Circulating fluidized bed boilers (CFB Boiler) represent an advanced and environmentally conscious technology for efficient coal-fired power generation. Over time, these boilers have evolved towards achieving greater scalability and higher parameterization to enhance their operational capabilities.

Development Status of Foreign Large-Scale CFB Boilers

Circulating fluidized bed (CFB) boilers, renowned for their clean and efficient coal-fired power generation capabilities, are continuously evolving towards greater dimensions and enhanced parameterization. Presently, two prominent foreign manufacturers lead the CFB boiler sector: Foster Wheeler (FW) of the United States and France’s Alstom Company.

FW holds a distinguished position as one of the foremost power station boiler manufacturers in the U.S. The company has introduced pioneering technologies such as the steam-cooled separator and the integrated return heat exchanger (INTREXTM), which collectively constitute the inaugural generation of FW’s CFB boiler innovation. In a significant milestone, FW’s first-generation technology was deployed for the U.S. JEA power station in May 2002. This marked the commissioning of the world’s earliest operational 300 MW grade CFB boilers, signifying a remarkable achievement. The boilers are equipped with three steam-cooled cyclones of 7.3 meters in diameter, each featuring external heat exchangers. Notably, these boilers employ in-furnace limestone desulphurization alongside comprehensive tail flue desulphurization through water spray-activated lime.

Integration of CFB Technologies After FW’s Merger with Ahlstrom and Evolution of Second-Generation Compact CFB Technology

Following the merger of FW with Ahlstrom in Finland in 1995, a synergistic integration of CFB technologies from both companies occurred. This collaborative effort led to the amalgamation of the steam-cooled separator, INTREXTM technology, and compact arrangement techniques, resulting in the inception of FW’s second-generation CFB technology: the compact CFB boiler.

