The boiler mentioned in this article is not the main boiler product produced by our company, but we believe it is a very valuable reference article, so we have published it here.

Jinan’s star hotel implemented an innovative modular boiler system, analyzing its efficiency and impact. Numerous studies have highlighted the correlation between the northern region’s haze issue and heating system combustion. In recent years, substantial efforts have been directed towards replacing coal-based heating with cleaner energy sources. Additionally, significant attention has been given to low-nitrogen transformations in gas heating systems, spurred by policies aimed at limiting nitrogen oxide emissions from boilers.

In light of these developments, a retrofit program was initiated for the gas boiler heating system at a hotel in Jinan City. The focus was on integrating a low-NOx Boiler Module, resulting in promising outcomes.

1. Retrofit program

1.1 Project Overview

Situated in Jinan’s Lixia District, a renowned star hotel boasts a main building of 28 floors, an annex building of 16 floors, 398 guest rooms, and a sprawling total construction area spanning 50,000 m2. Initially, the heating system relied on a horizontal internal combustion pressurized gas boiler housed on the ground floor in a 110 m2 area. Comprising 5 sets of horizontal boilers, the system exhibited low efficiency, high energy consumption, and emissions failing to meet updated atmospheric pollutant standards. With a heating heat index of 70W/m2 and a load of 3,500kW, the renovation solely targeted the heating heat source while the provision of domestic hot water remained the responsibility of the original solar + gas water heater system, falling beyond the scope of this renovation.

1.2 Background of Remodeling

In response to environmental concerns, Shandong Province issued DB 37/2376-2019 “Regional Comprehensive Emission Standards for Air Pollutants” on July 1, 2018, mandating gas boiler NOx emission concentrations in core areas to be below 50mg/m3. Simultaneously, the Environmental Protection Bureau of Lixia District in Jinan City released “Management Measures for Awarding Funds for Low-NOx Retrofitting of Gas (Oil) Boilers in Lixia District,” incentivizing gas (oil) boiler retrofits. Furthermore, the same bureau issued “Management Measures for Awarding and Subsidizing Funds for Low-NOx Retrofit of Lixia District Gas (Oil) Boilers,” urging retrofits achieving NOx emission concentrations below 30mg/m3. In alignment with these environmental policies, the hotel took proactive steps to commence gas boiler renovation.

1.3 Analysis of Retrofit Programs

1.3.1 Commonly Used Hotel Heating Heat Sources

In meeting the substantial demand for independent heating, hotels often opt for self-supplied heat sources. Presently, common forms of heat sources include horizontal water-packed boilers, vacuum boilers, lithium bromide direct-fired units, and modular gas boilers.

Horizontal water-packed fire tube boilers, while cost-effective, suffer from drawbacks such as large water capacity, high thermal inertia, and regulation lag, leading to inconsistent heating and high operating costs. They require additional flue gas treatment devices to achieve low nitrogen emissions.

Vacuum boilers, though exempt from pot inspection and boasting simple design and installation procedures, experience reduced efficiency under part-load conditions, resulting in higher operating costs. Additionally, as the vacuum degree decreases over time, efficiency decay and maintenance issues become prevalent.

Lithium bromide direct-fired units offer both summer cooling and winter heating capabilities. However, they require operation under negative pressure, similar to vacuum boilers, leading to efficiency decay issues. Furthermore, their high cost and lower summer cooling efficiency compared to electric cooling have limited their widespread adoption.

These heat source equipment types also pose challenges such as occupying large areas and incurring high boiler room construction costs.

Modular gas boilers, on the other hand, feature small single water capacities, rapid start-up, minimal thermal inertia, and high adaptability to load changes. They facilitate on-demand heating and energy savings. Designed for atmospheric pressure systems, they are exempt from inspection and employ full pre-mixed combustion with low-nitrogen burners, ensuring nitrogen oxide emissions remain below 30mg/m3 in any operating condition, supporting low-nitrogen operation.

1.3.2 Common Boiler Low-NOx Technology

Nitrogen oxides in gas boilers primarily arise from thermal and rapid types of NOx generation. Thermal NOx results from furnace temperatures exceeding 1370°C, while rapid NOx occurs due to excessive oxygen supply creating nitrogen oxides in oxygen-rich conditions.

