The multi-fuel & multi-process (aka horizontal type) circulating fluidized bed boiler is jointly developed by DHB boiler and Tsinghua University. The above-mentioned boiler is efficient, energy-saving, environmental, and stably operated medium & small circulating fluidized bed boilers. The boiler creatively extends single-stage furnaces of traditional vertical circulating fluidized bed boilers to three-zones, upgrades single-stage ash circulation to a three-stage one, and converts high-temperature material separation into a medium-temperature one.

On the one hand, the adopted technologies of the Biomass Boiler make the effective combustion space of the boiler’s furnace bigger and prolong the combustion time of fuels. Meanwhile, the structure of two-stage material circulation is beneficial to the circulation of unburned combustibles, which guarantees complete combustion of fuels and strengthens the adaptation of fuels. On the other hand, converting high-temperature separation in biomass boilers into a medium-temperature one can avoid coking of fuels with low ash fusion point in separators. This biomass boiler has outstanding emission characteristics for environmental protection, which makes clean combustion & utilization of coals come true. When being jointly applied with SNCR and FGD, this Biomass boiler can help to make the emission of solid-fuel boilers reach the emission standard of gas-fired boilers.

This biomass boiler has features such as high thermal efficiencies (real operation efficiency: 88–92%), good environmental performances (desulfurization in the furnace and low-NOx combustion), flexible fuel adaptation (suitable to different coals, biomass, and combustible solid wastes), significant energy-saving effects, stable operation processes. This biomass boiler can solve not only problems of layer-fired boilers such as low combustion efficiencies, high

NOx emissions, and unachievable desulfurization in the furnace but also problems of traditional vertical circulating fluidized bed boilers like tall furnace body and high costs. Promotion of this boiler is meaningful to the achievement of energy conservation & consumption reduction of industrial boilers and environmental protection. This boiler is suitable for hot-water or steam boilers of 6~160 t/h, whose emission standard is better than the special emission limit of gas-fired boilers (according to Emission standard of air

pollutants for boiler GB13271-2014). In this way, this biomass boiler could make ultra-clean emissions come true: dust ≤ 5mg/m3, SO2 ≤ 35 mg/m3, and NOx ≤50 mg/m3.

Main Technical Parameters

| Type of boiler | multi-fuel & multi-process circulating fluidized bed boiler |

| Capacity range of boiler | 6–160 t/h |

| Pressure range of boiler | low-temperature & low-pressure steam boilers, medium-temperature & medium-pressure steam boilers, high-temperature & high-pressure steam boilers and hot-water boilers |

| Thermal efficiencies | 88–92% |

| Suitable fuels | bituminous coals, anthracite, lignite, lean coals, coal gangue, oil shales, biomass fuels, agricultural wastes, coffee grounds, residues of traditional Chinese medicine, furfural residues |

| Range of calorific value | 1500–6000 kcal/kg |

| Furnace box temperature | 850–900 ℃ (depending on operation situations of coal combustion) |

| Inlet temperature of cyclone separator | ~500 ℃ |

| Outlet temperature of flue gas for boiler | ≤ 145 ℃ |

| Carbon-containing rate of bottom slag | < 1% |

| Structure of furnace | membraned walls |

| Heat-transfer medium | water or conduction oil |

| Initial nitrogen oxide emission | ≤ 200 mg/m3 |

| Control method of NOx | low-temperature combustion + “coupling of SNCR & SCR” |

| Desulfurization method | addition of limestone to the furnace + fine desulfurization in the tail stage |

| Dusting method | high-performance bag dust-cleaning + wet electrostatic dust-cleaning |