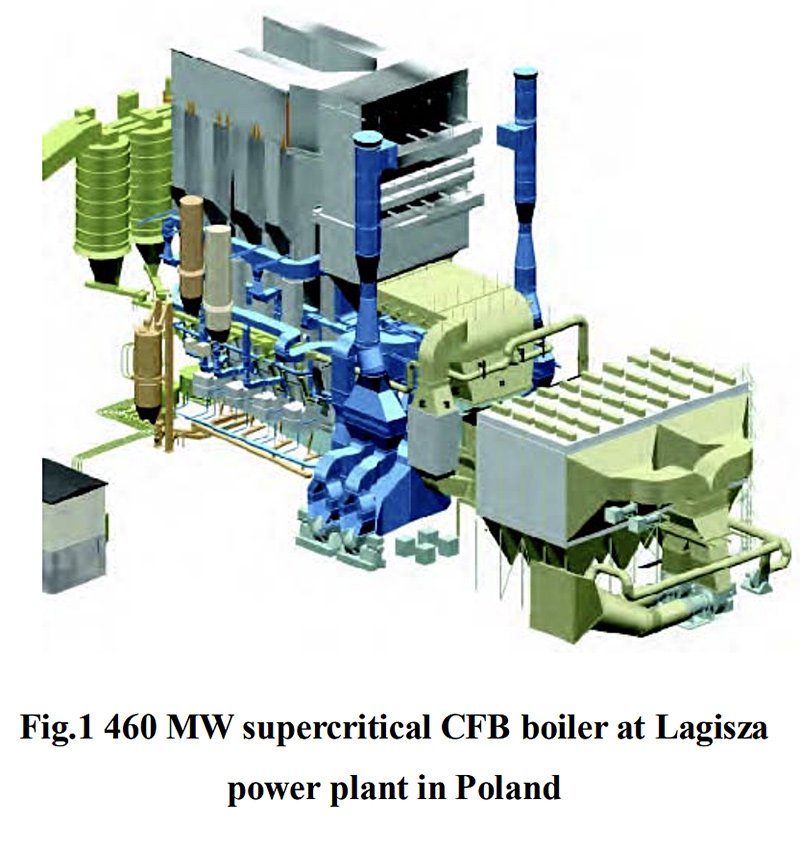

The debut of FW’s second-generation technology was witnessed in the form of three 262 MW boilers installed at the Turow Power Station II in Poland. A pivotal milestone arrived in June 2009, with the installation of the Lagisza boiler at the Lagisza Power Station in Poland. This marked the world’s first supercritical CFB boiler, achieving this feat by incorporating FW’s compact technology (refer to Fig. 1). The Lagisza Power Station’s supercritical CFB boiler boasts a formidable power generation capacity of 460 MW and impressively high steam parameters of 27.5 MPa, 560°C, and 580°C. The boiler boasts eight steam-cooled separators arranged symmetrically, encompassing a cross-sectional area of 292 m² and a towering furnace height of 48 m. The ingenious compact design of FW’s boiler enables it to operate in an ultra-critical manner.

FW’s modular approach, facilitated by its compact design, empowers the scaling up of the boiler for larger capacities. The 460 MW unit at the Lagisza Power Station serves as a magnified iteration of the 262 MW unit at Turow, thus forming the basis for FW’s designs encompassing supercritical 400 MW, 600 MW, and 800 MW plants.

Currently, FW’s portfolio of notable achievements in the realm of CFB boilers includes the 330 MW unit at the Novocherkasskaya Power Station in Russia, along with the successful realization of four 550 MW units at the Samcheok Green Power plant in Korea. Furthermore, FW’s 300 MW subcritical CFB boiler technology has been seamlessly integrated by the Wuxi Boiler Plant in China.

Alstom’s Adoption and Advancements in CFB Boiler Technology

France’s Alstom has primarily inherited the Lurgi type circulating fluidized bed (CFB) boiler technology, establishing itself as a noteworthy proponent in this field. A distinctive hallmark of Alstom’s CFB technology lies in its utilization of an external heat exchanger, a critical innovation that effectively addresses the challenge of arranging heated surfaces in the context of large-scale CFB boilers. Another pivotal aspect of Alstom’s approach is the incorporation of a trouser-legged hearth design, strategically employed to mitigate secondary air infiltration within the expansive hearth of larger boilers. This innovation not only enhances combustion efficiency but also significantly reduces pollutant emissions – both accomplishments reflective of Alstom’s engineering prowess.

A poignant illustration of Alstom’s capabilities can be observed through the 250 MW CFB boiler at the Provence Power Station in France, commissioned for operation in November 1995. This notable achievement was engineered to accommodate local high sulfur coal and oil residue, featuring steam parameters of 16.9 MPa, 567°C, and 566°C. The boiler boasts the configuration of four symmetrically arranged CFBs, with each CFB encompassing an adiabatic separator sporting a diameter of 7.4 meters. A distinctive facet of this design is the integration of an external heat exchanger (EHE) beneath each separator, underscoring Alstom’s commitment to innovative heat transfer solutions.

