In the pursuit of the “double carbon” target, the imperative for comprehensive resource conservation has garnered unanimous support across various industries. Focusing primarily on energy conservation, especially in the realm of fossil fuels, has become a cornerstone of enterprise production strategies. Throughout the production processes of industrial enterprises, significant amounts of carbon dioxide and other pollutants are emitted alongside energy consumption, with waste heat emerging as a notable contributor. While waste heat presents itself as a valuable resource when harnessed, its uncontrolled emission contributes to heat pollution.

Enhancing the utilization of waste heat in industrial production emerges as a pivotal strategy to achieve both energy conservation and the reduction of pollutant emissions. Through a meticulous analysis of various methods employed in industrial waste heat utilization, this study delves into the realm of the iron and steel industry. It explores and proposes distinctive approaches for optimal waste heat boiler utilization, contributing to the broader objectives of energy and resource conservation, pollutant emission reduction, and the pivotal aim of achieving carbon peak and carbon neutrality. This research holds profound significance in steering industries towards a sustainable and environmentally responsible future.

Harnessing Industrial Efficiency: A Comprehensive Exploration of Waste Heat Boiler Utilization

Industrial Waste Heat Overview:

As of now, China’s industrial waste heat hovers around 7.2 billion GJ, predominantly concentrated in sectors such as iron and steel, electric power, building materials, and chemicals. Anticipating a decline in industrial energy consumption due to structural optimization and technological advancements, it is projected that by 2050, approximately 3.9 billion GJ of waste heat will persist. Despite this reduction, industrial waste heat utilization remains a priority, emphasizing the need for continued promotion in the coming decades.

Categories of Industrial Waste Heat Utilization:

The current landscape of industrial waste heat utilization primarily revolves around two categories: kinetic energy utilization and thermal energy utilization. Kinetic energy utilization involves converting thermal energy into electrical or mechanical energy through methods like thermal energy conversion, gas-steam combined cycle power generation (CCPP), and waste heat steam power generation. This category also encompasses joint utilization of thermal and potential energy, exemplified by technologies such as TRT, leveraging blast furnace gas to convert high-temperature, high-pressure impellers into kinetic energy for electricity generation.

On the other hand, thermal energy utilization is divided into two subcategories: incorporation within the production process for tasks like preheating and drying, and external use for heating purposes in daily life.

Optimizing Heat Utilization:

Considering the quality of waste heat, the industrial waste heat’s “heat utilization” focuses primarily on integrating it into the production process, followed by external output. This prioritization ensures that the waste heat is utilized effectively during production, enhancing operational stability. While external heat supply is subject to seasonality, utilizing high-grade waste heat in the production process remains a preferred choice. However, advancements in technology and a heightened sense of corporate responsibility have led to a fuller utilization of high-grade waste heat. Consequently, lower-grade waste heat, albeit more costly to utilize in production, becomes an optimal choice for heating applications.

Addressing Northern Heating Challenges:

Northern heating has witnessed continual growth in heat consumption, with urban floor areas in northern heating zones reaching 13.7 billion m2 by the end of 2019. Approximately 45% of the total heat demand is met by coal and gas boilers, resulting in nearly 1 billion tons of CO2 emissions annually. Projecting into the future, it is estimated that by 2050, the residential floor area in heating areas in China will surpass 20 billion m2, with a total heat demand of about 3.7 billion GJ. Effectively harnessing the 3.9 billion GJ of industrial waste heat can significantly mitigate the direct consumption of fossil energy for heat supply.

Case Studies: Waste Heat in Iron and Steel Industry:

To illustrate the practical application of waste heat utilization, this paper briefly explores two methods within the iron and steel industry: the utilization of waste heat from the sintering process during production and the application of waste heat from the steelmaking process in domestic heating.

This comprehensive exploration emphasizes the critical role of waste heat boiler utilization in achieving sustainable energy practices, resource conservation, and carbon emission reduction.

