Biomass Boiler Manufacturer

Save Labor Costs And Enable The Fastest Possible Assembly.

Our Team

Our product is the latest and the best, the requirements of governments of all countries are a piece of cake, our product can meet all your needs!

A pioneer of theory and application

- A person who pioneered the idea and system of elementary characterization of the thermochemical

reaction characteristics of waste. - A person who breaks through the centralized treatment technology of multiple organic wastes in the same

furnace. - A person who invented the miniaturization of circulating fluidized bed.

A Supervisor

6

50+

200+

70+

Prof. Yanguo Zhang

Chief scientist

Long-term professor of

Tsinghua University

Outstanding Paper Award Winner

Highly Cited Paper Scholar

What is TFB?

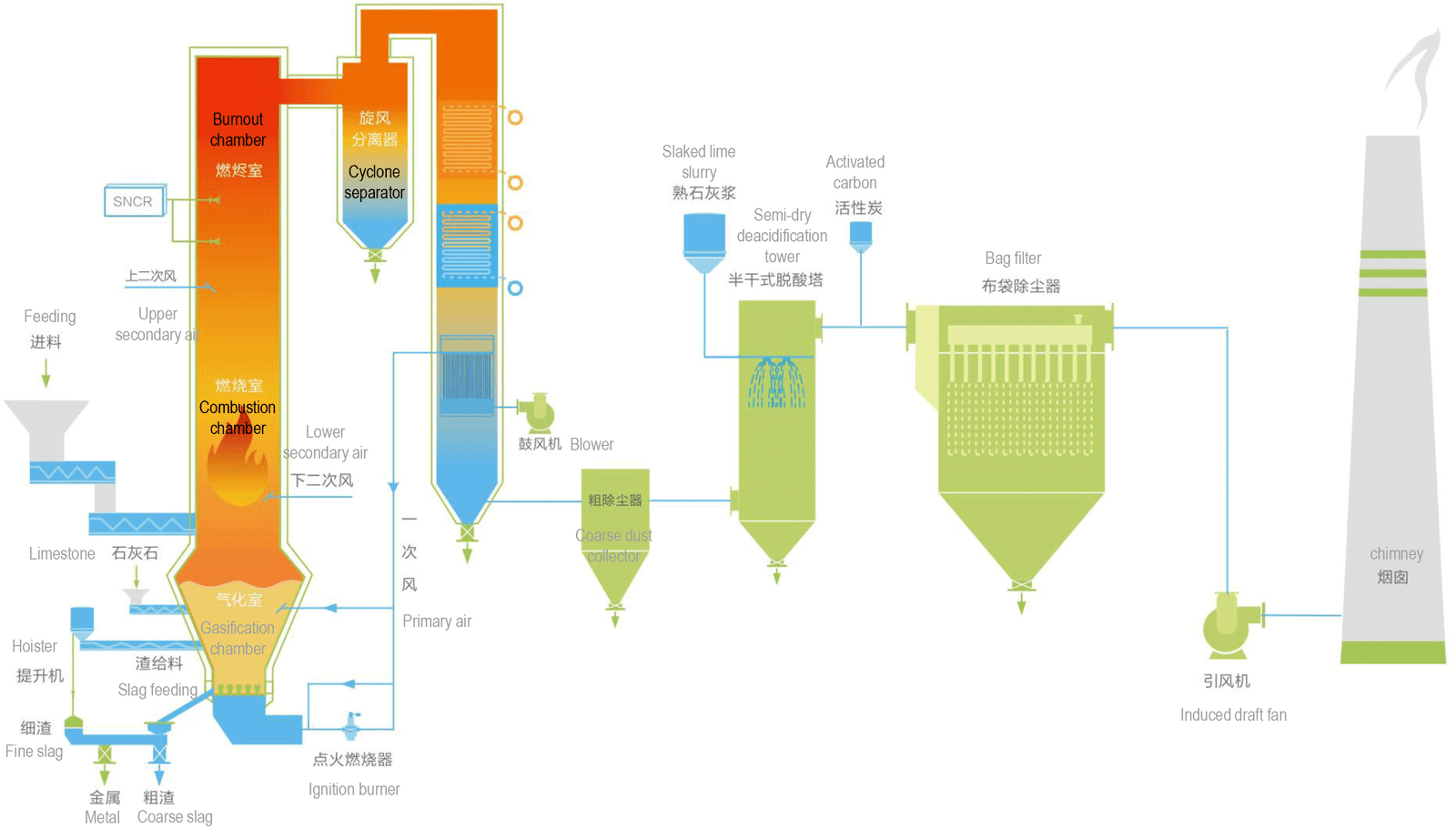

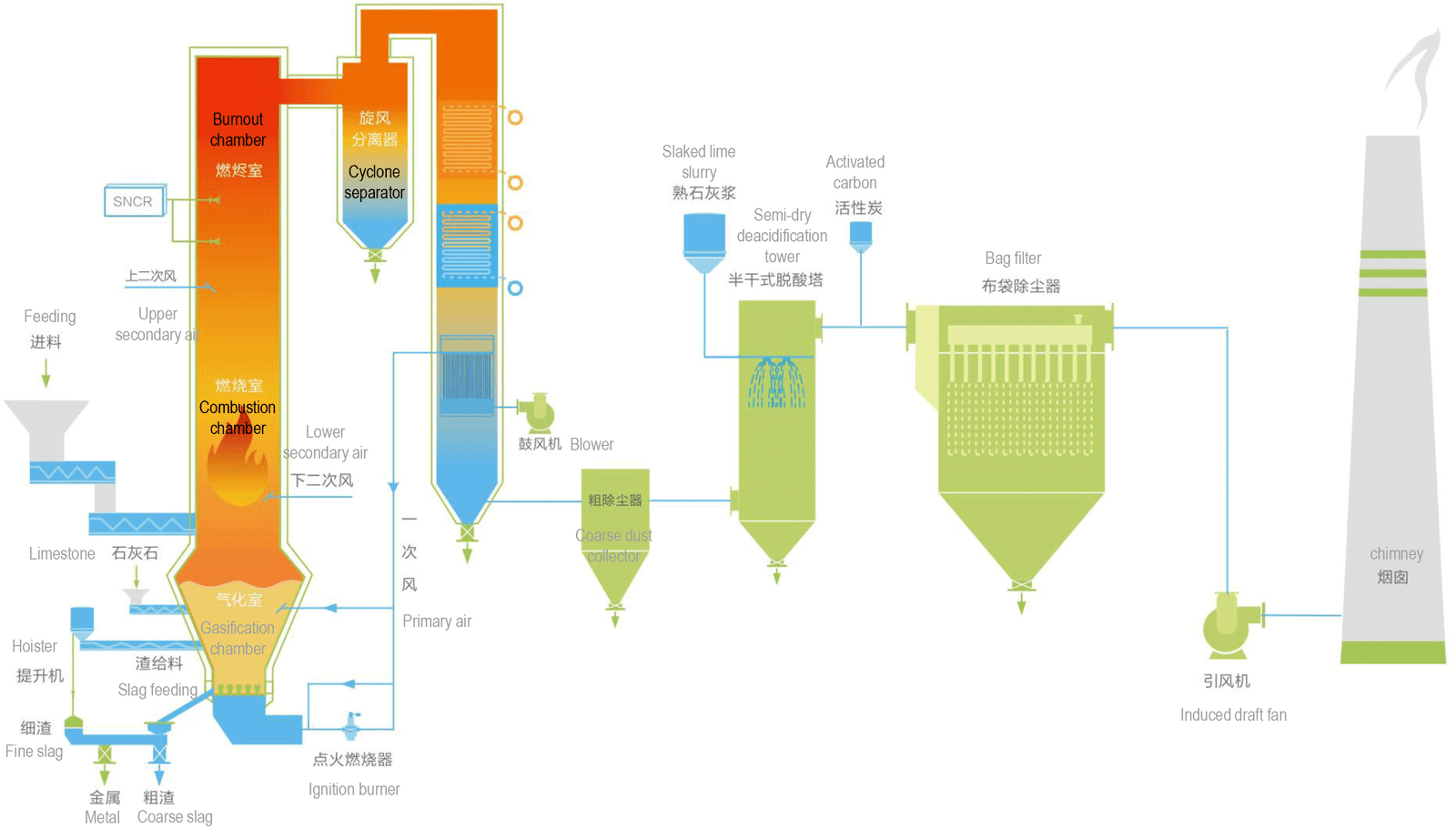

Vertical TFB gasification incineration system

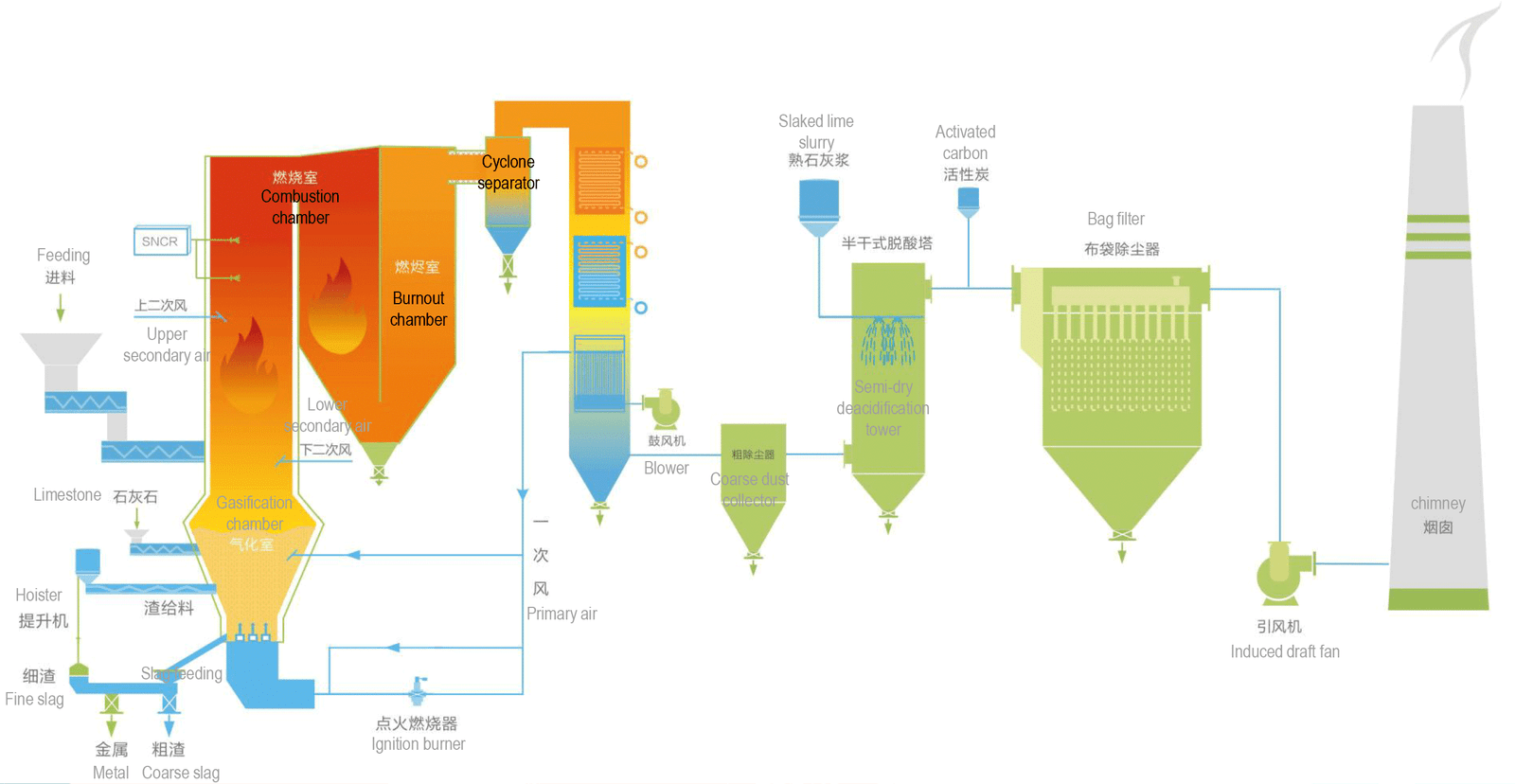

Horizontal TFB gasification incineration system

Suitable for high ash, low calorific value waste, such as sludge,domestic

garbage, etc, or the situations where the height of the venue is restricted.

Three highlights

Ultra-wide fuel adaptability

Liquid: Concentrate, waste solvent, etc.

Gas: Organic waste gas, VOCs, etc.

Slurry: Sludge, bacterial slurry, etc

Ultra-low pollutant emissions

Dust: ≤10mg/m³

SO2: ≤35mg/m³

NOX: ≤50mg/m³

CO: ≤50mg/m³

Dioxins: ≤0.05ng TEQ/m³

Heat loss rate: ≤3%

Ultra-wide load adaptability

Under the condition of mixed use of multiple fuels, the

load within the range of 40%-100% can operate

stably and meet the emission requirements. If

industrial wastes or biomass with similar properties are

used as fuels, the load adjustment range will be wider

Seven advantages

International leader

New theory, break through tradition, core patent

Exclusive solution

Data mining, precise analysis, tailormade, to provide customers with economical and applicable solutions

