In the quest for a greener and more sustainable future, energy efficiency has emerged as a paramount concern across industries. One critical component at the forefront of this endeavor is the boiler superheater, a vital cog in the complex machinery of energy generation. As the United States seeks innovative ways to optimize electricity production, understanding the evolving landscape of boiler superheaters becomes crucial. In this article, we embark on a journey to explore the future of boiler superheaters in the US, delving into their pivotal role, industries relying on them, government support policies, and even uncovering prominent companies that have embraced these cutting-edge technologies.

Powering the Nation: Exploring the Major Forms of Electricity Generation in the United States

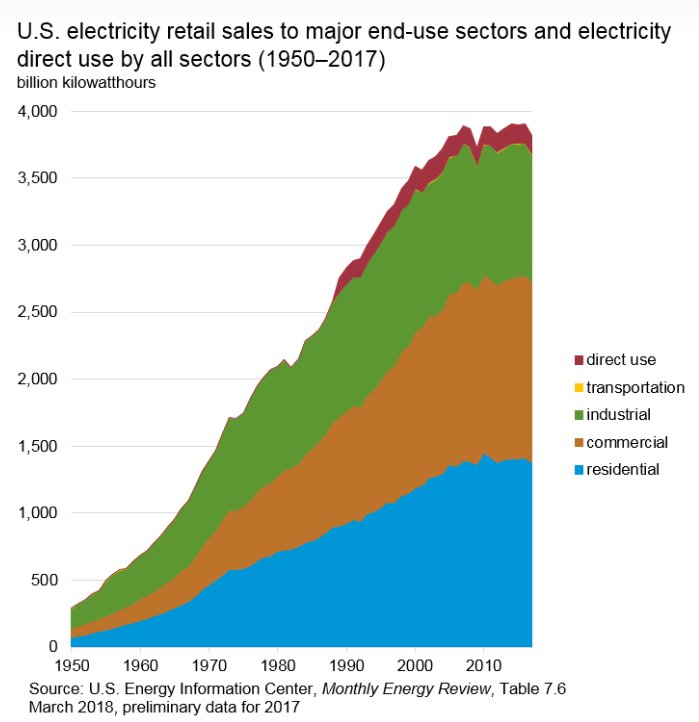

Electricity generation forms the backbone of modern society, fueling industries, homes, and technology with the power we rely on daily. As the United States strives to meet growing energy demands while addressing environmental concerns, understanding the diverse landscape of electricity generation becomes crucial. We will explore the major forms of electricity generation in the United States, delving into the key sources and their contributions to the nation’s power supply.

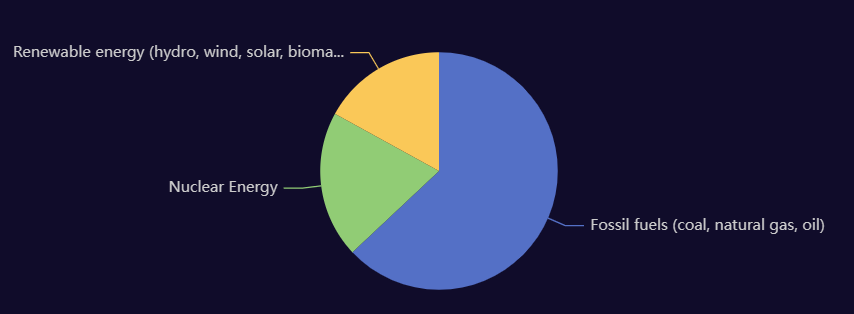

The main sources of electricity in the United States are fossil fuels (coal, natural gas and petroleum), nuclear energy and renewable energy (hydropower, wind power, solar power, biomass energy and geothermal energy) . Among them, fossil fuels are the largest source of electricity generation in the United States, accounting for about 63% of the electricity generation . Natural gas is the largest source of electricity generation in the United States, accounting for about 38% of the electricity generation in 2021 . Nuclear energy accounts for about 20% of the electricity generation in the United States . Renewable energy accounts for about 17% of the total electricity generation in the United States , of which hydropower accounts for 7%, wind power accounts for 6%, and solar power accounts for 1% .

One of the primary sources of electricity generation in the United States is fossil fuels, including coal, natural gas, and petroleum. Coal, traditionally a dominant player, has witnessed a decline in recent years due to environmental concerns and the increasing popularity of cleaner alternatives. However, it still contributes approximately 20-25% of electricity generation. Natural gas, on the other hand, has experienced a surge in popularity due to its relatively lower carbon emissions and cost-effectiveness, now providing approximately 40-45% of electricity generation. Petroleum, although a lesser contributor, accounts for less than 1% of electricity generation.

