DHB Boiler is a manufacturer for A-class boiler (biomass boiler, power plant boiler, industrial boiler, HRSG, waste-to-energy boiler etc.) and correlated pressure parts. We supply boiler design, fabrication, installation, repair and maintenance.

We have helped our customers significantly reduce costs, and we have implemented projects with complete turnkey start-up requirements for newly designed and built plants.

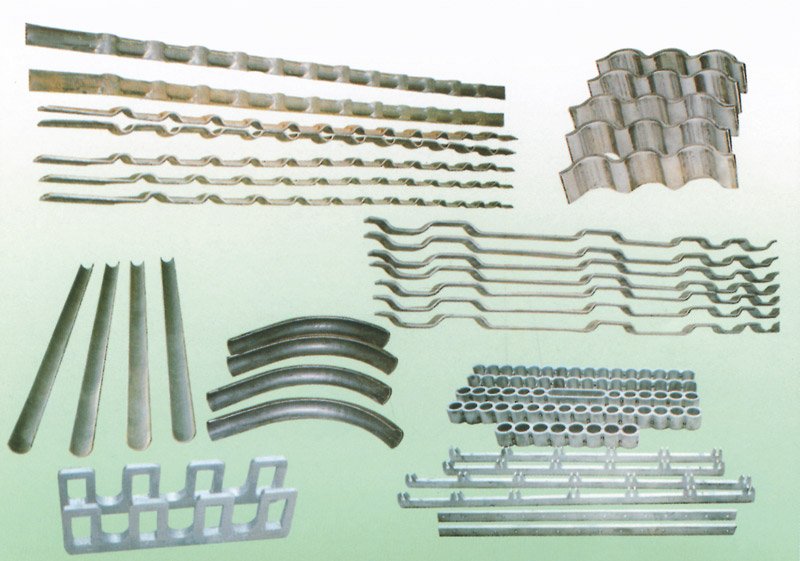

The tube shield is a common component of the heating part of tubes.

It is usually used in power station boilers. The useful life of tube shield is 3-5years.

Oil Gas Steam Boiler, Energy Saving Steam Boiler, Industrial Steam Boiler, Automatic Fire Steam Boiler Energy Saving Fully Automatic Fire Tube Industrial Oil Gas Steam Boiler for Heating fabrication

The tube shield has a variety of material and the selection of the material shall be subject to the original design of the boiler.

The tube shield is divided into straight pipe and bend pipe.

The main effect of tube shield is to protect the pipe and increase the service life of the pipe.

I believe that the biomass furnace you designed for me will pay for itself within two years.

DHB Boiler has over 20+ years of experience designing, deploying, and manufacturing CFB boilers and boiler equipment for CFB boilers and facilities of all kinds.

We will work with you to tackle your problems and reverse engineer the perfect solution for your application and needs. We want you to be worry-free so you can reinvest your time and capital into your company and your communities so we can all make an impact on global sustainability.

Manufacturer with 24 years of experience. We supply Alstom, Babcock & Wilcox, Covanta Energy, Amec Foster Wheeler, etc. DHB watches the product production process with you and gives you the rock-bottom price.