experience a range of mechanical loads, with medium pressure being a key factor. These loads encompass more than just the force of gravity. They also encompass the weight of the header system’s metal structure, the weight of the medium being transported, the load imposed by insulation or casting materials, and the added weight of various accessories integrated into the system. Additionally, seismic loads fall under the mechanical load category. These are transient forces that can be analyzed using spectral methods to assess the dynamic response of the equipment. However, in engineering practice, it’s common to simplify this analysis using the equivalent static acceleration load method, a conservative yet effective approach.

Now, let’s shift our focus to temperature loads, which introduce a different dimension of stress to boiler headers.

It’s essential to note that the presence of temperature alone doesn’t necessarily imply the existence of thermal stress. Instead, thermal stress comes into play when there’s an uneven temperature distribution within the boiler collector system or when different materials, especially those with varying coefficients of thermal expansion, are involved. In such cases, the thermal expansion of the collector system becomes constrained, leading to the emergence of thermal stress within the system.

Let’s delve into the classification of stress in boiler headers.

Stress classification is vital, as it helps assess the impact of stress on the safety of pressurized components within the boiler header. These stresses can be categorized into primary stress, secondary stress, and peak stress, each with distinct characteristics, failure patterns, and control guidelines. You can find a detailed breakdown in Table 1. The ultimate aim of stress classification is to calibrate the different stress factors. By employing the principle of equal margin control, we use various stress intensity control values instead of a single permissible stress value. This approach is not only more scientific but also more effective in ensuring the safety of pressurized components in the boiler header.

| Stress Classification | Causes | Basic Properties | Forms of failure | Control Criteria |

| Primary stress | Balancing external loads | Non-self-limiting | Elastic or plastic failure | Criteria for plastic failure |

| Secondary stresses | Satisfying the need for coordination of its own deformation | Self-limiting | Elastic-plastic failure (stability) | Elastic-plastic failure criterion |

| Peak stresses | Effects originating from local discontinuities or localized thermal stresses | Localized, self-limiting | Fatigue failure | Criterion for cumulative fatigue damage |

When it comes to power station boiler operations, which include startup, continuous operation, and shutdown, as well as load peaking processes, it’s essential to consider how changes in medium pressure and temperature occur with varying loads. These fluctuations can lead to alterations in the stress levels of the header system, especially in areas prone to stress concentration. In many cases, these areas may enter the plastic deformation zone, necessitating an assessment of fatigue damage and an evaluation of component life.

For high-pressure boiler headers, where stress amplitudes due to cyclic loading and unloading are infrequent, typically occurring fewer than 105 times, we refer to this as low-cycle fatigue failure. In contrast, high-temperature containers also require consideration of high-temperature creep effects. It’s often necessary to examine creep damage to thoroughly assess the life expectancy of high-temperature containers. Therefore, when dealing with high-temperature and high-pressure containers, it’s crucial to account for the interplay between fatigue and creep damage, ensuring the integrity and safety of these critical components.

Let’s explore the pivotal role played by the boiler header, its positioning, structure, and key components, as well as the analysis of load characteristics and the classification of stresses based on their impact on the safety of header tank components.

Role of the Boiler Header:

The boiler header, often referred to as the joint box, is a crucial component within the boiler heating system. It serves as the hub for distributing and collecting the medium that carries heat within the boiler. Its primary function is to ensure the even distribution of this medium to the various heating surface pipes and to collect the heated medium as it returns. This balancing act is essential for efficient and safe boiler operation.

Location and Structure of the Header Box:

The header box is strategically located at the import and export positions of the heating surfaces within the boiler. Depending on its arrangement, it can be classified into two main types: the import collector and the export collector. The import collector efficiently mixes and evenly distributes the mass to the heating surface pipe system, while the export collector combines and homogenizes the medium’s temperature before routing it to the next level of hot surface import header box.

The header box’s structure typically comprises a cylindrical body made of seamless steel pipe. This body features a series of strategically placed open holes known as hole bridges, which accommodate the heating surface pipe system. Additionally, there are access points such as hand holes for maintenance and observation, as well as open pipe holders for pressure and temperature measurements. However, it’s important to note that these openings can introduce areas of potential weakness, necessitating careful design and consideration.

Characteristics of Key Header Box Components:

- End Covers: The header box features end covers that seal its ends. These components play a vital role in maintaining the integrity of the header system and preventing leaks.

- Tees: Tees are commonly used in radial tee interface boxes, facilitating the inlet connections. They allow for efficient distribution of the medium within the header system.

Analysis of Load Characteristics:

The loads imposed on the header box can be broadly categorized into mechanical loads and temperature loads. Mechanical loads primarily include medium pressure, the weight of the header system’s metal structure, the weight of the transported medium, insulation or casting material, and the added weight of system accessories. Seismic loads, though transient, also fall under mechanical loads and require careful analysis.

Stress Classification:

Stress classification is a critical aspect of assessing header tank safety. Stresses are categorized into primary stress, secondary stress, and peak stress, depending on their influence on the safety of header tank components. The goal is to determine different stress intensity control values, using the principle of equal margin control, rather than relying on a single permissible stress value. This approach offers a more scientific and effective means of ensuring the safety of the header tank’s pressurized components.

In conclusion, comprehending the role, location, structure, component characteristics, load characteristics, and stress classification of boiler header is essential for the efficient and safe operation of boiler systems. It forms the foundation for maintaining the integrity and reliability of these critical components in various industrial processes.

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.