The evolution of low-NOx technology for gas boilers has progressed through stages:

- Staged combustion involves feeding air into the boiler in two stages to achieve secondary combustion, delaying air mixing to reduce internal temperatures and suppress NOx emissions. However, primary combustion in this method often yields significant CO emissions, reducing combustion efficiency.

- Flue gas recirculation (FGR) technology lowers combustion temperatures by reintroducing part of the flue gas into the furnace chamber, inhibiting thermodynamic NOx generation. However, emission reduction efficacy fluctuates with boiler load and FGR rate, leading to unstable emissions.

- Premixed combustion technology ensures constant air-fuel ratios and complete combustion by pre-mixing air and gas before combustion. Blower-premixing technology, prevalent in Europe and the United States, involves mixing gas and air in the blower before entering low-NOx burners, uniformly distributing combustion and reducing high-temperature zones in the furnace, thus curbing NOx production.

1.3.3 Hotel Renovation Program

Given the constraints of limited space in the original boiler room and the challenges associated with increasing electricity capacity, electric thermal storage heating was deemed unfeasible. After careful analysis and considering the hotel’s requirement for low-NOx emissions, the retrofit program opted for three vertical copper-tube modular gas boilers. Each boasting a heating capacity of 1275kW, totaling 3825kW, with a thermal efficiency of ≥95%, gas consumption of 133.2m3/h, and a net weight of 1800kg. In the event of maintenance on one boiler, the remaining two can fulfill 65% of the heating capacity, aligning with requirements for cold areas.

2 Boiler Room Process System

2.1 System Composition

The boiler water system operates under atmospheric pressure, featuring three modular boilers operating in parallel with standby capabilities. The heating trunk pipe utilizes the original piping system, requiring minimal remodeling.

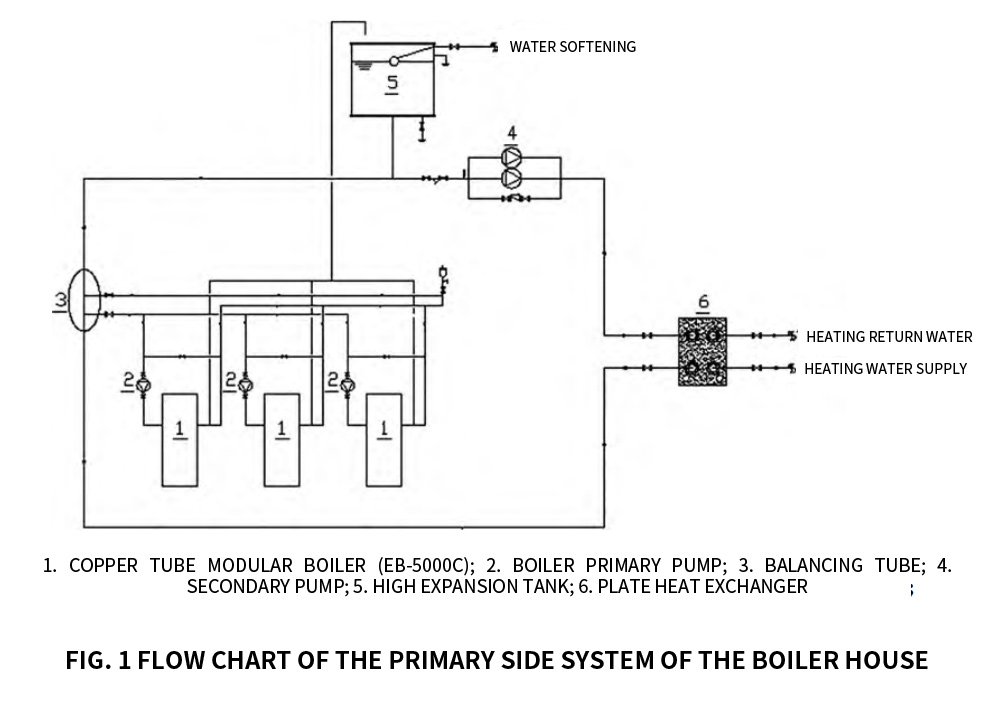

The heating system is divided into primary and secondary heat sources by plate heat exchangers. The primary side comprises modular boilers, boiler primary pumps, and secondary pumps interconnected via a balance pipe. On the secondary side, a standard heating circulation system is established.