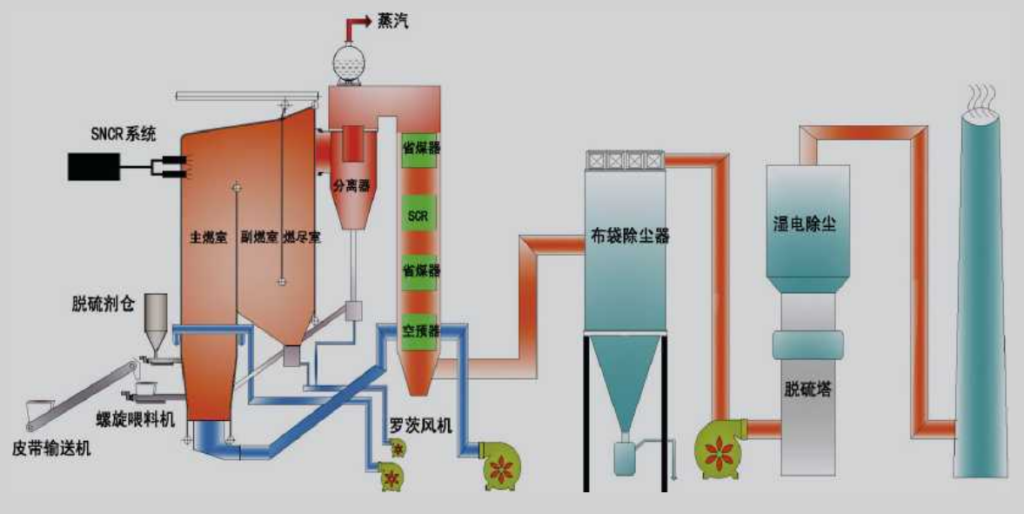

System technology processes

Primary air and secondary air are individually provided by different fans, whose ratio (of primary air to secondary air) can be adjusted according to types of fuels. The dense-phase area in the furnace belongs to turbulent beds, whose temperatures are always controlled within 850–900 ℃ (depending on operation conditions of coal combustion). In this way, low-temperature anoxic combustion conditions are generated in the dense-phase area, and formation amounts of NOx are reduced. Meanwhile, most of the heat in fuels is released in this area. After that, unburned carbon particles flow into a suspension stage and get fully burned in the oxidation zone formed by secondary air.

Produced through combustion, high-temperature flue gas with solid particles goes into a sub-combustion chamber. In the bottom area of the chamber, the temperature of flue gas decreases to about 700 ℃, and flue gas enters the ash recovery device. In the device, gas-solid separation is performed via inertial mechanical separation. Then, the separated solid particles enter into the dense-phase area of a main-combustion chamber via the ash recovery device and start combustion. Next, the high-temperature flue gas gets into a burnout chamber and goes through a second gas-solid separation in a cyclone separator when its temperature decreases to around 500 ℃. Most recycled particles after the second

separation are sent to a reinjection device. Through a feedback door, those recycled particles are sent to dense-phase areas to take part in the above-mentioned circulation again. The high-temperature flue gas separated from the cyclone separator flows through a tail shaft, whose heat is extracted by economizers and air preheaters once again. Finally, the temperature of flue gas decreases to around 145 ℃, and then flue gas is emitted into the atmosphere after a dusting stage and a desulfurization stage.

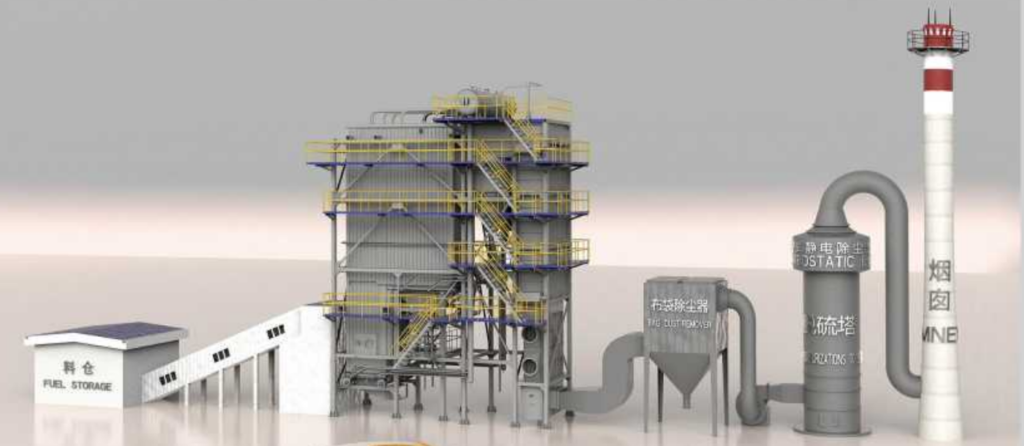

Pictures:

- Flow chart of multi-fuel & multi-process circulating fluidized bed boilers

- Project case 1 (Henan Province, P. R. China; Capacity: 13 t/h; finished in May 2014)

- Project case 2 (Sichuan Province, P. R. China; Capacity: 20 t/h; finished in August 2014)

