In the world of boiler operation, various accidents and failures can really throw a wrench in the works. And one of the big culprits in causing unplanned shutdowns for thermal power units is what we call the “four tube” leakage accident. It’s a major headache, folks.

Now, if you’re wondering just how much of a headache this is, let me hit you with some stats. According to the numbers, this “four tube” leakage accounts for a whopping 51% of unplanned shutdowns for these units. And within this category, superheater leakage alone makes up 27.8% of the “four tube” leaks.

So, why does this happen? There’s a laundry list of reasons for superheater tube leakage in power station boilers. We’ve got issues like poor margin selection, low furnace height, not enough steam flow, bad structural arrangements, oversized heating areas, shoddy welding, subpar materials, expansion cracks, tricky operating conditions, and good old corrosion, both inside and out, not to mention regular wear and tear.

Let me give you a more recent example. Just last December, we had a power station boiler that had a furnace tube leakage situation. The whole unit had to be shut down for a thorough check. Upon inspection, they discovered a doozy of a problem. You see, at the left side of the boiler, specifically on the rear screen superheater furnace (in the 18th row to be precise), they found a burst in a pipe section. This was right at the horizontal elbow, about 600mm up from the bottom.

This pipe section was supposed to have a diameter of φ 51mm and a thickness of 10.5mm, and the material used was S30432. To get to the bottom of the issue, the power plant needed to do some serious digging, and by that, I mean they had to cut and sample not only the problematic pipe but also three others for testing and analysis. This was all in the pursuit of figuring out what caused this furnace pipe failure. Quite a puzzle, right?

Test Analysis

Let’s dive into the nitty-gritty of this analysis. We’ve got three superheater tube samples to take a closer look at, so buckle up.

2.1 Macroscopic Examination

First things first, we had a gander at the burst tube sample to get the big picture. When we checked out the site where the rear screen superheater furnace 18-6 tube burst, we noticed that the straight section had gone through some real drama. The burst pipe got bent out of shape when it was hit by the medium pressure inside the furnace tube.

We also examined three samples from the power plant’s rear screen superheater. The first one was from the burst pipe itself, the No. 2 sample was a bit of the same pipe, but it had been replaced with new material back in 2019 (design material S30432). And the No. 3 sample came from the same pipe system when it was put into operation, made of the original material (S30432).

Now, here’s the scoop: the first tube sample had a blackened surface, was all bent out of shape, and had loads of longitudinal creep cracks. The edge of the burst pipe was significantly thinner, and you could clearly see that the outer wall had a blown platform. The minimum wall thickness was a mere 7.9mm, a far cry from the original 10.5mm. It screamed “short-term superheated burst pipe.”

As for the second and third pipe samples, they also had some visible anomalies going on.

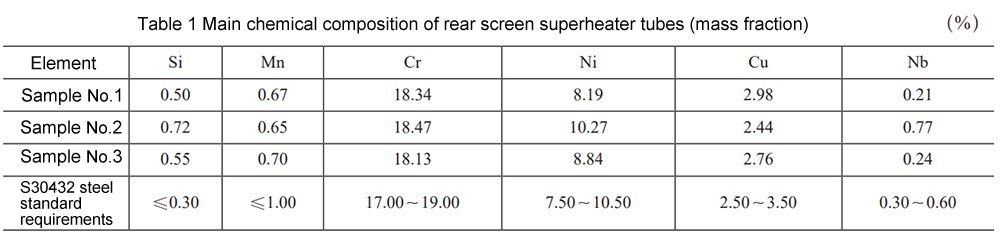

2.2 Chemical Composition Analysis

After polishing the surface of these samples, we ran a chemical composition analysis using the Hitachi VULCAN laser spectrum analyzer. Here’s what we found:

For the No. 1 and No. 3 tube samples, the silicon (Si) content was high, while the niobium (Nb) content was low.

The No. 2 tube sample had higher Si and Nb content than the standard requirements, with slightly lower copper (Cu) content. The rest of the alloying elements met the standard requirements.

