Biomass Boiler Manufacturer

Save Labor Costs And Enable The Fastest Possible Assembly.

Fast production time

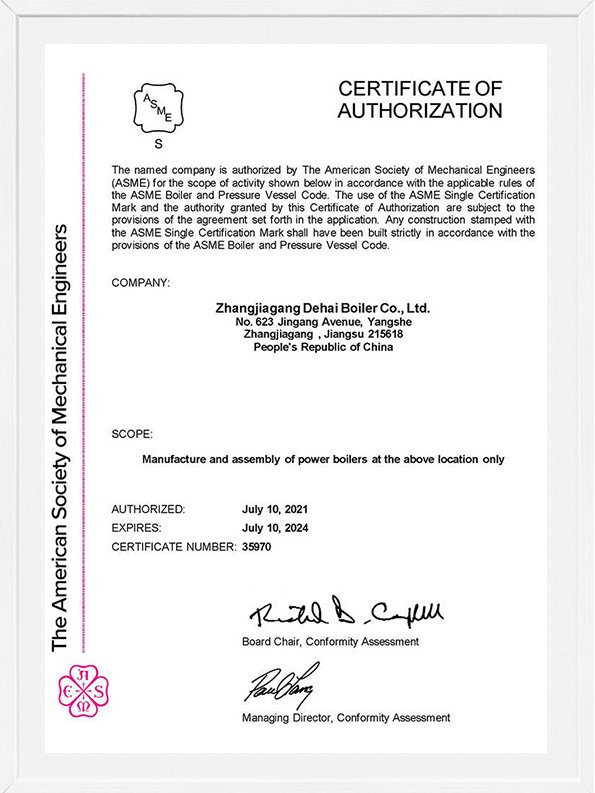

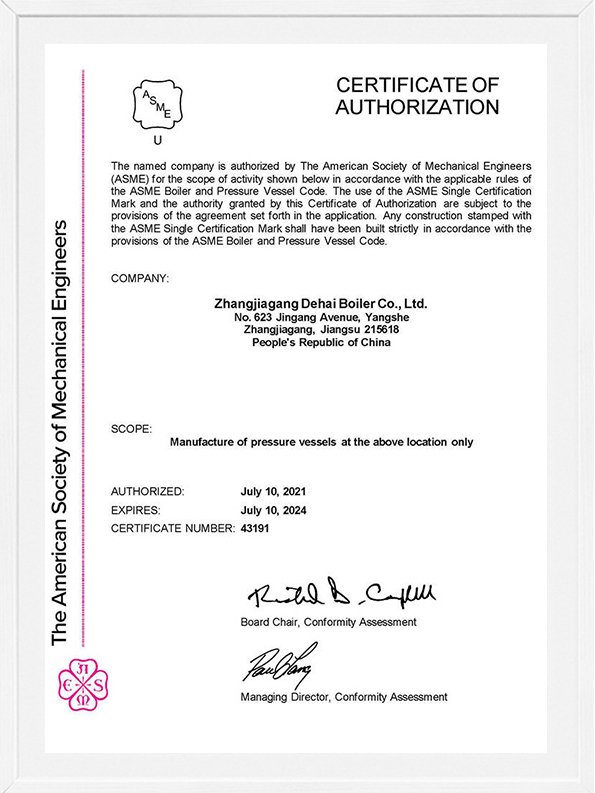

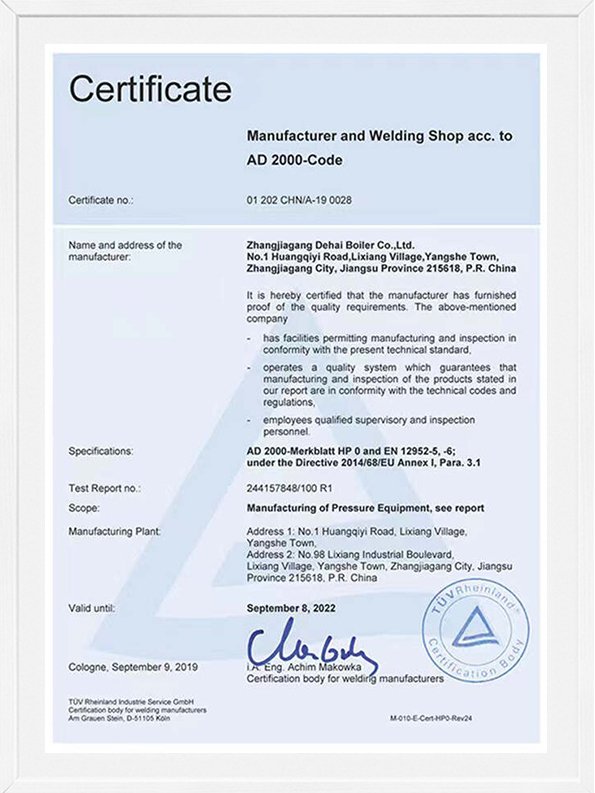

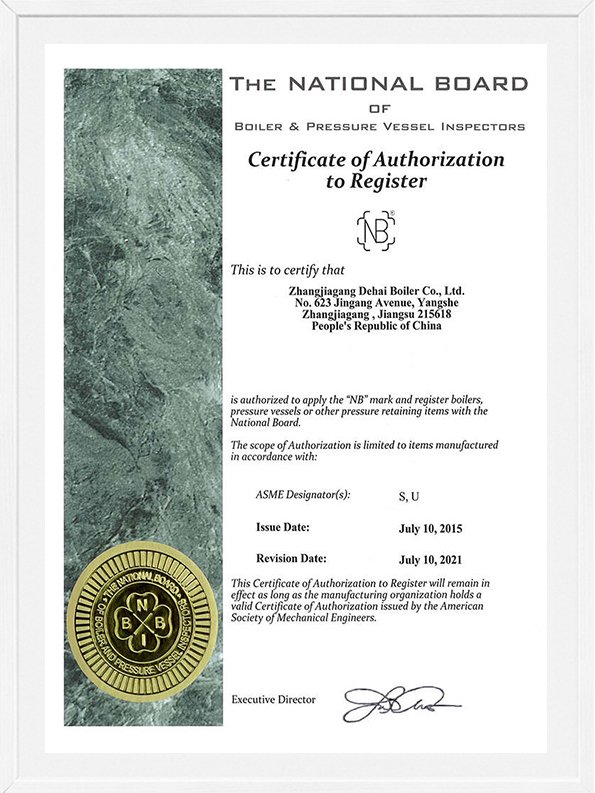

Time is money. We have A-Class Boiler Manufacture License, ASME/TUV/ISO 3834 Certified etc. We are familiar with the standards of various countries. We can produce your products as quickly as possible and create value for you as soon as possible.

Competitive price

We are a manufacturer. Our factory and steel raw material factory are in the same city, which means we can save cost and time in transportation. You will get high-quality products at the best price.

Biomass boiler, turning waste into power generation energy

Let sawdust, bagasse, palm husk, rice husk and straw become energy for power generation, and create more electricity for your enterprise to create higher value.

Exquisite production technology

ISO 3834 certificate, Appropriate welding equipment to ensure product quality and improve efficiency

Full combustion

Reasonable heat surface and burning device, heat efficiency is 4%~5% higher than national standard.

Safe and Reliable

Reasonable flue gas speed, heating surface without ash deposition and no abrasion, under the condition of no soot-blowing, the boiler can work full-load, high-efficiency and safety in long term.

Large capacity

The big and tall boiler furnace can be designed according to the different fuel to improve the burning rate of fuel and remove black smoke.

High production capacity

Advanced CNC equipment is the guarantee of quality

Eco-friendly and energy

all kinds of fuel, such as wood chips, bagasse, Palm husk, rice husk, straw

Industry veteran of high-power biomass boiler

DHB Boiler is a manufacturer for A-class boilers(biomass boilers, power plant boilers, industrial boilers, HRSG, waste-to-energy boiler etc.) and correlated pressure parts. We supply boiler design, fabrication, installation, repair and maintenance.

