boiler economizer Manufacturer

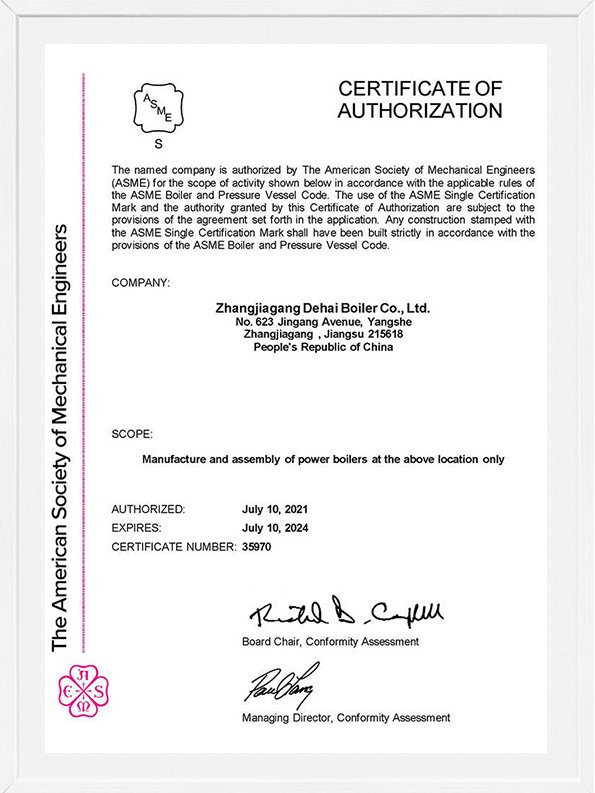

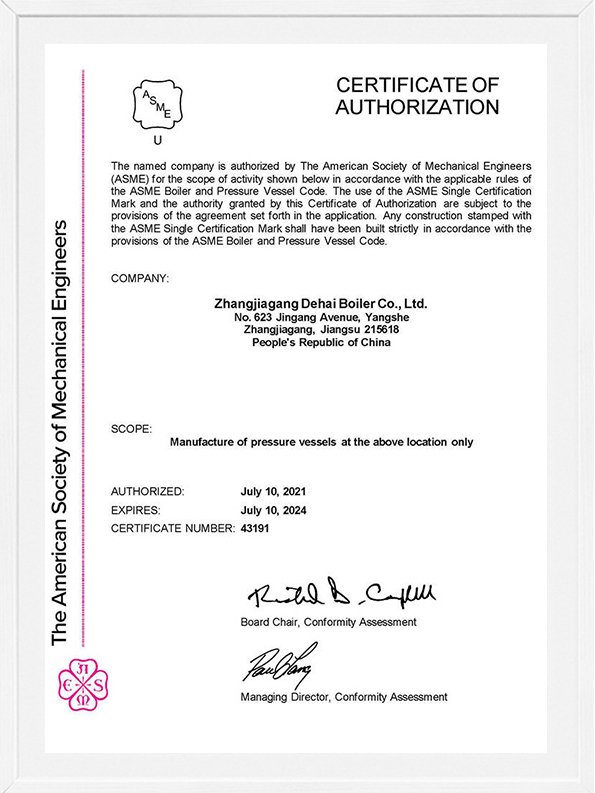

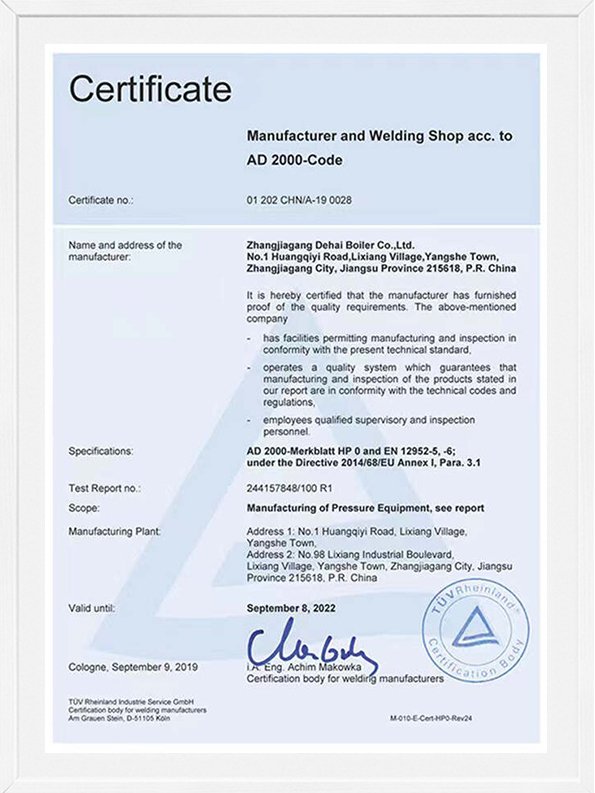

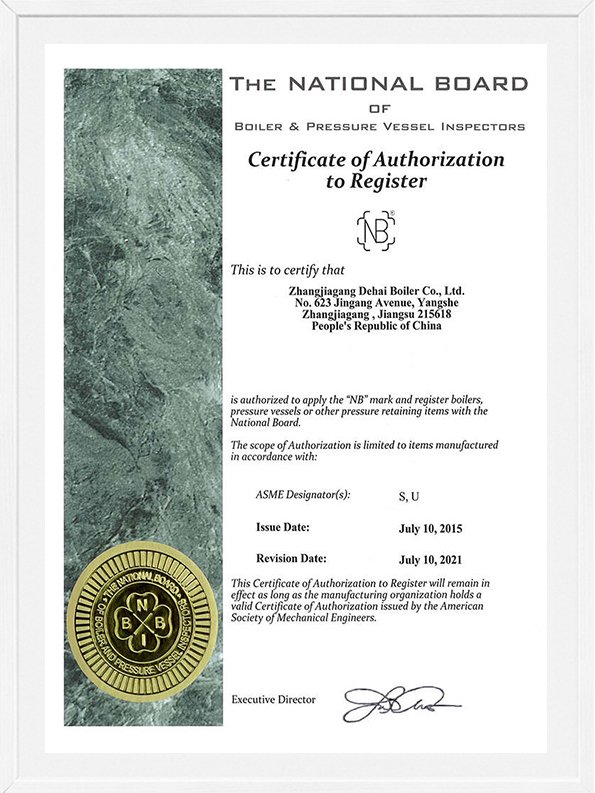

ASME/TUV/ISO certification to ensure the quality of boiler economizer.

Fuel saving and operation cost reduction

The exhaust temperature of the boiler is usually betwee 200°C and 250°C. Therefore, the installation of boiler economizer for heat recovery can effectively improve the efficiency of the boiler and extend its service life

Competitive price

We are a manufacturer. Our factory and steel raw material factory are in the same city, which means we can save cost and time in transportation. You will get high-quality products at the best price.

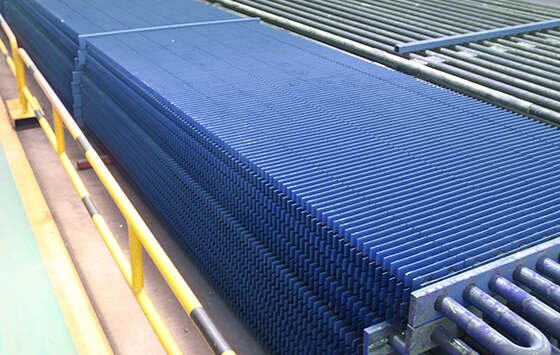

Excellent Quality Industrial boiler economizer

We can manufacture three types of boiler economizer, bare tube economizer, H-finned tube economizer and spiral finned tube economizer.

Spiral Finned Tube Economizer

The spiral finned tube economizer is a newly designed heat transfer equipment, consists of spiral fin tubes to overcome the serious

H-Finned Tube Economizer

H-finned tube economizer is high efficient heat exchanger economizer which is consisted of H-finned tubes. H-finned tube economizer can enlarge the heat exchange area and reduce the number of tubes. It also can increase the flue gas flow area in order to reduce the flue gas flow speed and abrasion.H-finned tube can be made as double H finned tubes , with high rigidness to fit long tube row.

Bare Tube Economizer

The bare tube economizer is a kind of economizer which is made from seamless steel tube.

