As a global leader in the manufacture of HRSG boilers (waste heat boilers), DHB’s HRSG (waste heat boilers) are designed to meet the needs of industrial operations. Our engineers can create the right HRSG (waste heat boiler) for your application at a competitive price and delivery. DHB’s HRSG boilers (waste heat boiler) uses heat or combustible media in the working fluid to generate steam, exhaust gases, and waste liquids as heat sources to generate electricity. They are creating more value for businesses.

We have helped our customers significantly reduce their costs, and we have undertaken projects with complete turnkey start-up requirements for newly designed and built plants.

Applications for waste heat generation have expanded to the steel, cement, glass, non-ferrous metals, chemical, and petrochemical industries. With an essential role in the circular economy, energy saving, and emission reduction in various industries around the world, HRSG (waste heat boiler) not only saves you a lot of money but also is the right approach for environmental protection.

Heat Recovery Steam Generators (HRSG), as the name implies, refers to a boiler that uses various waste gases, waste materials, waste heat in waste gas or waste heat, and the heat generated by the combustion of combustible materials to heat water to a certain temperature. An oil-fired boiler, a gas-fired boiler, and a coal-fired boiler having a smoke box and a flue heat recovery are also referred to as Heat Recovery Steam Generators (HRSG), and the HRSG can produce hot water or steam through waste heat recovery to be supplied to other sections.

With the concepts of sustainable development, circular economy, energy conservation and emission reduction, and low carbon economy put forward one after another, China’s industry of heat recovery steam generation has developed from scratch.

Heat recovery steam generation refers to the technology of converting surplus heat energy generated during the production process into electric energy. Waste heat power generation is not only energy-saving but also conducive to environmental protection. The important equipment for Waste heat power generation is the HRSG. It uses heat or combustible media inside such working fluids as a waste gas and wastes liquid as heat sources to produce steam for power generation. As the working media temperature is not high, the boiler is large in volume and consumes a lot of metal. The waste heat used for power generation mainly includes the residual heat of high-temperature flue gas, chemical reaction, waste gas, waste liquid, low-temperature wastes, which are lower than 200℃, etc. At present, the application fields of waste heat power generation have also been expanded to steel, cement, glass, non-ferrous, chemical, and other industries.

HRSG unit:

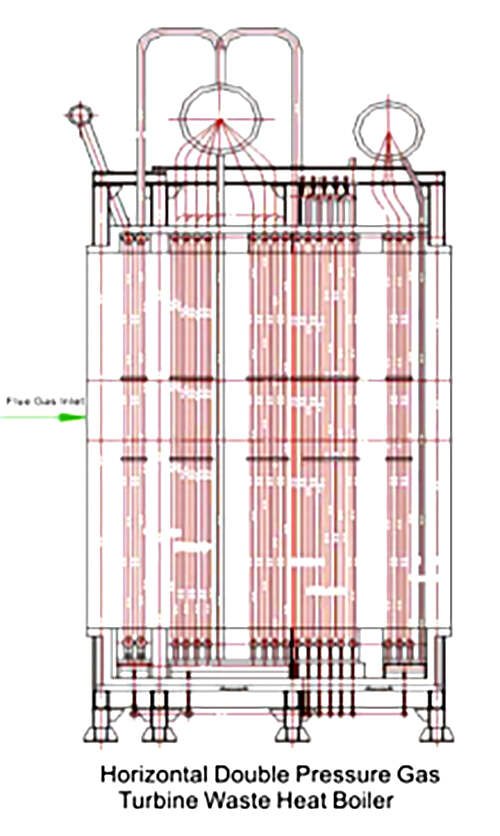

Specifications for the Gas Turbine Waste Heat Boiler

| Gas Turbine Exhaust Flow (NM³/H) |

318,000 | 387,000 | 400,000 | 465,000 |

| Boiler inlet flue gas temperature(℃) | 460 | 543 | 540 | 470 |

| Rated Evaporation Capacity(t/h) | 40 | 65 | 66(medium pressure section) | 60(medium pressure section) |

| 10(low pressure section) | 11(low pressure section) | |||

| Rated Steam Pressure(Mpa) | 2.75 | 3.82 | 3.82(medium pressure section) | 3.48(medium pressure section) |

| 0.4(low pressure section) | 0.88(low pressure section) | |||

| Rated Steam Temperature(℃) | 390 | 450 | 450(medium pressure section) | 435(medium pressure section) |

| 150(low pressure section) | 230(low pressure section) | |||

| Type of Boiler Structure | Horizontal arrangement, natural circulation | Horizontal arrangement, natural circulation | Horizontal arrangement, natural circulation | Horizontal arrangement, natural circulation |

I believe that the biomass furnace you designed for me will pay for itself within two years.

We will work with you to tackle your problems and reverse engineer the perfect solution for your application and needs. We want you to be worry-free, so you can reinvest your time and capital into your company and your communities so we can all impact global sustainability.

Manufacturer with 24 years of experience. We supply Alstom, Babcock & Wilcox, Covanta Energy, Amec Foster Wheeler, etc. DHB watches the product production process with you and gives you the rock-bottom price.