The caliber of the installation process for the boiler heating surface significantly influences the operational safety of the boiler and the consistent provision of heat energy. Any inadequacies in the installation of the heating surface components can precipitate safety and operational mishaps during the boiler’s functioning, resulting in financial setbacks and disruptions in the enterprise’s heat energy supply. Hence, it becomes imperative for the installer to proficiently execute rigorous quality control measures during the installation process, thereby guaranteeing the secure and seamless operation of the boiler equipment.

Effectively do a good job in preparation for the installation

Effective Pre-Installation Preparations:

A robust preparatory phase is essential for ensuring a successful bulk boiler heating surface installation. Installation management personnel should proactively establish a comprehensive quality acceptance mechanism for heating surface installation. This mechanism should adhere to a systematic acceptance sequence. Generally, the supervisory unit is responsible for batch acceptance and sub-acceptance, while the construction unit oversees unit project acceptance. Moreover, designated professional quality inspection personnel should conduct informative quality testing throughout the acceptance process. This entails a meticulous approach wherein the installation team self-assesses the project, followed by quality management personnel conducting re-inspections. The project is then reported to the Ministry for subsequent quality re-inspection. Once these re-inspections are finalized, the superintendent and project owner collectively undertake the ultimate quality acceptance phase. This comprehensive quality acceptance process mandates thorough documentation of inspection findings, and the submission of a detailed quality inspection report for subsequent stages of assessment.

Thorough Preparations for Bulk Boiler Heating Surface Installation:

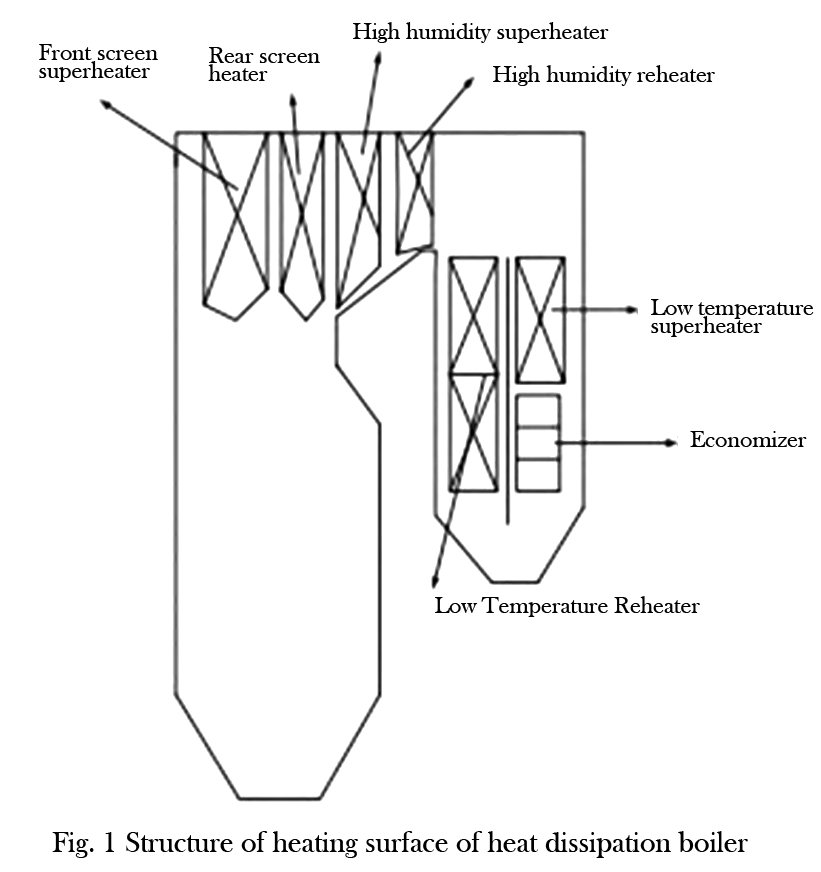

Prior to commencing the installation of heating surfaces for bulk boilers, meticulous and comprehensive preparatory measures are imperative. The installer’s initial focus should be on precisely aligning the positions of significant components such as large plate beams, columns, and load-bearing beams. Given that bulk boiler heating surface equipment is typically suspended on steel frames, meticulous positioning of these frames becomes crucial. Concurrently, the vapor system must be properly hung before proceeding with subsequent heating surface installation steps. Additionally, close attention must be paid to controlling potential errors in steel structure installation, ensuring that deviations remain within reasonable limits. The accurate installation position is contingent upon adherence to standardized height measurements of plate beams and center axes, with elevation lines and center axes serving as vital reference points. Ensuring the precision of drawn lines and equipment inventory figures is paramount. Given that water-cooled wall equipment often exceeds 4 tons in weight and requires timely lifting, rigorous testing is imperative to prevent mishaps like reverse lifting or erroneous lifting, which could significantly disrupt subsequent installation processes. Refer to Figure 1 for a comprehensive illustration of the bulk boiler’s heating surface structure.