Maximizing Efficiency: Transformative Solutions for Sinter Waste Heat Utilization

2.1 The Crucial Role of Sintering Process in Iron and Steel Enterprises:

In the intricate process flow of iron and steel enterprises, the sintering process consumes approximately 15% of the total energy and generates a substantial 20% of the waste heat within the industry.

2.1.1 Insight into the Sintering Machine:

Taking a 110m2 sintering machine as an illustrative example, operating at a design rate of 95% with a utilization factor of 1.25t/(m2•h), it yields 1.1 million tons of sintered ore annually, fulfilling 78% of the blast furnace’s sintered clinker demand. Equipped with a 140m2 blower ring cooler featuring 4 groups of 20 air boxes, each supplied by a blower with an air volume of 20,100m3/h and air pressure of 4000Pa, the sintering workshop operates continuously for 365 days, with the sintering machine in operation for 330 days per year, running 4 shifts per day, 6 hours per shift, achieving a daily operation rate of 90%.

2.1.2 Unleashing the Potential of Waste Heat:

During the sintering process, forced cooling of the sintered ore produces exhaust gas, carrying away approximately 30% of the heat consumption of sintering. This waste heat, if recovered, holds the potential for substantial energy savings. In the pre-renovation state, the high-temperature flue gas in Section I of the ring cooler (310~370℃) was utilized for hot air sintering and preheating gas. Simultaneously, the relatively lower temperature flue gas in Section II (210~250℃) was released directly, resulting in energy wastage.

2.2 Innovating Residual Heat Recovery and Utilization:

2.2.1 Reform Strategies:

To optimize waste heat utilization, it is imperative to minimize flue gas leakage by enhancing the sealing of air boxes and flues. Section I flue gas waste heat is harnessed through the high-temperature heat exchanger of the waste heat boiler, while Section II flue gas waste heat is recovered using the low-temperature heat exchanger of the waste heat boiler. Additionally, the reform aims to enhance flue gas purity and reduce equipment damage through effective dedusting methods.

2.2.2 Comprehensive Reform Initiatives:

A holistic overhaul is undertaken, addressing the upper sealing cover, lower air inlet box, air inlet pipe, and flue of the ring cooler. The addition of heat insulation materials minimizes flue gas leakage and associated heat loss. The introduction of a new gravity dust collector facilitates the redirection of high-temperature flue gas from Section I to the high-temperature heat exchanger of the waste heat boiler post-dedusting. Simultaneously, the low-temperature flue gas from Section II is channeled to the low-temperature heat exchanger of the waste heat boiler, ensuring the temperature of the exhaust gas after heat exchange remains below 120℃.

Advancing Sustainability: Innovative Approaches to Sinter Waste Heat Transformation