24

20+ Years Of Experience In Industry R & D And Manufacturing

6

6 Certification To Ensure That Products Meet Local Standards

36

Delivered To 36 Countries And Regions

How do I choose the right biomass boiler

for my needs?

When selecting a biomass boiler, consider factors like heat output capacity, fuel type and availability, efficiency ratings, space requirements, and potential installation and maintenance costs. Consulting with a reputable supplier or installer can help you make an informed decision.

Main Technical Parameters

Capacity range of boiler: 6–160 t/h

Pressure range of boiler: low-temperature & low-pressure steam boilers, medium-temperature & medium-pressure steam boilers,high-temperature & high-pressure steam boilers and hot-water boilers

Thermal efficiencies: 88–92%

Suitable fuels: bituminous coals, anthracite,lignite, lean coals, coal gangue, oil shales, biomass fuels, agricultural wastes, coffee grounds, residues of traditional Chinese medicine,furfural residues

Range of calorific value: 1500–6000 kcal/kg

Furnace box temperature: 850–900 ℃ (depending on operation situations of coal combustion)

Inlet temperature of cyclone separator: ~500 ℃

Outlet temperature of flue gas for boiler: ≤ 145 ℃

Carbon-containing rate of bottom slag: < 1%

Structure of furnace: membraned walls

Heat-transfer medium: water or conduction oil

Initial nitrogen oxide emission: ≤ 200 mg/m3

Control method of NOx: low-temperature combustion + “coupling of SNCR & SCR”

Desulfurization method: addition of limestone to the furnace + fine desulfurization in the tail stage

Dusting method: high-performance bag dust-cleaning + wet electrostatic dust-cleaning

Logistic and packaging

Before shipment, we will strictly check the products again and send them to you to ensure that you receive high-quality products.

1

Qulity testing

Each product is manufactured and strictly inspected before shipment

2

Package

We will strictly pack the goods to ensure that they are not damaged during transit

3

Transport

We will transport the goods at the fastest speed and shorten your waiting time

- For 90% of shipment, We will go by sea, to all main continets such as South Amercial, Middle Esat, Africa, Oceania and Europe etc. Either by container or RORO/Bulk shipment.

- For neighhorhood contries of China, such as Russia, Mongolia, Kazzkhstan, Uzbekistan etc., we can ship by road or railway.

36+ countries and regions use our products

You can see if there are similar engineering needs with you, and tell us so that we can better serve you.

These are some of our customers. If you need more cases, contact us, please.

| Project Name | Product(s) Name |

|---|---|

| Malaysia Felda Palm Industries Sdn.Bhd. | Biomass Boiler |

| Thailand THA CHANG Oil Palm Industries Co., LTD | Biomass Boiler |

| Hubei Sunshine Kaidi New Energy | Biomass Boiler |

| Hubei Wuhan Kaidi Power | 5*65t/h Biobass Boiler pressure parts |

| Yunnan Yunjinglin Paper Co., LTD | 1t/h Biomass Boiler |

This product is very nice, I will choose this supplier next time I need to buy accessories, very professional! !

frequently asked questions

To save you from worries, here are some facts you need to know about our biomass boiler:

How to get a boiler price?

Pls tell us below information to confirm the boiler model first, and then offer the right boiler price:

1.1 Which fuel you prefer for the boiler, coal, biomass, gas & oil, or others?

1.2 The boiler capacity

1.3 The boiler pressure

1.4 The boiler application

How long is the product warranty period ?

Our boilers have one year warranty period or depending on your requirements.

How long is your delivery time?

It is very dependent on the capacity of equipment. Delivery time should be determined after technical discussion. Please contact our sales.

What about after-sale service?

Our boilers have one year warranty period or depending on your requirements.

Contact DHB Boiler to Start Your Business

This is a new opportunity for you to make a lot of money. Seize it and let the biomass boiler start making money for you. You can recover the cost and start making money in 1 years at the earliest. Contact us immediately

© 2023 DHB Boiler LLC. All rights reserved.