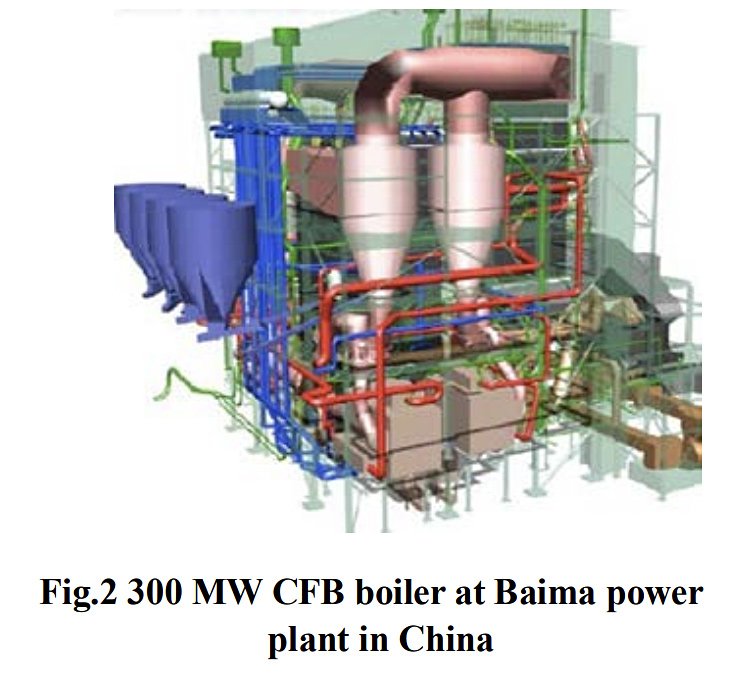

Alstom’s expertise reverberated on a global scale when, in 2003, three prominent boiler manufacturing facilities in China collaboratively introduced Alstom’s 250-350 MW class CFB technology. Subsequent to this introduction, a series of 300 MW class CFB boilers were successfully commissioned for operation, with the inaugural unit commencing service at the Sichuan Baima Power Station (refer to Figure 2).

Notably, Alstom has embarked on the conceptual design of a trailblazing 600 MW class supercritical CFB boiler. Engineered with a main steam flow rate of 1739 t/h and parameters reaching 27 MPa and 600°C, this innovation boasts a trouser-legged furnace configuration. The boiler chamber features a pant leg structure adorned with vertical tubular water-cooled walls, hosting a combustion chamber with an expansive cross-sectional area of 306 m². Adjacent to the chamber, three cyclones and external beds are symmetrically positioned. The strategic placement of heating surfaces, including superheater and reheater elements, within the external bed facilitates optimal desulfurization efficiency, realized through meticulous control of ash volume. Furthermore, this design empowers precise adjustments to the reheat steam temperature, thereby exemplifying Alstom’s commitment to engineering excellence and environmental stewardship.