The United States has also made substantial strides in harnessing renewable energy sources for electricity generation. Solar power has experienced remarkable growth, contributing approximately 3-4% of electricity generation, with falling costs and increasing efficiency making it a viable option across the nation. Wind power has also seen remarkable expansion, providing approximately 8-9% of electricity generation, especially in areas with favorable wind resources. Hydropower, biomass, and geothermal collectively contribute approximately 7-8% of electricity generation, further reducing carbon emissions and promoting sustainability. Unclear power remains an important component of the US electricity generation portfolio, providing approximately 19-20% of electricity generation. Despite ongoing debates surrounding nuclear energy, it offers a reliable and low-carbon option for meeting the country’s power demands. The United States has a significant number of nuclear reactors, contributing substantially to the nation’s electricity supply.

The United States employs a diverse range of electricity generation sources to power the nation. While fossil fuels and nuclear power continue to contribute, there is a clear shift towards renewable energy sources. The increasing adoption of solar, wind, hydropower, biomass, and geothermal energy demonstrates a commitment to sustainable and cleaner energy production. As the nation progresses, balancing the energy mix and leveraging technological advancements will be critical for meeting future energy demands while minimizing environmental impacts.

Boilers at the Heart: Understanding the Crucial Applications of Boiler Technology in the US

Boilers are vital in the United States, powering diverse industries and critical processes. They play a crucial role in power generation, manufacturing, oil refining, healthcare, and textiles. Whether producing electricity, facilitating industrial operations, or providing steam for sterilization and textile manufacturing, boilers are at the heart of these applications. Their reliability and versatility make them indispensable components of the nation’s infrastructure, driving economic growth and sustainability.

Superheaters are typically employed in boilers that require the production of superheated steam. Superheated steam refers to steam that has been heated to a higher temperature than its saturation point at a given pressure. The addition of a superheater to a boiler allows for the generation of high-temperature, high-energy steam that offers several advantages in specific applications.

One common type of boiler that utilizes superheaters is the power plant boiler. Power plants, whether they are coal-fired, natural gas-fired, or nuclear, often incorporate superheaters to achieve higher steam temperatures and pressures. Superheated steam in power plants increases the efficiency of the turbines, leading to improved power generation and reduced fuel consumption. The superheater helps extract more energy from the steam, enhancing overall plant performance.

Industrial boilers in manufacturing processes also frequently employ superheaters. Industries such as petrochemical, chemical, and food processing require precise and high-temperature steam for various applications. Superheated steam ensures optimal temperature control, improving process efficiency and product quality. These industrial boilers with superheaters support critical processes like drying, sterilization, distillation, and other heat-intensive operations.

Superheaters are also essential in boilers used in cogeneration systems. Cogeneration, also known as combined heat and power (CHP), involves the simultaneous production of electricity and usable heat. Cogeneration systems utilize superheaters to generate high-temperature steam for power generation while extracting waste heat for heating or other industrial purposes. The superheated steam maximizes the energy extraction and utilization in these systems.

Additionally, boilers in certain specialized applications require superheaters. For instance, high-pressure boilers used in steam locomotives and marine vessels often incorporate superheaters to enhance steam performance and increase power output. Superheated steam allows for greater efficiency and power in locomotive and marine propulsion systems.

In summary, boilers that require the production of superheated steam, such as power plant boilers, industrial boilers in manufacturing processes, cogeneration systems, and specialized applications like locomotives and marine vessels, typically incorporate superheaters. The use of superheaters enables higher steam temperatures, improved efficiency, and enhanced performance in these specific boiler applications.

Unveiling the Superheater’s Role: Enhancing Efficiency and Longevity in Boiler Systems

A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. Superheated steam is used in steam turbines for electricity generation, steam engines, and in processes such as steam reforming. There are three types of superheaters: radiant, convection, and separately fired. A superheater can vary in size from a few tens of feet to several hundred feet (a few metres to some hundred metres).

From: https://en.wikipedia.org/wiki/Superheater

The incorporation of a boiler superheater can significantly enhance boiler efficiency. By transforming saturated steam into superheated steam, the superheater increases the temperature and energy content of the steam, leading to improved overall efficiency. The exact increase in boiler efficiency depends on several factors, including the specific application, operational conditions, and design of the superheater. However, studies have shown that a well-designed superheater can boost boiler efficiency by up to 10% or more, allowing for better utilization of fuel and reduced energy costs. The utilization of a boiler superheater enables the extraction of additional energy from the steam, maximizing the overall efficiency of the boiler system.

Government Support for Energy Efficiency: Policies and Initiatives Driving Superheater Adoption

The U.S. government provides several incentives to promote the adoption of energy-efficient technologies, including boiler superheaters. Here are some incentives offered by the U.S. government for boiler superheaters:

Federal Tax Credits: The government offers tax credits for businesses and industries that invest in energy-efficient technologies, including boiler superheaters. These tax credits allow for deductions or credits on eligible expenditures related to the installation or upgrade of superheaters, reducing the overall project costs.