Meticulous Inspection During Heating Surface Equipment Installation:

During the machinery installation phase of the heating surface equipment, thorough inspections are pivotal. External factors during transportation or production may impact equipment, resulting in surface defects such as deformation or other anomalies. Prior to installation, the installer should meticulously scrutinize both the external appearance and internal condition of tubes. This comprehensive assessment ensures the safeguarding of heating surface installation quality for bulk boilers.

Geometry Specification and Quality Control for Bulk Boiler Heating Surface Installation

2.1 Precision Alignment of Bulk Boiler Steel Frame Elevation

During the bulk boiler heating surface installation, operators must meticulously ascertain the precise elevation of the bulk boiler’s steel frame. Typically, a standard elevation of 1 meter is employed for bulk boiler installations. This standard elevation serves as a benchmark for determining installation locations and height measurements of other components within the boiler assembly process. To ensure optimal accuracy, the installer is tasked with clearly defining the elevation of the bulk boiler’s steel frame, thereby minimizing discrepancies between installation height and actual elevation. Following the elevation clarification, a vital step involves marking the elevation position by perforating holes and applying paint for clear demarcation. In cases where suspended structures are employed, the elevation of the bulk boiler’s steel frame at 1 meter is often referenced to establish the standard height of large plate beams or the top surface elevation of columns within the suspended structure. If discrepancies arise in the column specifications during their manufacturing, the installer can employ foundation mat thickness adjustments to rectify size variations. Notably, it is common for the installation of building materials to be incomplete on the top layer during the initial steel frame installation for bulk boiler heating surfaces. Waiting for the completion of these building materials could potentially impact the installation timeline for the bulk boiler. In light of this, a prudent approach is to utilize the standardized 1 meter height of the first layer of columns to clarify their installation height. Concurrently, meticulous control of column processing accuracy becomes paramount. In practice, a certain degree of processing error in columns is inevitable during the manufacturing process. These errors can accumulate and, over time, result in discrepancies between the actual elevation and the standard 1 meter elevation. Consequently, the installer must effectively counteract dimensional deviations in columns by making precise adjustments to the top structure of these components.

2.2 Precise Positioning of the Steam Drum

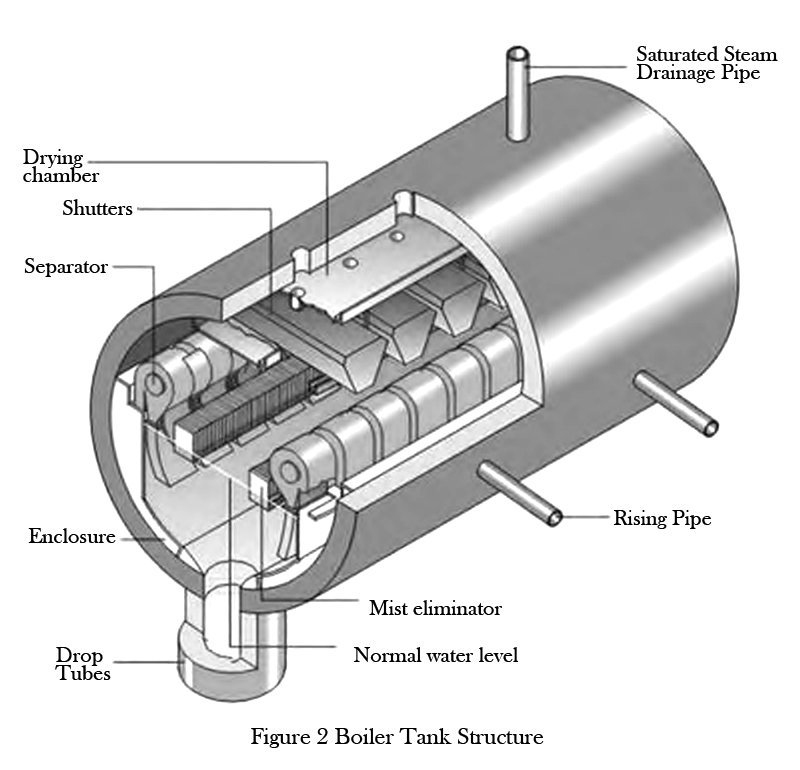

During the installation of bulk boiler heating surfaces, a critical task for the installer is to accurately determine the placement of the steam drum. Serving as the largest heating component in terms of weight and volume throughout the bulk boiler installation process, the steam drum assumes paramount importance. Achieving precise installation of the steam drum involves a comprehensive approach that encompasses both its installation location and standard elevation, while also considering horizontal positioning.