The balance pipe serves to mix water, with design emphasis on minimizing its length, preferably less than four times the diameter of the main pipe. This design ensures nearly zero pressure drop, preventing interference between primary and secondary pumps.

Each boiler is equipped with inlet and outlet anti-condensation bypass pipes and bypass valves. These components facilitate the initial operation by bypassing water at the inlet and outlet, rapidly elevating the boiler inlet water temperature to prevent condensation resulting from low return water temperature in the furnace flue gas, thereby averting corrosion. The bypass pipe diameter matches that of the boiler inlet and outlet pipes.

The primary heat source employs an open expansion tank to maintain system pressure at a fixed point, positioned at the boiler outlet pipe and the inlet of the secondary pump. Additionally, each boiler outlet is equipped with a boiler atmospheric connecting pipe, linking to the expansion tank to ensure the boiler operates at atmospheric pressure, enhancing system safety. Makeup water for the boiler is softened. The flow of the primary side system of the boiler room is illustrated in Figure 1.

2.2 Module Boiler Secondary Pump System Analysis

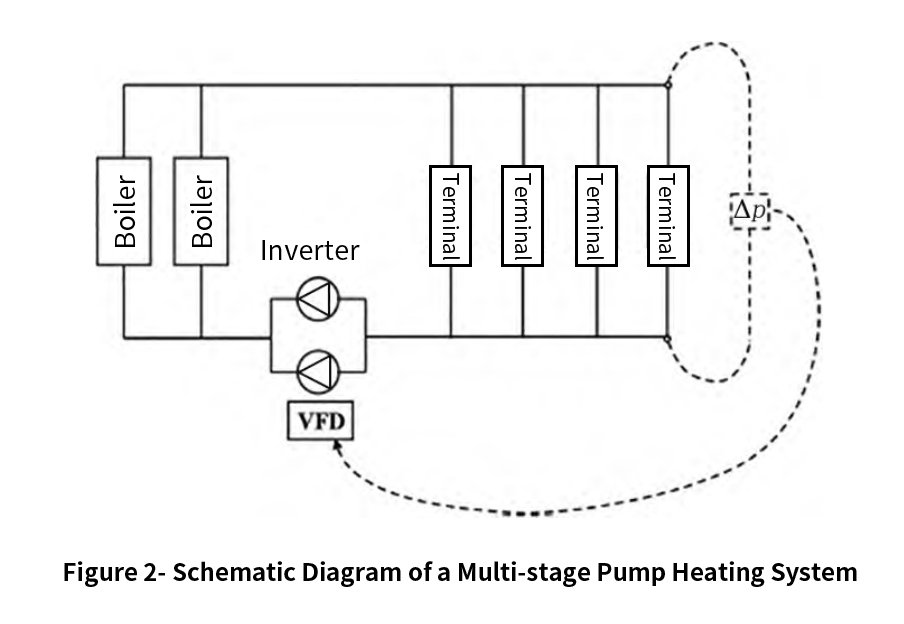

Traditional boiler designs, often featuring large water capacity fire tube boilers, typically employ a primary pump system (as depicted in Figure 2). In this setup, the boiler on the heat source side is connected in series with the end user, leading to significant thermal inertia due to the boiler’s substantial water capacity. Consequently, there is a noticeable delay in temperature response, resulting in overheating issues and decreased comfort levels, alongside considerable energy wastage.