Advancements in Large-Scale CFB Boiler Technology in China

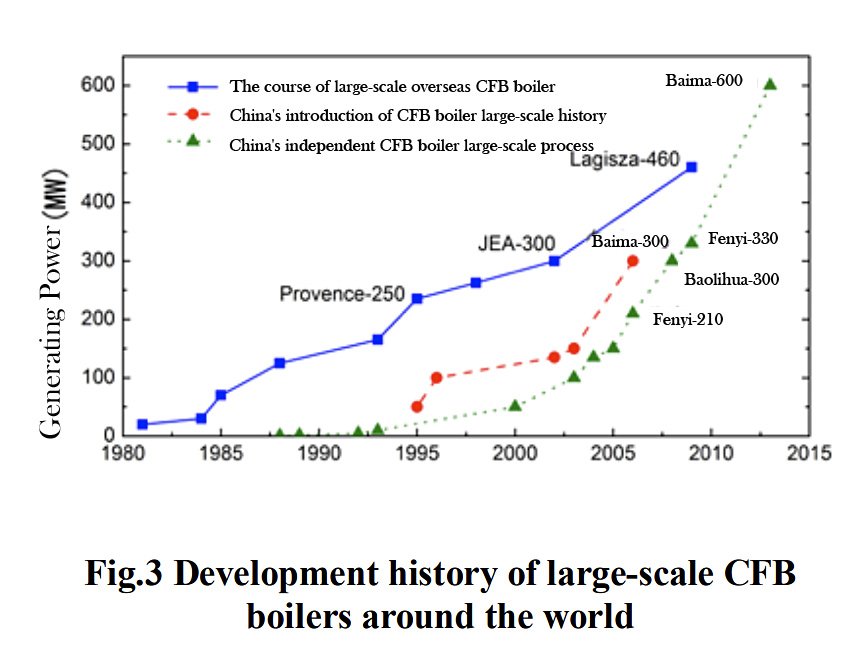

China stands at the forefront of global progress in circulating fluidized bed (CFB) boilers, showcasing unparalleled achievements in terms of both quantity and technological advancement. This remarkable position is underpinned by China’s exceptional strides in the total installed capacity, pace of innovation, and overall deployment of CFB boilers. In essence, China’s evolutionary journey within the realm of large-scale CFB boiler technology can be broadly categorized into two distinct trajectories: technology assimilation through international collaboration and independent indigenous development. The consequential historical progression of large-scale CFB boiler deployment, both domestically and internationally, is eloquently depicted in Figure 3.

In 2003, a collaborative effort among China’s three leading boiler manufacturing facilities introduced Alstom’s cutting-edge 200-350 MW-class CFB technology. This collaborative initiative marked a significant step towards harnessing advanced CFB capabilities. A pivotal demonstration project featuring a 300 MW CFB boiler was undertaken at the Sichuan Baima Power Station, overseen by the State Planning Commission and sub-contracted to Dongwu. This endeavor culminated in the operational launch of the project in April 2006. Subsequently, the trio of prominent boiler plants proceeded to consecutively inaugurate a series of 300 MW CFB boilers, effectively solidifying the technological achievements.

This heralded a transformative phase, as these leading boiler manufacturers embarked on a journey of independent research and development in the domain of large-scale CFB boilers. Leveraging a blend of knowledge assimilation and internal innovation, domestic research entities and boiler plants enthusiastically pursued autonomous advancements. The fruit of these collective efforts materialized in the form of independently developed 300 MW CFB boilers, substantiating the achievement of significant milestones in terms of proprietary intellectual property. This comprehensive endeavor equips these major boiler plants with the capability to both manufacture and supply 300 MW CFB boilers, thereby positioning China at the forefront of large-scale CFB technology.