Features of the technology

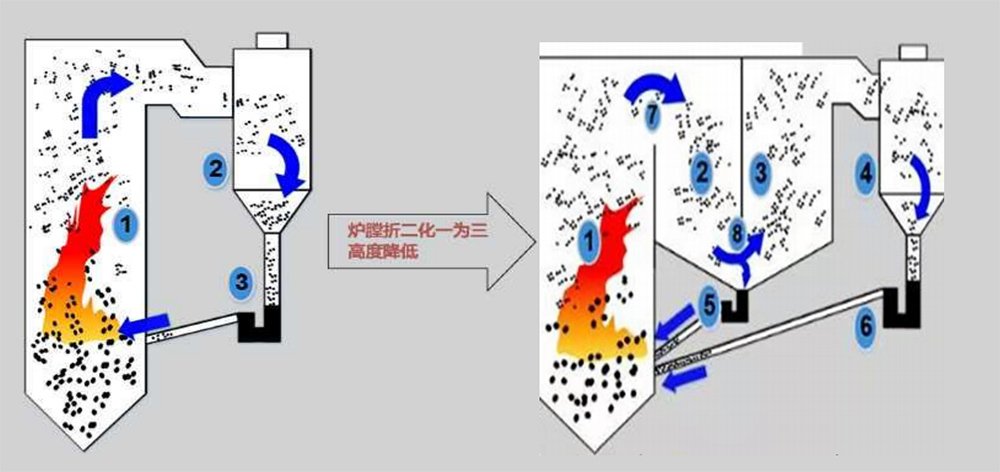

(1) Achieved miniaturization of circulating fluidized bed boilers

High efficiencies and outstanding adaptation of different fuels are features of circulating fluidized beds. However, furnace bodies of traditional circulating fluidized beds are relatively tall, which means that it is hard to shorten the furnace body (miniaturization) when making sure effective combustion suspension time.

This technology, based on the principle of circulating fluidized states, adopts a unique technical route: replacing of vertical height with vertical depth. In this way, it is achievable to ensure the miniaturization of circulating fluidized beds, shorten the height of biomass boilers, and cut down the cost of boiler production.

(2) Higher thermal efficiencies of boilers

The technology is designed with three-stage furnace and two-stage ash recovery structure. In this way, the effective combustion distance of the biomass boiler furnace increases (the effective height of the furnace is 1.6–1.8 times that of vertical circulating fluidized beds), which makes fuels fully burned and the carbon-containing ratio in bottom slag lower than 1%. Therefore, the boiler of the technology possesses high burnout rates. The three-stage furnaces, as mentioned above, are beneficial for designing heating surfaces in boilers. Promotion in both combustion organization and design of heating surfaces contributes to improving the thermal efficiencies of boilers. Meanwhile, fully-membraned walls are

adopted in the boiler, which owns advantages such as good thermal insulation and low heat loss (the rate of heat loss is less than1%). The efficiency of the biomass boiler can be higher than 88%, indicating a significant effect of energy conservation.

(3) Solved problems of alkaline-metal adhesion and ash accumulation

Some biomass or combustible solid wastes contain high contents of alkaline metals. Therefore, ash accumulation might occur on tail heating surfaces of biomass boilers owing to the low melting point of ash and strong adhesion of ash. Some technical measures are adopted in the biomass boiler design process of the technology to overcome ash accumulation and adhesion of alkaline metals. In this way, it is possible to achieve resource utilization of industrial wastes like tobacco stems:

a. A medium-temperature separation technology is adopted. The inlet temperature of flue gas in economizers of biomass boilers is about 500 ℃, lower than the adhesion & deposition temperature of alkaline metals. Thus, it is effective to avoid ash accumulation of economizers on the bundle of convection tubes.

b. Owing to three-stage furnaces adopted in the biomass boiler, radiant heating surfaces of the biomass boiler are relatively more than those of a traditional one. Correspondingly, the ratio of convective heating surfaces in design is smaller, which also effectively cuts down adhesion and deposition caused by alkaline.

metals;

c. In the process configuration, gas-pulsed soot blowers are adopted to remove ash, which is effective in removing adhesive accumulation ash.