2.3 Pioneering Waste Heat Transformation Technology Program:

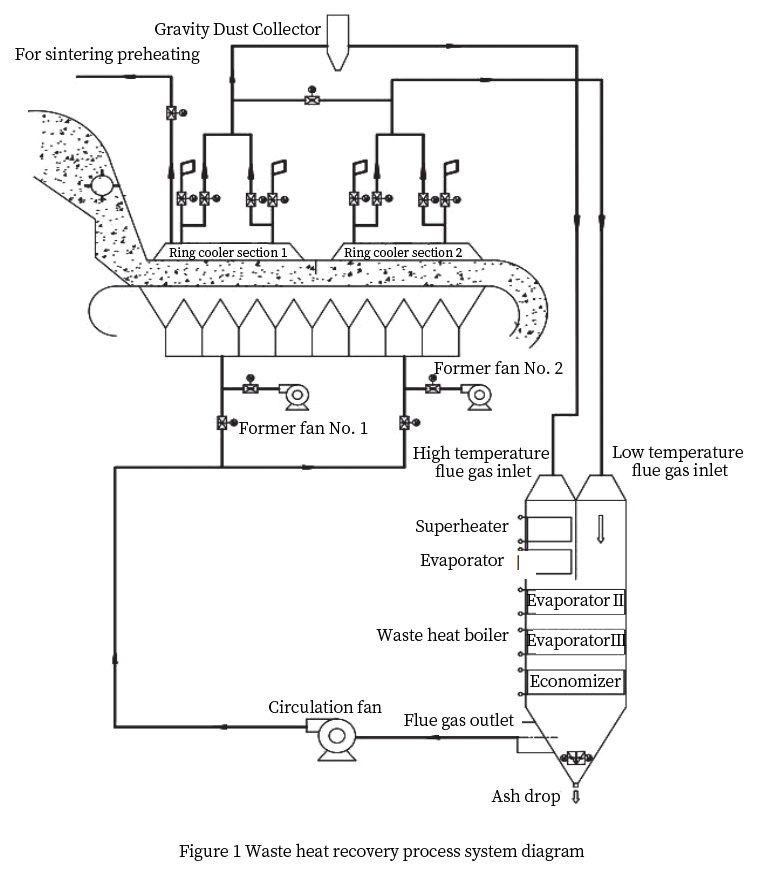

The waste heat utilization project embraces a closed air volume full cycle process. This process orchestrates a closed loop, wherein flue gas undergoes a cycle of “ring cooling heat absorption – waste heat boiler exothermic – ring cooling machine air box – ring cooling and then absorbing heat.” This closed-loop system eliminates the need for external flue gas discharge, reducing the demand for environmental protection facilities and lowering energy consumption. The circulation system requires only a minimal infusion of air to counter flue gas leakage, leading to further reductions in energy consumption for motors, fans, and auxiliary equipment. A heightened dust removal component serves to diminish wear on the circulating pipeline, circulating fan blade, and waste heat boiler heat exchangers, contributing to sustained normal working conditions for each facility in the sintering process. The waste heat recovery process system is depicted in Figure 1.

Waste Heat Recovery Process System

2.3.1 Composition of Waste Heat Recovery System:

The sintering waste heat recovery system comprises two primary subsystems: the waste heat collection and heat exchange system and the flue gas recycling system. The waste gas enters the waste heat boiler from the ring cooler through designated channels, engaging in heat exchange within the waste heat boiler’s heat exchanger. Simultaneously, the flue gas can enter the ring cooler from the waste heat boiler through channels such as the flue gas pipeline, air duct, and airbox to cool the sintered ore, forming a seamless connection between the two subsystems and achieving zero flue gas emission.

2.3.1.1 Waste Heat Collection and Heat Exchange System:

To optimize the waste heat of different temperatures in sections I and II, modifications include the isolation and switching functionality of the two sections. This encompasses sealing hood isolation, flue gas pipe connection and switching, and optimization of supporting pipelines. These modifications facilitate flexible adjustment of air inlet volume and temperature for each section of the waste heat boiler, enhancing its operational efficiency.

2.3.1.2 Flue Gas Recycling System:

The flue gas recycling system and the original air blower system at the sintering ring cooler alternate roles based on the operational status of the waste heat boiler. The modification involves the installation of a recycling fan, a tee pipe in the air duct, and butterfly valves, enabling seamless switching between the blower and recycling flue gas.

2.3.2 Main Equipment:

Key equipment in the waste heat recycling system includes a low-temperature waste heat boiler, feed water pump, deaerator, expanding vessel, and circulating fan. Main parameters are detailed in Tables 1 and 2.