Double low cost

Under the same scale of pollutant emission requirements, compared with conventional technology, the initial investment is 20%-30% lower, and the operating cost is 10%-20% lower

Intelligent

Industry 4.0, high degree of automation, low operation difficulty

High stability

Annual operation is more than 8000 hours

Flexible scale

Processing capacity covers 50t/d-1000t/d

Simple system

Short process chain, simple system, no need for SCR denitration

Application scenarios

- Industrial scenario

Process waste plastic, waste rubber, waste resin, industrial sludge, etc. to generate heat

- County scenario

Process domestic waste, municipal sludge, medical waste and other production and domestic wastes, and generate heat energy

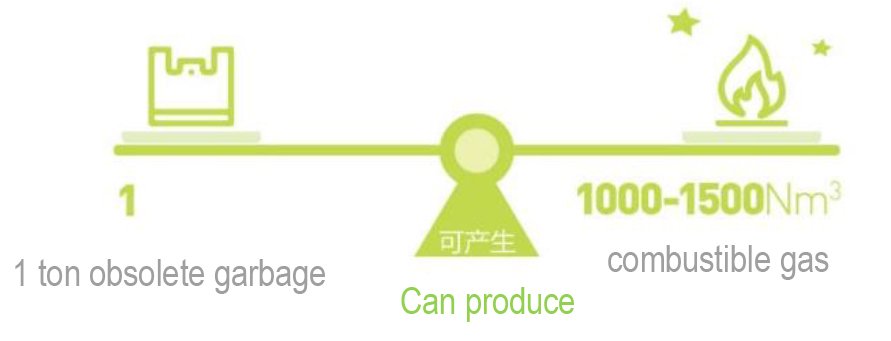

- Gasification application

Gasify obsolete garbage, biomass, waste plastics, etc. to produce combustible gas, which can be used for heating or entering a gas turbine for power generation

- Hazardous waste application

Dispose of hazardous wastes such as waste activated carbon, chemical waste residues, waste chemical solvents, gasification in the furnace and then high temperature incineration, the furnace temperature is greater than 1100 degrees, and generate heat energy

Engineering cases

Waste slag furnace equipment engineering project of a large papermaking enterprise

- Background

The raw materials of recycled paper are mostly recycled waste paper and waste paper boxes. A large amount of paper residues, mainly waste plastics, and sludge with high moisture contentare produced during the processing. They are difficult to dispose and recycle, and bring great troubles to paper companies.

1. Paper residue: Calorific value 3000-3500 kCal/Kg (mainly plastic)

2. Fine slag: Calorific value 1200-1500 kCal/Kg

3. Long slag: Calorific value 2800-3300 kCal/Kg (iron wire inside)

4. Sludge: Calorific value -200-200 kCal/Kg

Slags: 140t/d

Sludge: 110t/d

Biogas: 7000Nm³/d

- Solution

To mix the high moisture content sludge with high calorific value paper slag and biogas, the comprehensive calorific value is greater than 1600kCal/Kg, which meets the calorific value requirements, and the high-quality steam generated by incineration is reused for production.

- Customer value

- 250 tons of paper-making waste is harmless, reduced, and recycled every day.

- Annual steam production of more than 100,000 tons.

- Annual waste treatment cost savings of more than RMB 10 million.

- Annual energy cost savings of more than RMB 15 million.

- The papermaking sludge does not need to be dried, and the initial emission is low, which greatly

Industrial waste conversion steam energy project in an industrial park

- Background

There is a large amount of resin waste, resin button polishing waste, leather scraps and printing and dyeing sludge in a industrial park The nature of the raw materials is very different, so it is difficult to concentrate in the same furnace.

There are 68 enterprises that need steam in the park, and the load varies greatly from day to night. The maximum steam load is 30t/h during the day and the lowest is 3t/h at night.

It is easy to coke under high load, and the emission is easy to exceed the standard under low load, and it is difficult to operate stably

1. Resin waste: Calorific value 6000 kCal/Kg, Moisture content 3%

2. Button polishing waste: Calorific value 600 kCal/Kg, Moisture content 60%

3. Biomass pellets: Calorific value 4000 kCal/Kg, Moisture content 9%

- Solution

Utilize the TFB’s characteristics of gasification first and then incineration, to control the combustion reaction rate and ensure the stability during low-load operation.

The rated evaporation capacity is 25t/h, the rated steam pressure is increased to 2.5MPa, to meet the demand of steam load changes.

- Customer value

- Treat 10,000 to 20,000 tons of resin waste annually.

- Treat 5,000 tons of button polishing waste annually.