Energy-Efficient Equipment Rebates: Some states and utility companies offer rebates or financial incentives for businesses that install energy-efficient equipment, including boiler superheaters. These programs provide financial rewards or reimbursements based on a percentage of the equipment’s cost, encouraging the adoption of energy-efficient technologies.

Energy Savings Performance Contracts (ESPCs): The government supports ESPCs, which are agreements between a federal agency and an energy service company (ESCO). Under these contracts, the ESCO installs energy-saving measures, such as boiler superheaters, and guarantees a certain level of energy savings. The ESCO is then paid from the cost savings achieved, enabling federal agencies to implement energy-efficient technologies without upfront capital costs.

Loan and Financing Programs: The government offers loan programs and financing options to support the adoption of energy-efficient technologies. These programs provide businesses with low-interest loans or favorable financing terms to invest in equipment upgrades, including boiler superheaters.

Energy Efficiency Grants and Funding: Government agencies, such as the Department of Energy (DOE) and the Environmental Protection Agency (EPA), provide grants and funding opportunities to support research, development, and implementation of energy-efficient technologies. These grants can be utilized by businesses, research institutions, and organizations involved in advancing boiler superheater technology.

It’s important to note that specific incentives and programs may vary depending on the location and the current policies of the U.S. government. Businesses and industries interested in adopting boiler superheaters are encouraged to research and consult with relevant government agencies, local utility providers, and industry associations to determine the most up-to-date incentives and funding opportunities available to them.

Leading the Way: DHB Boiler’s Superheater Solutions

DHB Boiler’s superheater solutions have gained significant traction in the United States, attracting the attention of notable companies across various industries. These companies recognize the value and benefits offered by DHB Boiler’s innovative superheater technologies. In this section, we will explore some of the leading U.S. companies that have embraced DHB Boiler’s superheater solutions, highlighting their commitment to enhancing boiler performance and efficiency.

| Project Name | Product(s) Name |

| USA Covanta Energy/Onandaga Power Plant | Waste-to-energy boiler superheater |

| Sudan1#, 3# Furnace | Economizer, superheater |

| Hongkong Nanya Power Plant | Water wall, superheater(HR3C/TP347HFG/T91) |

| Australia ALSTOM(Prony Project) | Superheater |

FAQ

Here are some common questions and answers related to boiler superheaters:

Q1: What is a boiler superheater?

A1: A boiler superheater is a component of a boiler system that is responsible for heating saturated steam to a higher temperature, known as superheated steam. It enhances the efficiency and performance of the boiler by increasing the energy content of the steam.

Q2: How does a superheater improve boiler efficiency?

A2: A superheater improves boiler efficiency by increasing the temperature and energy level of the steam. Superheated steam contains more energy compared to saturated steam, allowing for better utilization of the heat generated by the boiler. This increased efficiency translates into optimized fuel consumption and reduced energy costs.

Q3: How often do superheaters need to be replaced?

A3: The frequency of superheater replacement varies depending on factors such as the type of fuel used, operational conditions, and maintenance practices. Superheaters are designed to withstand high temperatures and pressures over an extended period. However, periodic inspection and maintenance are necessary to ensure optimal performance and identify any potential issues that may require replacement.

Q4: In which industries are boilers that require superheaters used?

A4: Boilers that require superheaters are used in various industries, including power generation, petrochemical, refining, pulp and paper, pharmaceuticals, food processing, and manufacturing. These industries rely on superheated steam for processes that demand high-temperature and high-energy steam.

Q5: Are there any government policies supporting the adoption of boiler superheaters?

A5: Yes, the government provides various incentives and programs to promote energy efficiency, including the adoption of boiler superheaters. These can include federal tax credits, grants, funding programs, and energy-saving initiatives. Additionally, energy efficiency standards and regulations encourage the use of superheaters and other energy-efficient technologies.

Q6: Which companies in the U.S. have purchased superheaters for their boilers?

A6: Several companies in the U.S. have purchased superheaters for their boilers, including notable players in industries such as manufacturing, power generation, and energy. While specific company names may vary, partnerships with reputable superheater manufacturers can provide insights into companies that have leveraged superheaters for their boiler systems.

In conclusion, the future of boiler superheaters in the US holds tremendous potential for advancing energy efficiency and sustainability. By harnessing the power of superheated steam, industries across various sectors can unlock enhanced performance, reduced operating costs, and a smaller carbon footprint. With advancements in technology and ongoing government support, the adoption of boiler superheaters is poised to grow rapidly. Embracing this transformative solution not only benefits businesses but also contributes to a greener and more sustainable future. So, take the leap and explore the possibilities of boiler superheaters today. Together, let us pave the way towards a more efficient and environmentally conscious tomorrow.