Table 1 Parameters of waste heat boiler

| Project | Unit | Working condition value |

| Boiler inlet high temperature flue gas flow | 104Nm/h | 13 |

| Boiler inlet high temperature flue gas calculation temperature | ℃ | 350 |

| Boiler inlet low temperature flue gas flow | 104Nm/h | 9 |

| Calculated low temperature flue gas temperature at boiler inlet | ℃ | 250 |

| Steam pressure | MPa | 1.270.1 |

| Rated evaporation | t/h | 14.5 |

| Steam temperature | ℃ | 2505 |

| Water supply temperature | ℃ | 20 |

Table 2 Parameters of circulating fan

| Index Name | Air Volume | Wind Pressure | Rated Power | Protection class | Rated Voltage | Insulation grade | Efficiency |

| Technical Parameters | 380000m/h | 5600Pa | 800kW | IP54 | 10kV | Grade F | 97% |

2.4 Benefit Analysis of Sinter Waste Heat Recovery and Utilization:

2.4.1 Economic Benefits:

The recovery of waste heat from high-temperature flue gases in sections I and II of the ring cooler promises substantial economic advantages. The anticipated annual steam production of 105,000t/a translates to a noteworthy energy-saving benefit amounting to RMB 18.9 million. Moreover, upon the successful implementation of the sintering waste heat recovery system, annual savings are projected at RMB 8.2 million in electricity costs, RMB 2.54 million in operation soft water costs, RMB 10,000 in compressed air costs, and RMB 20,000 in circulating cooling water costs. The cumulative economic benefits post-project implementation are estimated to reach RMB 10.77 million annually.

2.4.2 Social Benefits:

Following the operational commencement of the sinter waste heat recovery system, the annual steam production is forecasted to reach 105,000t/a. With the production efficiency of a 35t/h coal-fired boiler considered, the waste heat utilization project is poised to reduce coal consumption by 15,750t, equivalent to 11,250t of standard coal. This reduction in coal consumption has far-reaching environmental benefits, leading to significant decreases in greenhouse gas emissions and other pollutants. An analysis of the standard coal composition indicates a reduction of 2.841tCO2 emissions per ton of coal burnt. The operational integration of the project is expected to effectively curtail the emission of greenhouse gases and other pollutants, as highlighted in Table 3.

Table 3 Coal saving and pollutant emission reduction of the project

| Coal savings (million tce/a) | Pollutant reduction(t/a) | ||||

| SO2 | NOx | CO | CO2 | Ash residue | |

| 1.12 | 180 | 141.23 | 682.09 | 25591.87 | 2250 |

The significant reductions in coal consumption and pollutant emissions underscore the project’s positive contributions to environmental sustainability, aligning with global efforts to mitigate climate change and promote cleaner industrial practices.

3 Utilization of Steelmaking Waste Heat for Heat Supply:

3.1 Challenges and Solution Ideas:

The primary challenge in utilizing industrial waste heat for heating lies in managing the disparity between the fluctuating waste heat generated in production and the relatively stable heating area demand. This imbalance can lead to underutilization of waste heat and instability in meeting heating demands. A systemic approach is proposed, leveraging system thinking to integrate waste heat from the entire factory or industrial park for centralized heating, enhancing system regulating capabilities and maintaining balance.

3.2 Waste Heat Heating Situation Before Integration:

Taking the waste heat heating of an electric furnace in a steel plant as an example, inefficiencies were observed in the utilization of waste heat. For instance, in Zone A, where a waste heat heating system was established, there was surplus heating capacity that was not fully utilized. Additionally, Zone B and Zone C faced challenges in coordinating waste heat utilization due to their independent operations, leading to energy waste.

3.3 Scheme Design for Integrated Utilization:

The integration scheme aims to capitalize on surplus heating capacity by connecting Zone A’s circulating water to Zones B and C, achieving interconnection. This design ensures optimal utilization of waste heat, reducing energy waste and expanding the overall heating area. Furthermore, the interconnected circulating water systems enhance flexibility and resilience in case of emergencies.

3.4 Heat Supply Calculation Post-Integration:

The calculation of heat supply is represented by Equation (1). Subsequent to the computation, the heat balance for waste heat heating in Zone A is detailed in Table 4, while the heat balance for Zones B and C is presented in Table 5.

Equation (1):

Q=c⋅qm⋅Δt

Where:

- c represents the specific heat capacity of water (4200 J/(kg.℃)),

- qm denotes the mass flow rate (kg/s),

- Δt signifies the supply and return water temperature difference (℃).