- Produce 150,000 tons of steam per year.

- Annual profit is more than 30 million yuan.

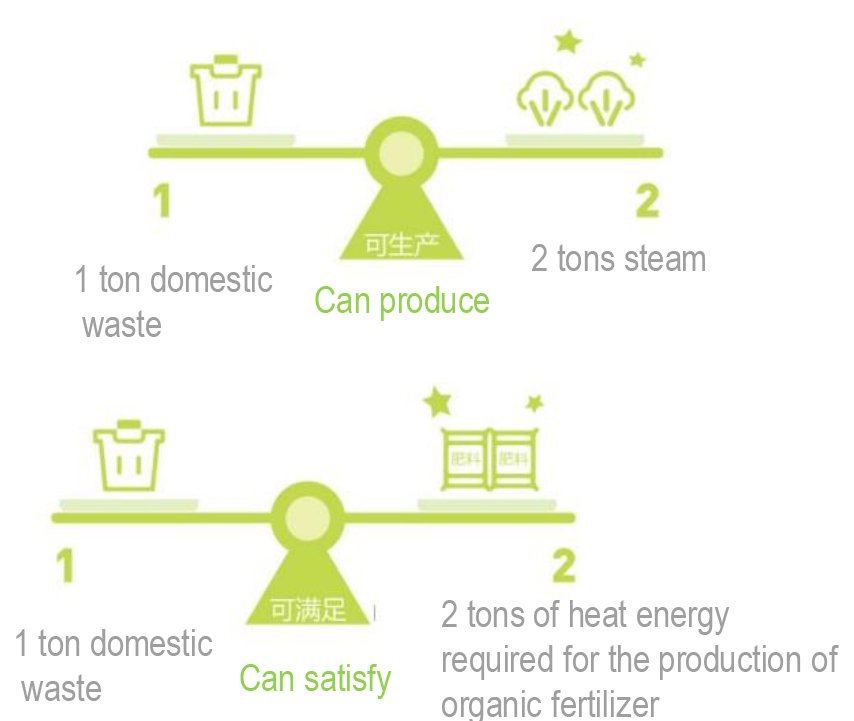

County solid waste comprehensive treatment and resource utilization project

- Background

County solid waste includes domestic garbage, municipal sludge, medical waste, obsolete garbage, straw, etc., a single type of waste is small, but the total amount is large. The composition of waste is complex, and it is difficult to burn in the same furnace.

Can not reach the scale of incineration power generation, economical is poor, and it is difficult to introduce social capital.

Miniaturized incineration technology is required, with comprehensive treatment capabilities, low unit investment and operating costs, and good pollutant emission indicators are also required.

1. Domestic garbage: Calorific value 1100-1300kCal/Kg, complex composition

2. Municipal sludge: Calorific value -200-+200 kCal/Kg, high moisture content

3. Medical waste: Calorific value 3000-5000 kCal/Kg

4. Stale garbage: Calorific value 900-51400 kCal/Kg

5. Straw: Calorific value 2500 kCal/Kg

- Solution

Utilize the TFB’s characteristics of gasification first and then incineration, to control the combustion reaction rate and ensure the stability during low-load operation.

The rated evaporation capacity is 25t/h, the rated steam pressure is increased to 2.5MPa, to meet the demand of steam load changes.

- Customer value

- Every year, 73,000 tons of wastes such as household garbage, municipal sludge, and obsolete garbage are harmless, reduced and energyized.

- 100,000 tons of planting and breeding waste are treated as resources every year.

- Relieve landfill pressure and extend the life of the landfillAnnual profit is more than 30 million yuan.

- Optimize the local business environment.

- Establish a circular economy innovation model,.

- Increase local taxes and reduce the government’s financial burden.

- ① Feeding machine

- ② Gasification chamber

- ③ Combustion chamber

- ④ Burnout chamber

- ⑤ Cyclone separator

- ⑥ Economizer

- ⑦ Chilling tower

- ⑧ Bottom slag bin

- ⑨ Activated carbon injection device

- ⑩ SNCR urea solution storage tank

- ⑪ Feeder corridor

- ⑫ Bag filter

- ⑬ Ash warehouse

- ⑭ Deacidification tower

- ⑮ CEMS

- ⑯ Chimney discharge

Contact DHB Boiler to Start Your Business

This is a new opportunity for you to make a lot of money. Seize it and let the biomass boiler start making money for you. You can recover the cost and start making money in 1 years at the earliest. Contact us immediately

© 2022 DHB Boiler LLC. All rights reserved.