Meet national boiler manufacturing standards

e.g. Russian GOST, American ASME, European EN12952, Indian IBR

Can meet customer delivery status

Minimize the labor required for welding after the goods arrive at the site

Fast delivery

Short procurement cycle of raw materials, supporting manufacturers are in the vicinity of Jiangsu, Zhejiang and Shanghai

better price

Price advantage, we are a manufacturing factory, not a trading company

Industry veteran of Boiler Economizer

DHB Boiler is one of the best boiler manufacturing suppliers in China. Including Utility Boiler, HRSGBoiler, coal-fired, oilgas) -fired, coal-water-slurry-fired and garbage-fired steam/hot water boilers, organic heat carrier boilers, etc., and Boiler spare parts (Economizer, Finned tube, Header, Steam drum, Superheater, Water wall panel, Air preheater, Cyclone separator, etc.,)We ensure the delivery time, high quality, and the best after-sale service for you.

24

20+ Years Of Experience In Industry R & D And Manufacturing

6

6 Certification To Ensure That Products Meet Local Standards

36

Delivered To 36 Countries And Regions

Estimated price for ordering boiler economizer

We have very competitive prices because of the advantages of geographical location and supply chain. As a boiler manufacturer, we can better control the cost and quality.

Design fee

We usually design according to the drawings you provide. If you have design needs, the design fees we charge will be very reasonable.

Sample Product fee

We can provide free material samples for you to test whether they meet your standards.

30% T/T Fee

30% TT deposit in advance

30% Material Payment

We will charge 30% for materials

40% Final Fee

Complete your payment within a certain period and receive the products you ordered for.

Logistic and packaging

Before shipment, we will strictly check the products again and send them to you to ensure that you receive high-quality products.

1

Qulity testing

Each product is manufactured and strictly inspected before shipment

2

Package

We will strictly pack the goods to ensure that they are not damaged during transit

3

Transport

We will transport the goods at the fastest speed and shorten your waiting time

- For 90% of shipment, We will go by sea, to all main continets such as South Amercial, Middle Esat, Africa, Oceania and Europe etc. Either by container or RORO/Bulk shipment.

- For neighhorhood contries of China, such as Russia, Mongolia, Kazzkhstan, Uzbekistan etc., we can ship by road or railway.

36+ countries and regions use our products

You can see if there are similar engineering needs with you, and tell us so that we can better serve you.

Contact Us, please.

| Project Name | Product(s) Name |

|---|---|

| AMEC Foster Wheeler/FATIMA Economizer project | H type finned tube economizer module |

| USA Foster Wheeler/CLECO Project | Economizer Module of 330MW CFB Boiler |

| USA Covanta Energy/Alexandria Power Plant | Waste-to-energy boiler economizer, superheater |

| Australia RCR Energy/QAL Project | Convection bank tube, economizer U bends platen |

| Finland Foster Wheeler/MEJILLONES project | Economizer of 300MW CFB Boiler |

| Indonesia Wuhan Kempinsh | Economizer, bends, water panel |

| Zhejiang Jiaxing Power Plant | 2*1000MW Ultra-supercritical unit of 1#, 2# boiler of economizer |

frequently asked questions

How do you control the quality?

1) All DHB machines are in strict accordance with the ISO quality and CE system requirements.

2) Each procedure is crafted by professional Skilled labour, followed by particular QC

3) All information of our products can be checked in efficient management system.

Main manufacturing equipment?

Our products' quality is ensured by advanced, excellent facilities and manufacturing equip-ment. We have introduced 500 sets of advanced processing and inspection equipment,including plasma cutting machine,NC drilling equipment, automatic submerged arc weldingsystem, welding equipment and real-time online imaging detection system, etc.,which suc-cessfully ensure excellent quality of our products.

How long is your delivery time?

It is very dependent on the capacity of equipment. Delivery time should be determined after technical discussion. Please contact our sales.

What about after-sale service?

Our boilers have one year warranty period or depending on your requirements.

ls there any item belong to hazardous nature.

There is no hazardous nature in the item.

Do I have a choice of colors?

DHB Boilers are available in many different color combinations.

Contact DHB Boiler to Start Your Business

This is a new opportunity for you to make a lot of money. Seize it and let the biomass boiler start making money for you. You can recover the cost and start making money in 1 years at the earliest. Contact us immediately

© 2023 DHB Boiler LLC. All rights reserved.