Today, we set our sights on Vietnam, a country with a growing appetite for renewable energy, and embark on a journey to explore the bright and promising future of biomass boilers. In this article, we will delve into the various aspects that make biomass boilers a game-changer for boiler buyers in Vietnam.

Get ready to harness the power of biomass and discover how these remarkable boilers are reshaping the heating landscape in Vietnam. From their sustainable advantages to their exceptional efficiency, biomass boilers hold the key to a greener, more sustainable future.

Why are biomass boilers promising in Vietnam?

Let’s look at the main industries in Vietnam.

Agriculture: Agriculture is the pillar industry of Vietnam’s national economy, accounting for about 30% of the gross domestic product. Vietnam is a global important producer and exporter of economic crops such as rice, coffee, rubber, cashew, pepper, etc. Vietnam’s agriculture is mainly related to rice production, and agriculture accounted for 10.8% of GDP in 2020. Although the proportion has declined in recent years, it is still much higher than forestry (0.7%) and fisheries (3.3%).

Industry: Industry is the main driving force of Vietnam’s economic growth, and the industrial added value accounts for about 34% of GDP. Vietnam’s industry mainly includes manufacturing, construction, mining and power industries. Manufacturing is the core sector of Vietnam’s industry, mainly involving consumer electronics, textiles and clothing, furniture, automobiles and other fields. Construction is an important support for Vietnam’s economic development, mainly focusing on urbanization and infrastructure construction. Mining is a traditional industry of Vietnam, mainly including the extraction and processing of resources such as oil and gas, coal, metal minerals, etc. Power industry is a basic industry for Vietnam’s economic and social development, mainly relying on coal and hydropower generation, while also developing renewable energy sources such as solar and wind energy.

| Industry | Description | Percentage Contribution to GDP |

|---|---|---|

| Manufacturing | Electronics, textiles, footwear, furniture, automobile | 16.2% |

| Technology | Software development, e-commerce, fintech | 8.7% |

| Agriculture | Rice, coffee, seafood, cashew nuts, rubber | 15.3% |

| Tourism | Hospitality, travel services, cultural attractions | 9.6% |

| Renewable Energy | Wind power, solar power, hydropower | 1.7% |

| Retail | Supermarkets, convenience stores, e-commerce | 9.1% |

| Construction | Infrastructure development, real estate | 9.8% |

| Banking and Finance | Commercial banking, investment, insurance | 6.9% |

| Oil and Gas | Exploration, production, refining | 6.1% |

| Education | Schools, universities, vocational training | 3.6% |

With a 30% share of agriculture, the waste from crops can produce a large amount of fuel needed for biomass boilers.

With an industrial GDP growth of up to 34%, the demand for electricity from the rapidly increasing industry is bound to rise.

This creates a demand for the use of biomass boilers.

The Advantages of Biomass Boilers: A Sustainable Heating Solution for Vietnam

Biomass boilers have emerged as a sustainable heating solution, offering numerous advantages that make them a compelling choice for Vietnam’s energy landscape. As the world grapples with the challenges of climate change and the need for renewable energy sources, biomass boilers have risen to the forefront, providing a viable and eco-friendly alternative to traditional heating systems.

One of the most significant advantages of biomass boilers lies in their positive environmental impact. These boilers utilize organic materials such as wood pellets, agricultural residues, or even dedicated energy crops as fuel sources. Unlike fossil fuels, biomass is considered a renewable resource since it can be replenished through sustainable practices. By using biomass as a fuel, carbon emissions are significantly reduced, mitigating the greenhouse gas effect and contributing to the fight against global warming.

In addition to their environmental benefits, biomass boilers also offer economic advantages for Vietnam. The country possesses abundant biomass resources, including agricultural waste from the agricultural sector, forestry residues, and biomass energy crops. Harnessing these locally available resources helps reduce reliance on imported fossil fuels, providing energy security and reducing energy costs in the long run. Moreover, the growth of the biomass sector contributes to rural development, creating employment opportunities and fostering economic growth in rural communities.

The efficiency of biomass boilers is another compelling advantage. These boilers are designed to extract maximum energy from the biomass fuel, ensuring minimal waste and optimal utilization. Advanced combustion technology and heat exchangers enable biomass boilers to achieve high thermal efficiency, translating into effective and cost-efficient heating solutions for both residential and commercial applications. By maximizing fuel utilization, biomass boilers offer energy savings and a reduced carbon footprint.

Furthermore, biomass boilers are versatile and adaptable, making them suitable for a wide range of heating needs in Vietnam. Whether it’s powering central heating systems, providing hot water for domestic use, or supporting industrial processes, biomass boilers can be tailored to meet specific requirements. They can be integrated into existing heating infrastructure or serve as standalone systems, providing flexibility and scalability for different applications.