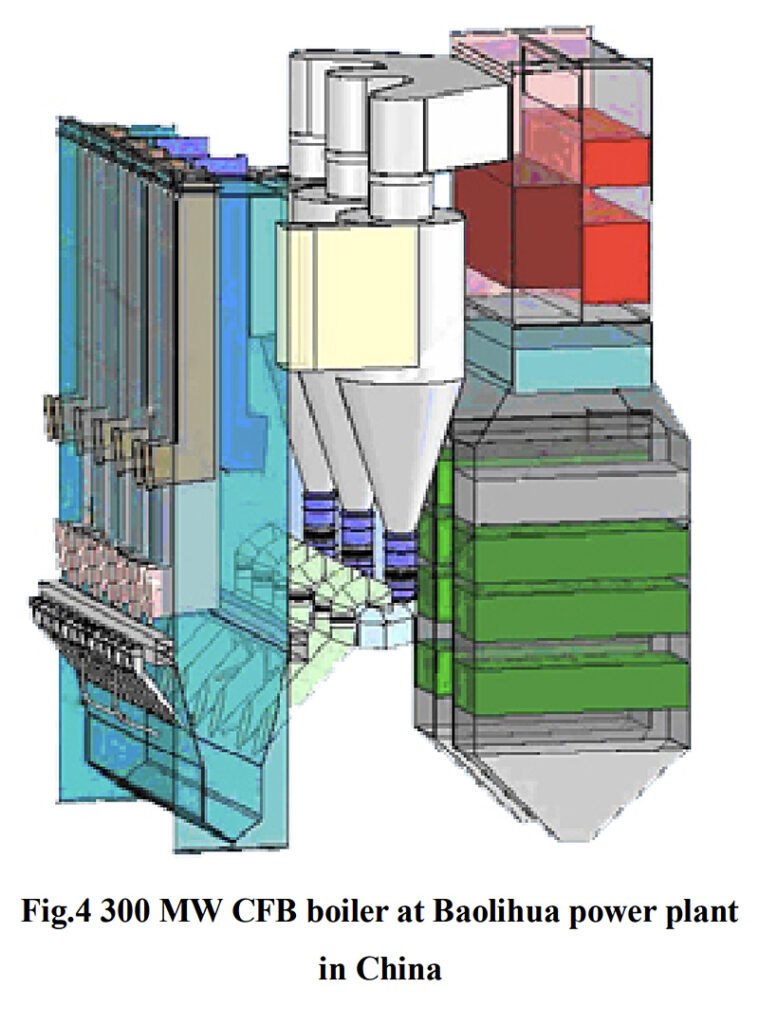

In a significant stride towards self-sufficiency, the inaugural self-developed 300 MW CFB boiler achieved operational status at the Guangdong Baolihua Power Station in June 2008. This milestone accomplishment stands as a testament to the independent design and manufacturing capabilities of the Dongfang Boiler Factory. The meticulously crafted boiler exhibits a design that integrates steam parameters of 17.45 MPa and 540°C, concurrently at inlet and outlet.

The boiler architecture is characterized by a singular furnace configuration, harmonized with a distinct M-shaped array comprising three steam-cooled cyclone separators stationed alongside the furnace periphery (refer to Figure 4). This innovative arrangement has been ingeniously devised to streamline the principal circulatory system, facilitating enhanced operational efficiency. The boiler’s design, reflective of ingenuity, forgoes the employment of an external heat exchanger. Instead, a suspended screen configuration houses both the superheater and reheater components, elegantly positioned within the upper echelons of the furnace. This design enhancement accentuates the boiler’s thermal dynamics while ensuring optimal performance.

In a collaborative endeavor, the Xi’an Institute of Thermal Engineering and Harbin Boiler Works achieved a significant milestone with the commissioning of a 330 MW CFB boiler at the Jiangxi Fenyi Power Station in January 2009. This achievement exemplified China’s concerted efforts in advancing CFB technology. The boiler’s design incorporates a singular hearth structure, complemented by an H-shaped arrangement housing four high-temperature adiabatic cyclone separators. Each separator riser is augmented with a shunt return heat exchanger, a pioneering innovation developed by the Xi’an Institute of Thermal Engineering. Positioned at the lower terminus of the separator risers, these heat exchangers facilitate the reintegration of circulating ash back into the furnace. A portion of the heat exchange surface is strategically positioned within the Circulating Cooling Heat Exchanger (CCHE), contributing to the optimization of thermal dynamics.

Furthermore, the independent endeavors of Harbin Boiler Works and Shanghai Boiler Works culminated in the successful development of their respective 300 MW CFB boilers. These achievements were realized through meticulous consideration of China’s power station operational context and a nuanced understanding of diverse furnace types. These independently developed 300 MW CFB boilers commenced operation in June and September 2010, respectively, showcasing the dedication to localized innovation.

Supported by the relevant state entities, the experience gained through the operation of this batch of 300 MW CFB boilers, endowed with proprietary intellectual property rights, played a pivotal role in narrowing the technological gap between China and foreign counterparts in terms of large-scale CFB boiler design and manufacturing capabilities. Particularly notable is the enhanced proficiency in burning inferior coal within CFB boilers. This collection of research units and boiler manufacturers has cultivated a rich repository of design expertise, which constitutes a solid foundation for the advancement of 600 MW supercritical CFB boilers within China. This robust groundwork serves as the bedrock for the forthcoming development of 600 MW supercritical CFB boilers in the nation, thus reflecting a continued commitment to cutting-edge advancements in the energy sector.