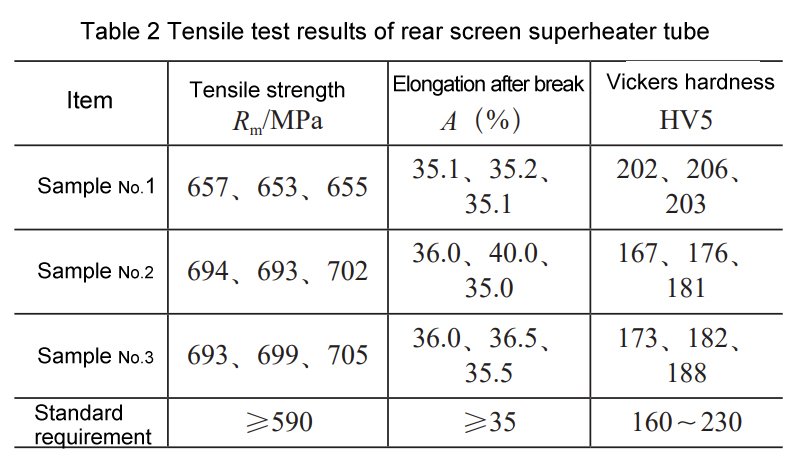

2.3 Mechanical Performance Test

After the No. 1 pipe burst, we took samples from the No. 2 and No. 3 pipes and tested them for tensile strength, elongation, and Vickers hardness. Good news – all three samples passed the GB/T 5310-2017 “high-pressure boiler seamless steel pipe” requirements.

Interestingly, the burst pipe (No. 1) had a micro-hardness value higher than the No. 2 and No. 3 tube samples. This could be linked to the rapid cooling of the tube medium during the burst, which can cause a similar hardening effect.