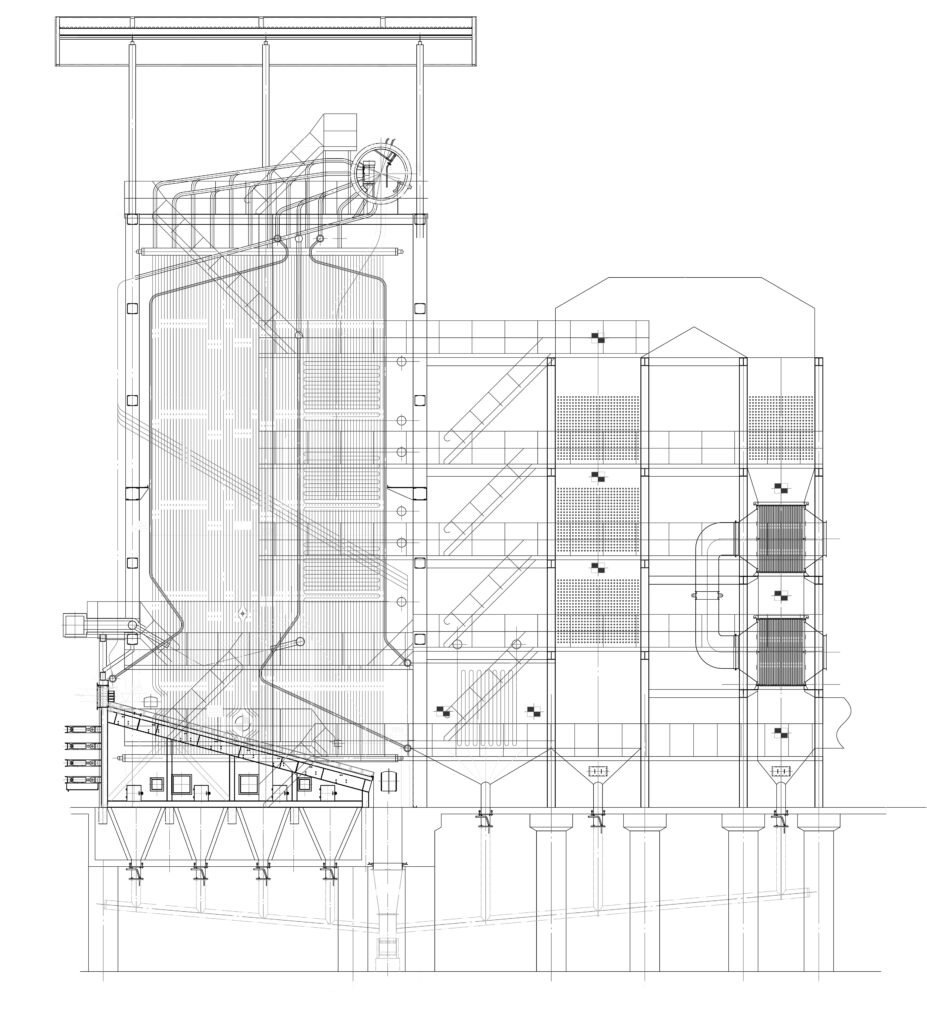

Understanding the Technology: How Biomass Boilers Work and Their Efficiency

To truly appreciate the potential of biomass boilers and make informed decisions, it is essential to understand the technology behind them and how they achieve their impressive efficiency. Biomass boilers operate on a straightforward yet efficient principle, harnessing the energy stored in organic materials to generate heat for various applications.

At the core of a biomass boiler lies the combustion chamber, where biomass fuel, such as wood pellets or agricultural residues, is introduced. In this chamber, controlled combustion takes place, releasing heat energy. The combustion process relies on a supply of air and precise regulation of oxygen levels to ensure optimal burning conditions.

The heat generated from combustion is then transferred to a heat exchanger. This component plays a crucial role in maximizing the efficiency of biomass boilers. The heat exchanger allows for the transfer of thermal energy from the hot combustion gases to the water or air used for heating purposes. As the heat exchanger absorbs the energy, the temperature of the gases is reduced, and the resulting cooled gases are expelled through the flue system.

The transfer of heat within the biomass boiler can occur through two main mechanisms: radiation and convection. Radiation involves the emission of heat energy in the form of electromagnetic waves, which are absorbed by surrounding surfaces. Convection, on the other hand, involves the movement of heated air or water, transferring heat through direct contact.

Efficiency is a key consideration when evaluating biomass boilers. The efficiency of a biomass boiler refers to the ability to extract maximum heat energy from the biomass fuel and minimize wastage. Several factors contribute to the overall efficiency of biomass boilers.

Firstly, the combustion process itself significantly impacts efficiency. Proper combustion requires the right balance of fuel and oxygen, ensuring complete burning and minimal emissions. Advanced combustion technologies, such as staged combustion or gasification, can further enhance efficiency by optimizing the combustion process and reducing particulate matter and pollutants.