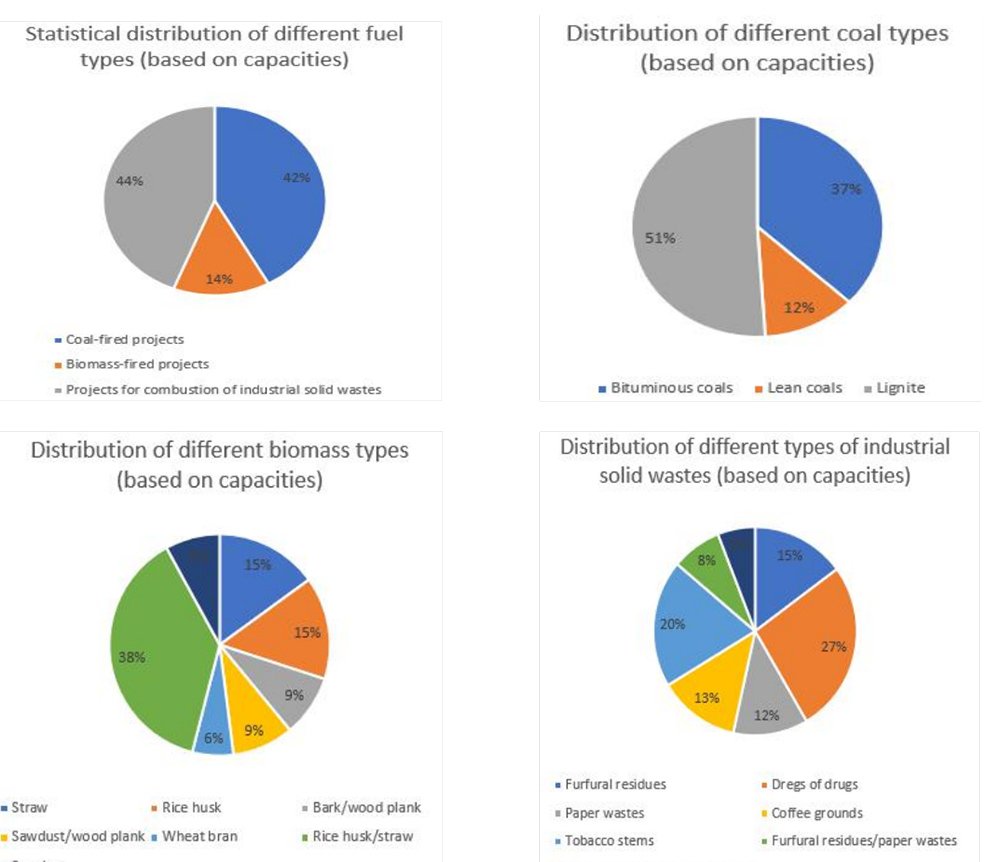

(4) Wide adaptability of fuels

(5) Solved problems of coking in boilers

Rational ratios of fuel to air are designed in this boiler. Meanwhile, a two-stage ash circulation is adopted to send low-temperature ashes (the primary ash recovery temperature is 700 ℃, and the secondary ash recovery temperature is 500 ℃) back to main-combustion chambers, which can make the combustion temperature of dense-phase areas in boilers decrease to avoid overheat of biomass boilers. The temperature of main combustion chambers is strictly controlled within 850– 950 ℃, which avoids the occurrence of coking.

(6) Solved problems of environmental protection in combustion

Bag filters are adopted in the technology, whose dusting efficiency is as high as 99.9%. In this way, the emission of dust is lower than 20 mg/m3. Moreover, bag filters belong to dry dust-cleaning methods. Thus, there is no effluent in the dusting process.

The furnace box temperature of multi-process circulating fluidized bed boilers is 850–950℃. At this temperature, the production amount of thermal NOx can be ignored. Meanwhile, graded air supply and graded fuel supply are adopted in the biomass boiler, which can restrain the conversion of nitrogen in fuels to NOx via chemical mechanisms like oxygen-deficient reduction. There is no denitration process in the biomass boiler, and the initial NOx emission is less than 200 mg/m3.

Moreover, there is an individual device of limestone addition, which can uniformly add limestone to the furnace to achieve desulfurization in the furnace. The method of “desulfurization via limestone in furnace + flue gas desulfurization (FGD) in the tail stage” can make sure low emission of SO2.

Pictures:

- High-performance bag filters

- FGD in the tail stage of biomass boilers; high-performance desulfurization towers for coal-fired boilers

Environmental Protection Route

Two-stage dusting: the first stage of dusting is performed via high-performance bag filters with slow filtration rates, whose dusting effects are good with low operation cost. The second stage of dusting is wet electrostatic precipitators, whose advantages include high dusting efficiencies, small pressure drop, easy operation process, and low energy consumption. With these advantages, wet electrostatic precipitators can make sure stable dusting effects.

