DHB is a leading manufacturer of air preheaters, DHB manufactures air preheaters designed to meet the needs of industrial operations. Our engineers can design the right air preheater for your application at a competitive price and delivery.

Air preheaters have a very common use in flue gas boiler systems because of their ease of use, simplicity of operation, safety of operation, and ability to improve the heat exchange performance of the boiler system.

We have helped our customers to significantly reduce costs and we have implemented projects with complete turnkey start-up requirements for newly designed and built plants.

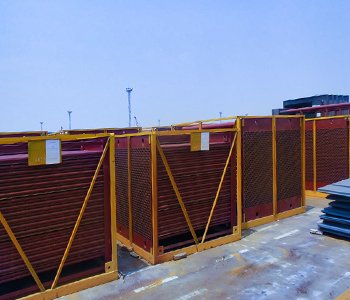

Air preheater(APH)is the shell and tube type heat exchangers used for preheating the air which is fed to the boiler or furnaces/ kilns for combustion of fuels. Air preheater’s primary objective is to extract the waste heat from the flue gases leaving the boiler. There are two types of air preheaters for use in steam generators in thermal power stations: One is a tubular type built into the boiler flue gas ducting, and the other is a regenerative air preheater.These may be arranged so the gas flows horizontally or vertically across the axis of rotation.

In the classical use, air preheaters are connected behind high-pressure steam boilers or thermal oil boilers with a flue gas temperature up to 400 ° C. Their exhaust temperatures lend themselves to preheat the combustion air up to 300 ° C,an air preheater save up to 10% of fuel costs and thus enables payback periods of less than two years. Meanwhile, air preheater also be used in low temperature ranges in order to make the most efficient use of the fuels and counter the rising fuel prices.

| Material | Carbon steel or equivalent |

| Structure | vertical |

| Tubes | enameled seam or seamless tubes |

| Tube OD | Customized |

| Enamel thickness | 0.34+/-0.06mm |

| Size | Customzied design |

| Brand | DHB |

| Remarks | Customized order is also accepted |

| Manufacturing process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment(Normalizing+ tempering) → Inspection→Cutting→Pipe piercing→welding→Sealing test→Painting→Packaging |

I believe that the biomass furnace you designed for me will pay for itself within two years.

DHB Boiler has over 20+ years of experience designing, deploying, and manufacturing CFB boilers and boiler equipment for CFB boilers and facilities of all kinds.

We will work with you to tackle your problems and reverse engineer the perfect solution for your application and needs. We want you to be worry-free so you can reinvest your time and capital into your company and your communities so we can all make an impact on global sustainability.

Manufacturer with 24 years of experience. We supply Alstom, Babcock & Wilcox, Covanta Energy, Amec Foster Wheeler, etc. DHB watches the product production process with you and gives you the rock-bottom price.