Secondly, the design and construction of the heat exchanger play a vital role in the efficiency of biomass boilers. Efficient heat exchangers maximize the surface area for heat transfer, allowing for more effective transfer of thermal energy from the combustion gases to the heating medium. Additionally, the insulation surrounding the heat exchanger helps minimize heat loss and improve overall system efficiency.

Lastly, effective control systems and automation contribute to the efficiency of biomass boilers. Modern biomass boilers are equipped with advanced controls that monitor and adjust various parameters, such as fuel feed rate, air supply, and temperature. These controls optimize the combustion process, ensuring efficient fuel utilization and precise heat output.

The efficiency of biomass boilers can vary depending on factors such as the specific design, fuel type, and operating conditions. However, modern biomass boilers can achieve high thermal efficiencies, often exceeding 90%, making them a highly efficient heating solution compared to traditional fossil fuel-based boilers.

Understanding the technology and efficiency of biomass boilers provides invaluable insights for boiler buyers in Vietnam. By selecting a well-designed and efficient biomass boiler, users can enjoy optimal heat generation, reduced fuel consumption, and minimized environmental impact. With continued advancements in biomass boiler technology, the future holds even greater potential for improved efficiency and performance, further cementing biomass boilers as a sustainable heating solution for Vietnam and beyond.

Biomass Fuel Options for Boilers: Exploring the Viability in the Vietnamese Context

When it comes to biomass boilers, the fuel options available play a crucial role in their viability and performance. In Vietnam, a country blessed with abundant biomass resources, exploring the various fuel options for boilers opens up new avenues for sustainable heating solutions.

Wood pellets are one of the most commonly used biomass fuels for boilers. These pellets are produced by compressing sawdust, wood chips, or other wood residues into small, dense pellets. Wood pellets offer a high energy density and consistent quality, making them a reliable and efficient fuel source for biomass boilers. With proper storage and handling, wood pellets can be easily transported and stored, ensuring a readily available fuel supply for boiler users in Vietnam.

Agricultural residues also hold significant potential as biomass fuel for boilers in Vietnam. Rice husks, corn stalks, sugarcane bagasse, and other agricultural waste can be effectively utilized as fuel sources. These residues are often available abundantly in rural areas, where agricultural activities are prevalent. By converting these residues into fuel for biomass boilers, agricultural waste can be put to productive use, minimizing waste and reducing environmental impact.

In addition to wood pellets and agricultural residues, dedicated energy crops offer another promising fuel option for biomass boilers. Energy crops, such as miscanthus or switchgrass, are specifically grown for biomass energy purposes. These crops have fast growth rates, high energy content, and low requirements for water and fertilizer. By cultivating energy crops, Vietnam can create a sustainable and locally sourced fuel supply for boilers, reducing dependence on imported fossil fuels.

The viability of different biomass fuel options depends on several factors, including availability, cost, and environmental considerations. In Vietnam, where agriculture is a significant economic sector, utilizing agricultural residues as fuel for boilers presents a practical and cost-effective solution. By diverting agricultural waste from landfills and burning it in boilers, Vietnam can simultaneously address waste management challenges and reduce greenhouse gas emissions.

Moreover, the use of biomass fuels in boilers aligns with Vietnam’s commitment to sustainable development and reducing carbon emissions. Biomass combustion releases carbon dioxide, but the overall carbon footprint remains relatively low due to the carbon neutrality of biomass. The carbon emitted during biomass combustion is equivalent to the carbon absorbed by the biomass feedstock during growth, creating a closed carbon cycle.

As Vietnam continues to explore biomass fuel options for boilers, it is essential to consider the logistics and infrastructure required for fuel supply chains. Establishing efficient collection, processing, and distribution networks for biomass fuels ensures a consistent and reliable supply for boiler users. Collaboration between biomass suppliers, farmers, and biomass boiler manufacturers can facilitate the development of robust and sustainable fuel supply chains in Vietnam.

In conclusion, the Vietnamese context offers a rich array of biomass fuel options for boilers. From wood pellets to agricultural residues and dedicated energy crops, each fuel source presents unique advantages and considerations. By leveraging the abundant biomass resources and adopting appropriate technologies, Vietnam can tap into the potential of biomass fuels, ensuring a greener and more sustainable future for heating systems in the country.

Government Incentives and Support: Driving the Adoption of Biomass Boilers in Vietnam

Vietnam is a country with rich biomass resources, and biomass energy accounts for 73% of its total energy consumption Biomass boilers are thermal energy equipment that use agricultural waste, forestry residues, industrial waste and other biomass as fuel, which can be used for power generation or heating3 Biomass boilers have the advantages of renewable, low-carbon, clean, and energy-saving, which are of great significance for improving Vietnam’s energy structure, reducing dependence on fossil fuels, reducing greenhouse gas emissions, enhancing energy security and economic benefits.