Two-stage desulfurization: desulfurization via limestone in the furnace can make sure removal of 85% sulfur with low costs and high efficiencies. Fine desulfurization via alkaline solutions in the tail stage possesses advantages such as high efficiencies & stability and low costs because the total amount of removed sulfur is low.

Two-stage denitration: first of all, low-temperature combustion and multi-process combustion can make the initial amount of produced NOx low enough; secondly, the coupling process “SNCR + SCR” can make the amount of NOx emission decrease again, which has some advantages like simplicity of equipment and adaptability to variable fuels & loads owing to large high-temperature areas in horizontal circulating beds. Meanwhile, the combination of SNCR and SCR can promote each other’s strengths and avoid

each other’s weaknesses as far as different denitration processes are concerned. Moreover, SNCR and SCR are not only technically grouped together. In fact, the combination of SNCR and SCR is a newly-developed technology that simultaneously contains features such as high performance of SCR and low investment of SNCR.

Environmental Emission Index

| No. | Concentration of pollutants | Emission index of the product | Emission limits in GB13271-2014 | |

| Coal-fired boilers | Gas-fired boilers | |||

| 1 | Dust (mg/m3) | 5 | 50 | 20 |

| 2 | SO2 (mg/m3) | 35 | 300 | 50 |

| 3 | NOx (mg/m3) | 50 | 300 | 200 |

| 4 | Blackness (grade) | ≤ Ⅰ | ≤ Ⅰ | Ⅰ |

| 5 | Hg | 0.05 | 0.05 | |

Comparison of different technologies

Comparison between multi-process circulating fluidized bed boilers and traditional vertical circulating fluidized bed boilers

| No. | Items | Traditional vertical circulating fluidized bed boilers | Multi-process circulating fluidized bed boilers |

| 1 | Capacity ranges | Mostly, ≥ 35 t/h; Barely, ≤ 35 t/h | Mainly, 6–160 t/h |

| 2 | Combustion stages | One-stage furnace, short combustion time, difficult in burning lignite & biomass with high volatile contents | Three-stage furnaces, effective combustion areas being 1.6–1.8 times those of traditional vertical CFB, long combustion time, high burnout rates |

| 3 | Ash circulation | One-stage ash overflow, high carbon-containing contents in fly ash, difficult in burning coals with low ash contents | Two-stage ash overflow, low carbon-containing contents in fly ash, capable of burning coals with low ash contents |

| 4 | Thermal efficiencies | 86–90% | 88–92% |

| 5 | Separators | High-temperature separation, the inlet temperature of separators being 850– 900 ℃, short service lives, significant heat loss, presence of afterburn, coking of separators | Medium-temperature separation, the inlet temperature of separators being 500 ℃, long service lives, less heat loss, no afterburn, no coking in separators |

| 6 | Building costs | Tall boilers, high costs | Short boilers, one-layer configuration, low costs |

| 7 | Adaptability of fuels | Low adaptability to fuels with high volatile contents or low ash contents | Good adaptability to combustible & inferior fuels or fuels with high volatile contents |

Pictures:

- Schematic of a traditional vertical circulating fluidized bed

- Schematic of a multi-process circulating fluidized bed

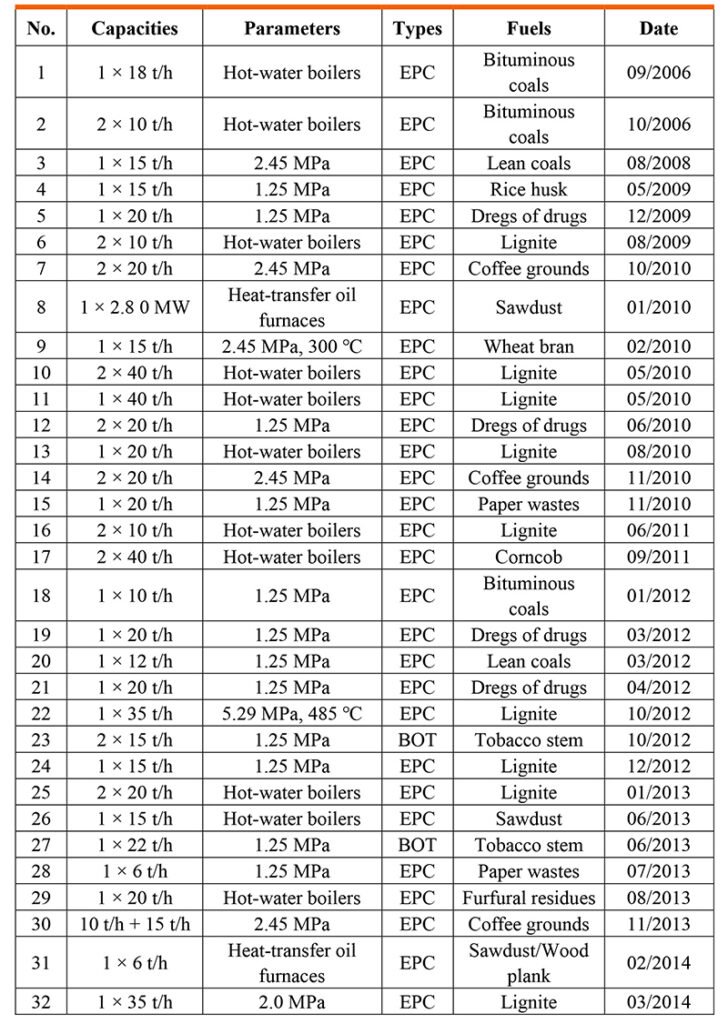

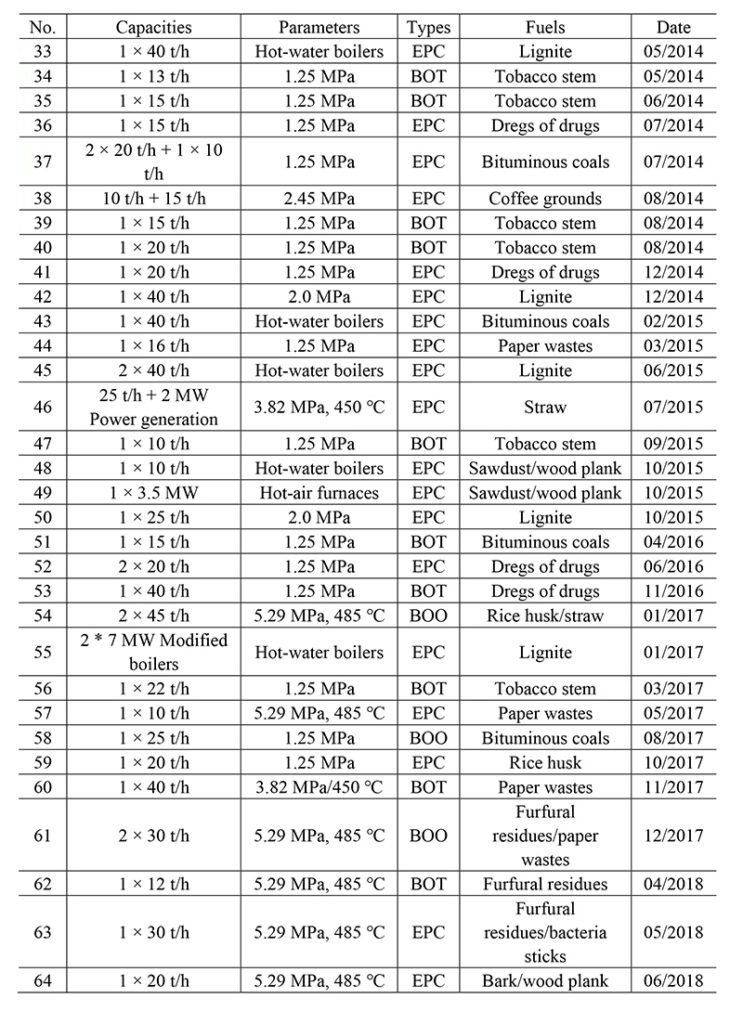

Cases

Photos of cases – coals

Pictures:

- A multi-fuel & multi-process circulating fluidized bed boiler in Dongying, Shandong Province, P. R. China; capacity: 35 t/h; fuel: lignite; constructed inOctober 2012;

- A multi-fuel & multi-process circulating fluidized bed boiler in Taiwan Province, P. R. China; capacity: 35 t/h; fuel: lignite; constructed in March 2014;

- A multi-fuel & multi-process circulating fluidized bed boiler in Taiwan Province, P. R. China; capacity: 25 t/h; fuel: lignite; constructed in October 2015;

- A multi-fuel & multi-process circulating fluidized bed boiler in Dongying, Shandong Province, P. R. China; capacity: 25 t/h; fuel: bituminous coals; constructed in August 2017;