To ensure the meticulous control of steam drum installation quality, meticulous planning is a prerequisite before mounting the steam drum onto the bulk boiler. This entails establishing scientific and rational blueprints for steam drum equipment, including the delineation of both horizontal and vertical center axes. Notably, two crucial standards for precision must be upheld during installation:

- Vertical Installation Standard:

The discrepancy in installation standard height must remain within a tolerance of no more than 5 millimeters. This rigorous standard is indispensable to maintain the accuracy of the steam drum’s elevation. - Horizontal Installation Standard:

Horizontal positioning error should be meticulously controlled to approximately 2 millimeters. This exacting control ensures optimal alignment during the installation process.

Consequently, the installation process of the steam drum necessitates meticulous centering efforts. The deployment of equipment such as cranes and inverted chains can significantly assist installers in achieving this precise centering. Measurements between the vertical and horizontal center axes of the steam drum and columns can be undertaken using a steel tape measure, while standard height and horizontal spacing measurements can be facilitated by employing glass tubes. By leveraging the collected measurements, installers can accurately determine the optimal placement of the steam drum, thereby optimizing the overall quality of the steam drum installation and fulfilling the stringent quality requisites mandated for bulk boiler heating surface installations. Refer to Figure 2 for an illustrative representation of the boiler packet structure.

2.3 Managing Heating Surface Expansion Gaps

Within the operation of bulk boiler heating surface equipment and piping, high-temperature, high-pressure steam serves as the internal medium. Often reaching temperatures of up to 570°C, steam can undergo an actual expansion of up to 300 mm. Thus, meticulous control of expansion gaps within bulk boiler heating surfaces is a pivotal facet of current quality control protocols during installation. A deficiency in the expansion functionality of bulk boiler equipment components can yield excessive pressure buildup within the boiler, leading to safety incidents. It is imperative for installers to allocate sufficient space to accommodate expansion displacement, ensuring unrestricted expansion within the bulk boiler.

To effectively monitor and regulate bulk boiler expansion during operation, installers are required to integrate expansion indicator equipment beneath key locations, including the water-cooled wall, superheater, water drop tube, and steam drum. This real-time monitoring facilitates prompt corrective action. The placement of the expansion indicator device at platform positions eases installation and observation.

Attention should be paid to the length of the slide pin during expansion indicator equipment installation; it should not be excessive. Following installation, the pipeline spring positioning pin must be immediately removed. As the bulk boiler pipes are constructed with thin building materials above the metal expansion node, lifting and inverted chain equipment cannot be directly applied to the pipe shell. Protective measures, such as using non-fluorinated wet asbestos and similar materials, are indispensable during welding and pipe installation to prevent spattering.

Non-metallic expansion joints, while suitable for inverted transportation during installation, must not be pried with a crowbar. Their lower strength and stiffness necessitate the retention of equipment installation fixtures during site installation. Incorporating new expansion bends in bulk boiler piping design facilitates the accommodation of the boiler’s expansion.

The effective management of bulk boiler heating surface expansion forms a foundational premise for quality boiler installation. Installers are tasked with briefly analyzing and optimizing heating surface expansion, ensuring scientific and rational design modifications. In terms of pipeline direction, meticulous attention should be paid to the pipeline’s actual direction and expansion orientation during field installation. Prior to initiation, the installer must acquaint themselves with the required steel frame and boiler equipment installation site specifics, cross-referencing them with the boiler piping design drawings. Adapting to any design alterations guarantees coordination between standard height installation and actual coordinates.

Additionally, pipeline slope must remain within a controllable range throughout installation. Tolerances for deviations are permitted but must be rigorously managed. When installing piping valves, emphasis should be placed on safety and convenience to establish a secure foundation for subsequent operational tasks.

Furthermore, during bulk boiler installation, precise calibration of the hydrophobic ramp is essential. Errors in slope reservations can significantly impair both installation and operational functionality. Inadequate slope reservation for soot blowing pipes could lead to complications during operation. Ideally, the reserved slope for bulk boiler pipelines should exceed or equal 0.2%, while simultaneously allowing for free thermal compensation without restricting pipeline expansion. Comprehensive analytical assessment of pipeline slope reservations is thus crucial, underpinning the overarching quality of bulk boiler installations.