In Vietnam, the government plays a vital role in driving the adoption of biomass boilers through a range of incentives and support mechanisms. Recognizing the significant environmental and economic benefits of biomass as a renewable energy source, the government has implemented various policies and programs to encourage businesses and homeowners to embrace biomass boilers.

One of the key government initiatives is the provision of financial incentives. These incentives come in the form of grants, subsidies, or favorable financing options that help offset the initial investment costs associated with installing boilers. By reducing the financial barrier, the government aims to make biomass boilers more accessible and attractive to a wider range of users, promoting their widespread adoption across Vietnam.

In addition to financial incentives, the government provides tax benefits to incentivize the use of biomass boilers. Tax reductions or exemptions on equipment purchases, installation, and operation costs can significantly reduce the overall cost of boiler projects. These tax incentives not only encourage businesses to invest in boilers but also contribute to the growth of the biomass industry and the development of a greener and more sustainable economy.

Furthermore, the government actively supports research and development initiatives related to biomass boilers. By funding research projects, supporting technology advancements, and facilitating knowledge sharing, the government aims to drive innovation and enhance the efficiency and performance of biomass boiler systems. This support fosters collaboration between researchers, manufacturers, and industry experts, ultimately leading to improved biomass boiler technologies tailored to the specific needs of the Vietnamese market.

The government’s role also extends to creating favorable regulatory frameworks and standards for biomass boilers. Through the establishment of clear guidelines and regulations, the government ensures the safety, quality, and reliability of boiler installations. These standards help build consumer confidence and provide assurance that biomass boilers meet specific performance criteria, ensuring optimal efficiency and minimizing environmental impact.

To promote the adoption of biomass boilers, the government engages in public awareness campaigns and educational initiatives. These efforts aim to educate the public, businesses, and policymakers about the benefits of biomass boilers, raising awareness about their potential to reduce greenhouse gas emissions, improve energy efficiency, and enhance energy security. By disseminating information and fostering a better understanding of boiler technology, the government encourages informed decision-making and facilitates the transition to sustainable heating solutions.

Government agencies also collaborate with industry stakeholders and organizations to develop training programs and capacity-building activities. These initiatives provide technical training, skills development, and knowledge transfer to technicians, installers, and service providers involved in biomass boiler projects. By equipping professionals with the necessary expertise, the government ensures the availability of a skilled workforce capable of designing, installing, operating, and maintaining biomass boiler systems effectively.

In conclusion, the government of Vietnam plays a pivotal role in driving the adoption of biomass boilers through a comprehensive range of incentives and support mechanisms. Financial incentives, tax benefits, research funding, regulatory frameworks, public awareness campaigns, and capacity-building initiatives collectively create an enabling environment for the growth of boiler installations. With the government’s steadfast commitment to promoting renewable energy solutions, biomass boilers are poised to play a significant role in Vietnam’s sustainable energy transition, contributing to reduced carbon emissions, enhanced energy security, and a greener future.

Case Studies: Successful Implementations of Biomass Boilers in Vietnam

According to these results, the successful implementations of biomass boilers in Vietnam mainly include the following aspects:

- The Vietnamese government has formulated a series of policy measures, including feed-in tariffs, carbon emission trading, subsidies, tax incentives, etc., to improve the competitiveness and attractiveness of biomass boilers, and stimulate the investment and construction of biomass boiler projects.

- Vietnam uses its abundant biomass resources, such as rice husks, bagasse, coffee grounds, etc., as fuel for biomass boilers, improving energy utilization efficiency and environmental benefits.

- Vietnam cooperates with international organizations and institutions, such as the United Nations Industrial Development Organization (UNIDO), the World Bank (WB), etc., to carry out projects such as biomass resource assessment and geospatial planning, biomass boiler technology transfer and training, biomass boiler energy efficiency standards and monitoring, etc., improving the technical level and management capacity of biomass boilers.

Some of the plants in Vietnam that use biomass boilers are:

The Quang Nam plant of HEINEKEN Vietnam, which uses a biomass boiler providing heat energy from rice husks, contributing to a 44% reduction in CO2 emissions compared to heat generated from diesel oil.

The sugarcane mills in Vietnam, which use biomass boilers to generate steam and electricity from bagasse, a by-product of sugarcane processing. Biomass CFB boilers can also use other biomass fuels such as rice husks, wood chips, etc.

The municipal and industrial co-generation power plants (CHP) in Vietnam, which use biomass boilers to produce heat and power from various types of biomass waste, such as crop residues, livestock waste, municipal waste and other organic wastes.

Join the green revolution with biomass boilers! Experience the benefits of renewable energy and contribute to a greener future for Vietnam. Take action now by requesting a quote and let us help you make the switch to sustainable heating solutions.