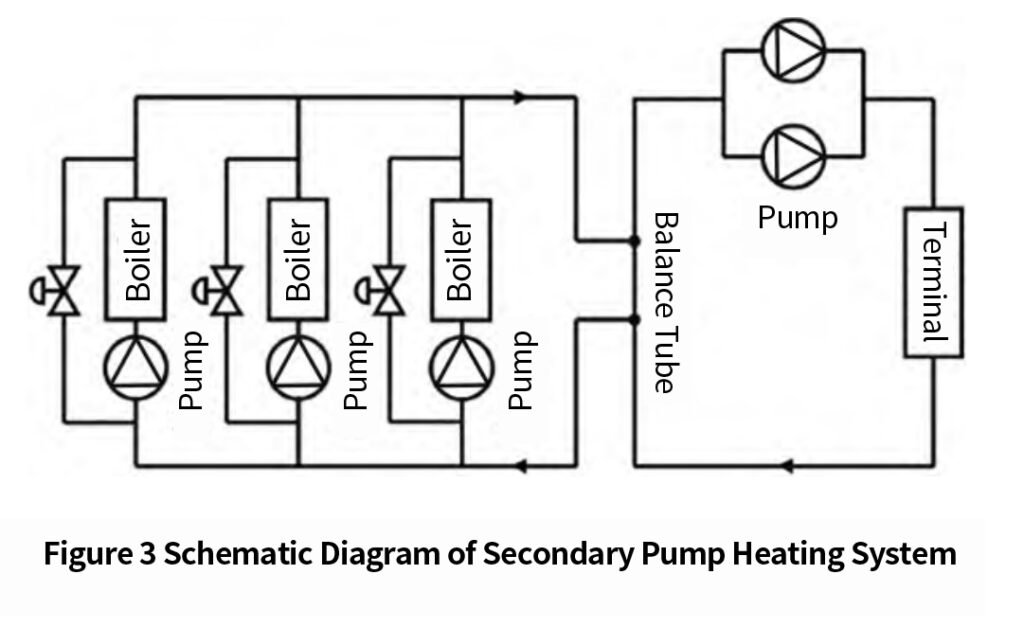

The modular gas boiler selected for the hotel’s renovation adopts a two-stage pump system (illustrated in Figure 3). With the smaller water capacity of modular boilers, their thermal inertia is reduced, enabling faster heating system warm-up. To ensure optimal boiler operation, a first-stage pump is installed at the inlet of each boiler, operating at a fixed frequency and flow rate to maintain a stable boiler flow rate on the heat source side.

On the load side, cycle power transmission is facilitated by the boiler secondary pump, which can operate at variable frequencies to better accommodate load changes. The integration of primary and secondary pumps enables independent control of the heat source side and the user side, allowing heat supply to align with demand. This setup significantly reduces system energy consumption and promotes energy savings.

2.3 Control System

The modular boiler system is equipped with an intelligent group control system, eliminating the need for additional controllers. This comprehensive control function includes boiler group control, outdoor temperature compensation, automatic rotation, remote control, and more. Moreover, it can regulate the operation of primary and secondary pumps.

For this project, three modular boilers are selected, with one designated as the system host and the other two as system slaves. The host monitors the supply/return water temperature of the three boilers for group control and regulation. When the system operating temperature falls below the set value, the host boiler is activated, while the built-in PID control system calculates the current load demand. Each boiler is sequentially activated until the load demand is met. Additionally, boilers are managed based on their cumulative running time to ensure balanced usage and prevent fatigue.

2.4 Ventilation System

Boiler combustion necessitates indoor air consumption, which can be met through natural or mechanical ventilation. For boiler rooms with modular boilers, priority is given to natural ventilation, with an effective ventilation area of 12.24cm2 per kW of input power. If natural ventilation is insufficient, mechanical ventilation should be employed, with the air volume calculated using the formula:

G = 1.33Q + 12V

Where G is the mechanical ventilation air volume (m3/h), Q is the total heat load of the boiler room (kW), and V is the volume of the boiler room (m3).

The original boiler room ventilation relies on natural ventilation, with a normally open shutter of 8m2. The renovation retains the original natural ventilation scheme unchanged. With three 1275kW module boilers requiring an effective ventilation area of 4.7m2, considering a 75% effective area coefficient of the shutters, the renovated window area should be 6.3m2 to meet combustion ventilation requirements.

2.5 Flue Gas System

The original chimney in the boiler room features a diameter of 650mm, extending along the outer wall of the podium to the roof, standing 20m above the outdoor ground level. Following the transformation, each modular boiler’s flue pipe diameter is 310mm, with the three pipes merged into a main flue with a diameter of 650mm inside the boiler room, integrated into the original chimney. Flue check valves are installed at each boiler’s flue outlet to prevent smoke cascading between boilers, while explosion-proof doors are added for pressure relief. A flue damper is also incorporated into the main flue to adjust the vertical flue’s draft force.