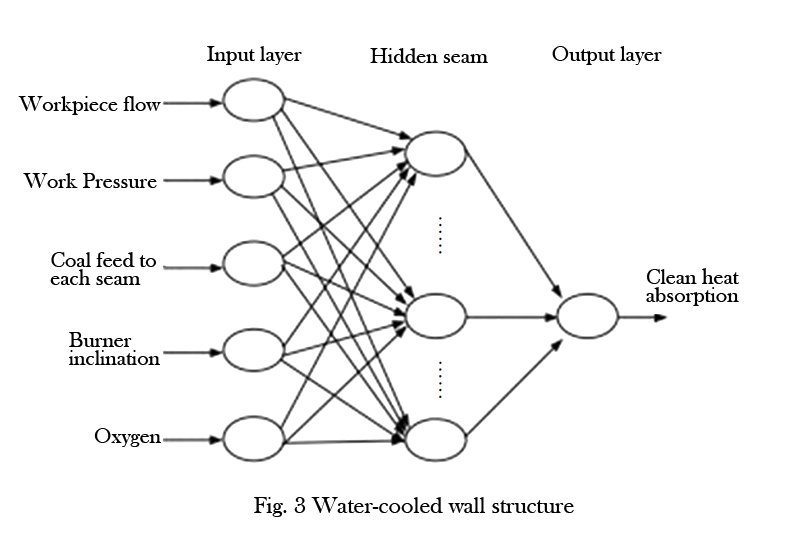

2.4 Enhancing Alignment Quality of Heating Surface and Water-Cooled Wall

The installation of bulk boiler package wall equipment and water-cooled wall equipment necessitates meticulous ground integration. During the combination of water-cooled wall and package wall equipment on the ground, installers undertake a comprehensive assessment of the equipment and component dimensions. In instances where discrepancies arise between actual sizes and design drawings, collaboration with design teams becomes imperative to rectify errors and prevent potential deformation issues during equipment lifting.

Upon hoisting the water-cooled wall and package wall equipment to their designated locations, meticulous adjustments are carried out using inverted chains to optimize center point alignment. Here, the installation elevation of the bulk boiler serves as the benchmark, and glass tubes are utilized for lateral detection to ascertain the precise installation height. This process ensures clarity and reinforcement of the standard height of the upper coupling box, the installation position, and the squareness.

Furthermore, meticulous optimization and adjustment of tube sheet verticality are undertaken. A geometric assessment of boiler steel frame beams and columns is performed, reinforcing qualified components to guarantee installation stability. The lower coupling box is subjected to adjustment and testing to holistically elevate the quality of bulk boiler installations.

Refer to Figure 3 for a detailed illustration of the water-cooled wall structure.

Ensuring Effective Pipeline Cleanliness Assurance

During the production and transportation of bulk boiler heating surface piping equipment, internal debris unavoidably accumulates. Failure to conduct thorough pre-installation cleaning can significantly compromise the subsequent safe operation of the bulk boiler. Consequences include piping valve blockages and the peril of pipe ruptures, particularly for critical-value bulk boilers where pipe diameters are less than 10 mm, heightening the vulnerability to blockages.

To uphold the quality and safety of bulk boiler installations, comprehensive internal pipeline cleaning is imperative. Installers can employ high-pressure air for blowing, with a recommended duration of 60 to 120 seconds. This procedure effectively dislodges internal dust and minor debris, preparing the pipeline for subsequent tests. Following blowing, a ball test can be conducted to eliminate residual debris, rust, and scale from the pipeline’s interior.

The balling test entails the use of steel balls initially, followed by wooden balls for the second round. Prior to releasing the ball, proper ventilation is crucial, ensuring that the receiving end of the pipe is ready for ball retrieval. Additionally, standardization is maintained by uniformly storing ball bodies, registering their volume, number, and diameter. A meticulous assessment of the pipeline’s condition post-ball test is necessary to confirm the absence of any overlooked balls. Once the ball test concludes, pipe ports are to be tightly sealed, with tape being applied to ensure secure closure. Furthermore, horizontal ports of overhead pipe rows and single pipes must be sealed to prevent the ingress of debris following the balloon test.

In conclusion, meticulous quality control in the installation of bulk boiler heating surfaces yields multifaceted benefits. Beyond enhancing the operational quality of the boiler and guaranteeing a steady supply of thermal energy, stringent control measures also serve to significantly reduce the likelihood of installation and production mishaps. Moreover, this approach contributes to the overall efficiency and advancement of an enterprise’s economic development. Consequently, during the installation process, it is imperative for personnel to diligently execute comprehensive quality control, thereby ensuring the impeccable installation quality of heating surface equipment.

[Source] Pan Jianyue, LOW CARBON WORLD 2023/6: 196-198

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.