2.4 Metallographic Organization and Microhardness Testing

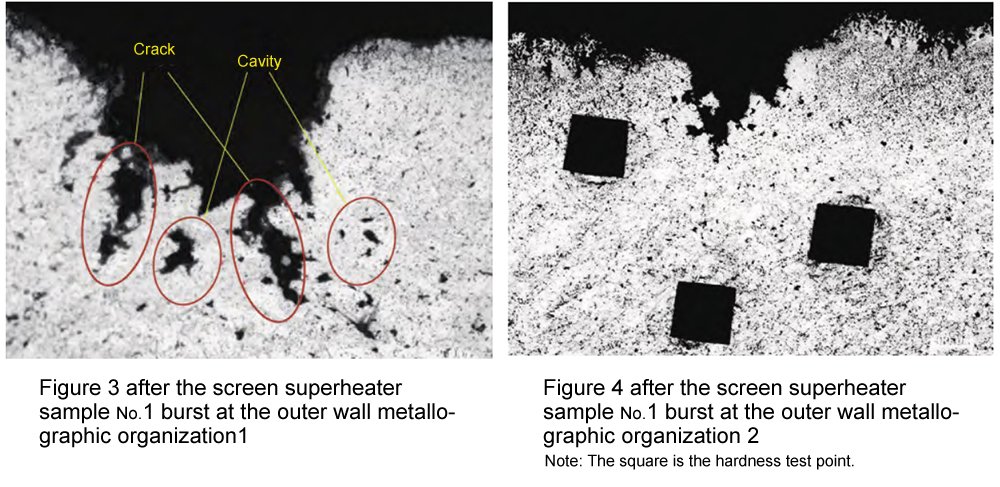

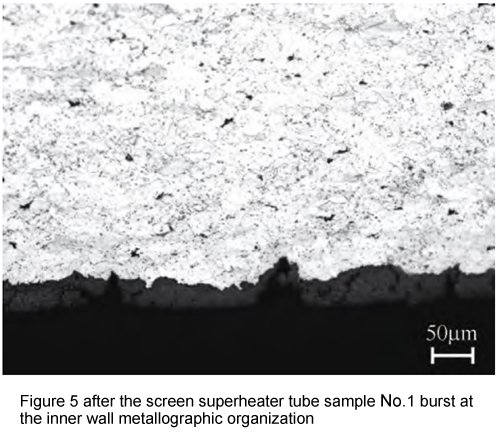

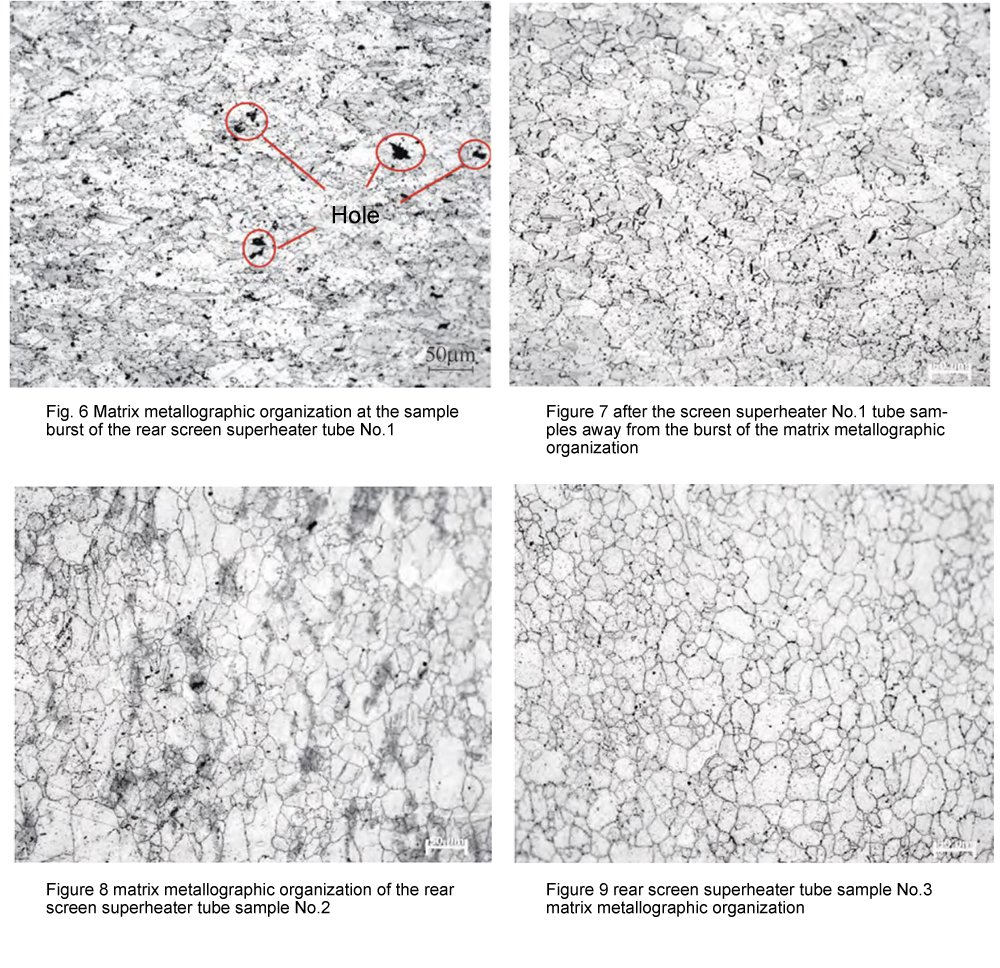

Now, for the really fine details. We looked at the metallurgical organization of these tube samples after some grinding, chemical erosion, and close observation.

For the No. 1 tube sample, the burst section showed a significant number of creep cracks and holes on both the outer and inner walls. The original austenite organization had morphed into something resembling phase transition organization. There was still a relatively intact oxide skin on the inner wall, about 50μm thick. Away from the burst part, the metallographic organization had some mild aging going on.

The No. 2 and No. 3 tube samples showed normal austenitic organization without any obvious signs of aging.

That’s the lowdown on our analysis. Quite a puzzle, isn’t it?

Conclusions and Recommendations

After thoroughly examining the test results, it’s evident that the power station boiler experienced a typical short-term superheated burst in its rear screen superheater. Here’s what we’ve gathered:

Conclusion 1: The burst pipe failed shortly after the unit was started, and signs of wall over-temperature were observed. This suggests the presence of oxide skin or welding slag, which might have obstructed the furnace tube, causing a reduction in the flow of media and eventually leading to wall over-temperature and wall thinning. These factors collectively contributed to the furnace tube’s failure.

Recommendation 1: To mitigate the risk of overheating and pipe burst triggered by the accumulation of flaking oxide skin and other foreign materials in the inner wall of the furnace tube, it is strongly advised to conduct regular inspections and cleaning of the inner wall of the furnace tube during unit maintenance. By keeping these potential blockages in check, we can help prevent such incidents in the future.

Recommendation 2: During furnace maintenance, it is crucial to prioritize the neatness and integrity of the tube rows within the furnace. Regular checks should be conducted to identify any tube rows that are out of alignment, tube rows with clips off, or anti-friction boards that have come loose. These maintenance steps are essential for preventing damage to tube rows, which can easily result in blowouts. Proactive measures like this can go a long way in ensuring the safety and efficiency of the power station boiler.

[Source] XU Qiang, ZHAO Tianhui, XIAO Zhongyan, Causes of superheater burst in power station boiler and its prevention and control

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.