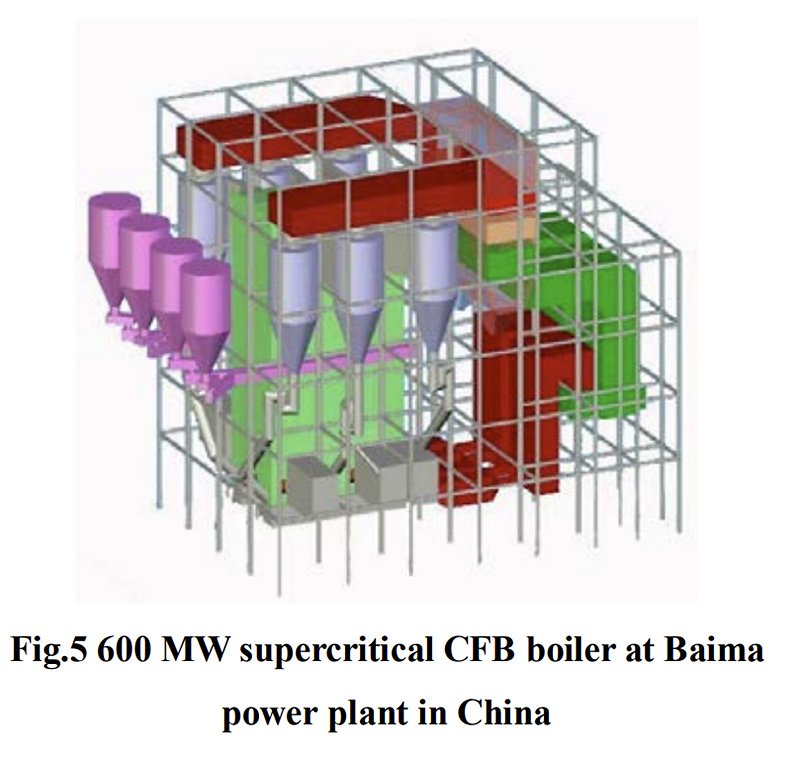

The successful commissioning of the 600 MW supercritical CFB boiler in Baima signifies that China has already possessed the technology of designing, manufacturing, installing, commissioning and operating large-scale supercritical CFB boilers.

Since the first imported 50 MW CFB boiler was put into operation in 1995, China has completed the transition from high-pressure, ultra-high-pressure, subcritical to supercritical CFB boiler technology in a short span of more than 10 years. With the accumulation of experience in the independent development of various types of 300 MW CFB boilers and the commissioning of the world’s largest supercritical 600 MW CFB boiler with its own intellectual property rights, the technology of large-scale CFB boilers has been at the forefront of the world. CFB boiler technology is already at the advanced level in the world.

The successful inauguration of the 600 MW supercritical CFB boiler at the Baima Power Station stands as a resounding testament to China’s prowess in the comprehensive domain of large-scale supercritical CFB boilers. This accomplishment signifies that China has acquired a comprehensive mastery over the entire spectrum encompassing design, manufacturing, installation, commissioning, and operation of such advanced systems.

Remarkably, China’s evolution in CFB boiler technology has been swift and impactful. The inception of the first imported 50 MW CFB boiler in 1995 marked the onset of a journey that traversed the realms of high-pressure, ultra-high-pressure, subcritical, and ultimately culminated in supercritical CFB boiler technology. This remarkable transition was achieved within a relatively condensed span of just over a decade.

Guided by an unwavering dedication to independent advancement, China’s quest was further fortified through the culmination of varied experiences in the development of diverse 300 MW CFB boiler variants. A crowning achievement emerged with the operational integration of the world’s largest supercritical 600 MW CFB boiler, a distinguished feat laden with proprietary intellectual property rights. This groundbreaking accomplishment serves as a testament to China’s commanding position at the vanguard of large-scale CFB boiler technology, a landscape characterized by global preeminence. Indeed, China’s CFB boiler technology has transcended beyond mere proficiency to an echelon of advanced mastery that asserts global leadership and innovation.

[Source] ZHOU Xing-long, XIE Jian-wen, FAN Yong-sheng, WANGBao-liang, HUANG Jun, Development And Research of Large-ScaleCirculating Fluidized Bed Boiler

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.