Table 4 Heat balance of waste heat heating in zone A

| Total heating area(m2) | Heating standard (W/m2) | Required load (kW) | ||

| 132000 | 50 | 6600 | ||

| After expansion | Flow rate(t/h) | Supply water temperature (℃) | Return water temperature (℃) | Existing load (kW) |

| Primary side parameters | 1330 | 75 | 69 | 8379 |

Note that the flow rate, water supply temperature and return temperature in the table are all primary side parameters.

Table 5 Heat balance for waste heat heating in Zone B and C

| Total heating area(m2) | Heating standard (W/m2) | Required load (kW) | ||

| 132000 | 50 | 6600 | ||

| After expansion | Flow rate(t/h) | Supply water temperature (℃) | Return water temperature (℃) | Existing load (kW) |

| Primary side parameters | 1800 | 60 | 56 | 7560 |

Note that the flow rate, water supply temperature and return temperature in the table are all primary side parameters

3.5 Calculation of Steam Saving After Integration:

The integration’s impact on steam saving was analyzed, considering the thermal efficiency of the heat exchanger. The integration project demonstrates the potential to save significant steam, contributing to overall energy conservation.

3.6 Analysis of Integration Benefits:

Economically, the integration project increases the heating area, saving steam and yielding an estimated annual energy-saving benefit of around RMB 8 million. Socially, substantial reductions in steam consumption and coal usage translate to environmental benefits, with significant decreases in greenhouse gas emissions and other pollutants.

Table 6 Standard Coal Savings and Pollutant Emission Reductions of the Project

| Coal savings (million tce/a) | Pollutant reduction(t/a) | ||||

| SO2 | NOx | CO | CO2 | Ash residue | |

| 0.44 | 72.1 | 56.6 | 273.2 | 10250.3 | 802 |

The integrated approach not only yields economic benefits but also significantly contributes to environmental sustainability, aligning with the principles of efficient resource utilization and reduced environmental impact.

Conclusion: Unlocking the Potential of Waste Heat Utilization

This comprehensive exploration of industrial waste heat utilization, including its connection to northern heating and applications in the sintering and steelmaking processes, underscores the critical need for innovative approaches. The paper concludes with key insights:

- Sintering Process Waste Heat Utilization: To optimize the utilization of waste heat in the sintering process, it is imperative to introduce high-temperature flue gas from the I section of the ring cooler into the waste heat boiler, complemented by a gravity dust collector. This strategic configuration ensures the complete circulation of flue gas throughout the I and II sections of the ring cooler, eliminating centralized flue gas emissions.

- Steelmaking Process Waste Heat Utilization: Effectively harnessing waste heat in the steelmaking process demands a systemic approach. By integrating waste heat resources across the entire plant, a stable supply and demand equilibrium can be achieved while maximizing the utilization of waste heat. This approach ensures that waste heat is utilized to its fullest potential.

- Holistic Resource Integration: Emphasizing the importance of system thinking, the paper highlights the significance of integrating waste heat resources plant-wide. This holistic approach is vital to achieving a stable supply and demand balance while maximizing the utilization of waste heat.

- Diverse Avenues for Waste Heat Utilization: The study recognizes that waste heat utilization presents numerous avenues. With the guiding principle of comprehensive resource conservation, the field of waste heat utilization is poised for continual growth and development. The adoption of comprehensive resource conservation strategies will further enhance the adequacy of waste heat utilization.

In conclusion, waste heat utilization is a dynamic and evolving field that merits sustained attention. As industries continue to align with comprehensive resource conservation strategies, the potential for waste heat utilization to contribute to energy efficiency and environmental sustainability will only expand, making it a focal point for ongoing exploration and innovation.

DHB Boiler

Discover The Superior Quality And Cutting-Edge Technology Of DHB Boilers. Explore Our Range Of Biomass Boilers, Waste Heat Boilers, And More. Take Your Industrial Operations To New Heights With DHB Boiler.