3 Effects of the Modification

3.1 More Flexible Heating Time

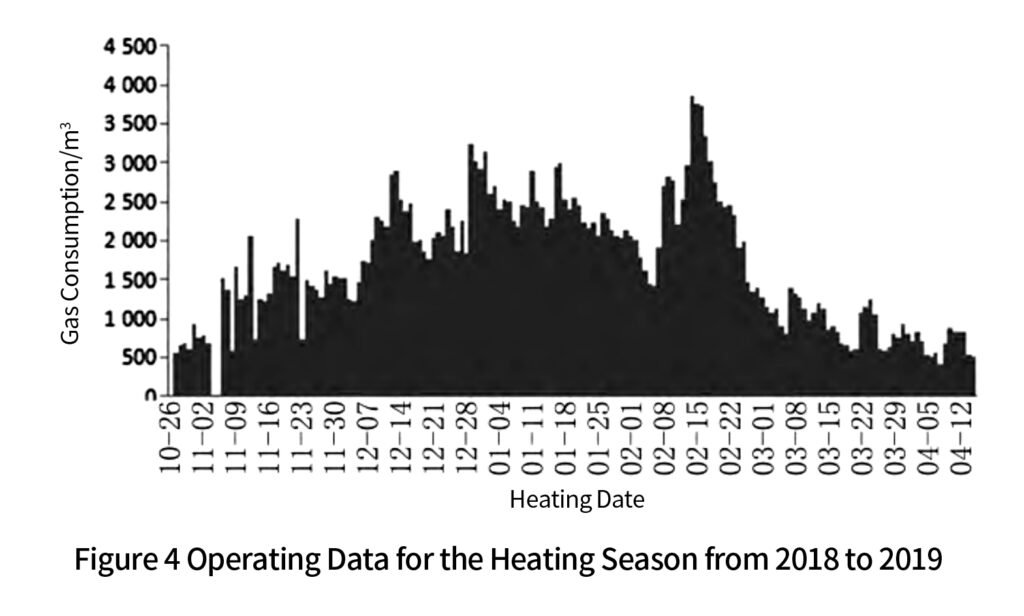

The hotel, being of high-star rating, experiences heating demands even during transitional seasons, extending its heating season beyond conventional municipal heating periods. Post-retrofitting, the automated operation of the modular boiler system allows for more flexible operation times, fully meeting the hotel’s operational needs. In the current year following the transformation, heating was extended from October 26, 2018, to April 15, 2019, nearly half a year, which is approximately two months longer than municipal central heating durations.

3.2 Substantial Savings in Operating Costs

According to hotel-provided data, the heating cost per unit area in the year after the retrofit was 22.5 yuan/m2, representing a 20% saving compared to pre-transformation costs and a remarkable 76% saving compared to municipal heating charges (based on the commercial rate of centralized heating in Jinan City, 39.6 yuan/m2). Total natural gas consumption amounted to 288,882m3, with gas consumption per unit area at 5.7m3/m2. (See Figure 4 for specific operational data.)

3.3 Convenient and Quick Transformation

Modular boilers, characterized by their vertical and compact structure, occupy minimal space. A single 1275kW modular boiler covers only 1.5m2, with a net weight of 1800kg, facilitating transportation and installation to the first basement via stairs. The post-remodeling boiler room occupies a mere 50m2, saving 60m2 of installation space. Installation is convenient and flexible, with the entire project reconstruction completed in just 15 days, minimizing disruptions to hotel operations.

3.4 Low-Nitrogen Environmental Protection, Significant Social Benefits

Post-retrofitting, tests conducted by the Jinan Lixia District Environmental Protection Bureau indicate that nitrogen oxide emissions from the modular boiler are <30 mg/m3, surpassing the requirement of <50 mg/m3 stipulated by Shandong Province’s DB37/2376-2019 “Regional Comprehensive Emission Standards for Air Pollutants.” Moreover, the retrofit meets the requirement of “Encouraging gas (oil) boiler retrofits with nitrogen oxide emissions lower than 30 mg/m3” in Lixia District, making it a demonstration project for low-NOx renovation in the district, yielding significant social benefits.

4 Conclusion

Modular boilers demonstrate high efficiency, environmental friendliness, operational flexibility, and ease of retrofitting, making them an optimal choice for hotel renovation projects of similar nature.

References:

[1] China Academy of Building Research. Heating, ventilation and air conditioning of civil buildings

Design Code for Heating, Ventilation and Air Conditioning of Civil Buildings: GB50736-2012 [S]. Beijing: China Construction Industry Press, 2012: 145

[2] China United Engineering Co. Design standard for boiler room: GB50041-2020 [S]. Beijing: China Planning Press, 2020: 23